Intercalation molybdenum oxide single crystal film as well as preparation method and purpose thereof

A technology of molybdenum oxide and molybdenum trioxide, applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve problems such as oxygen vacancy defects, material failure, and device response time increased to tens to hundreds of seconds , to achieve the effect of improving conductivity, expanding the interband state, and broadening the photoresponse range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation of the intercalated molybdenum oxide nanomaterial and its application in photodetectors comprises the following steps:

[0038] (1) Preparation of MoO 3 Single wafer: take 1 g of molybdenum trioxide powder (purity 99.9%) and place it in a square ceramic crucible with a length of 5 cm and a width of 2 cm. Place the crucible in a tube furnace, with both ends closed if not completely sealed, and the knobs at both ends are opened to let air in and out, and the air humidity is ~40%. Heat the crucible to 780 °C for 1 h, and use a quartz substrate to obtain MoO in the low temperature region 3 single chip.

[0039] (2) Preparation of stannous oxide solution: successively add 0.1g SnCl 2 and 1g of L-tartaric acid were added to 50mL of deionized aqueous solution and ultrasonicated for 15min to obtain 10mM SnCl 2 solution.

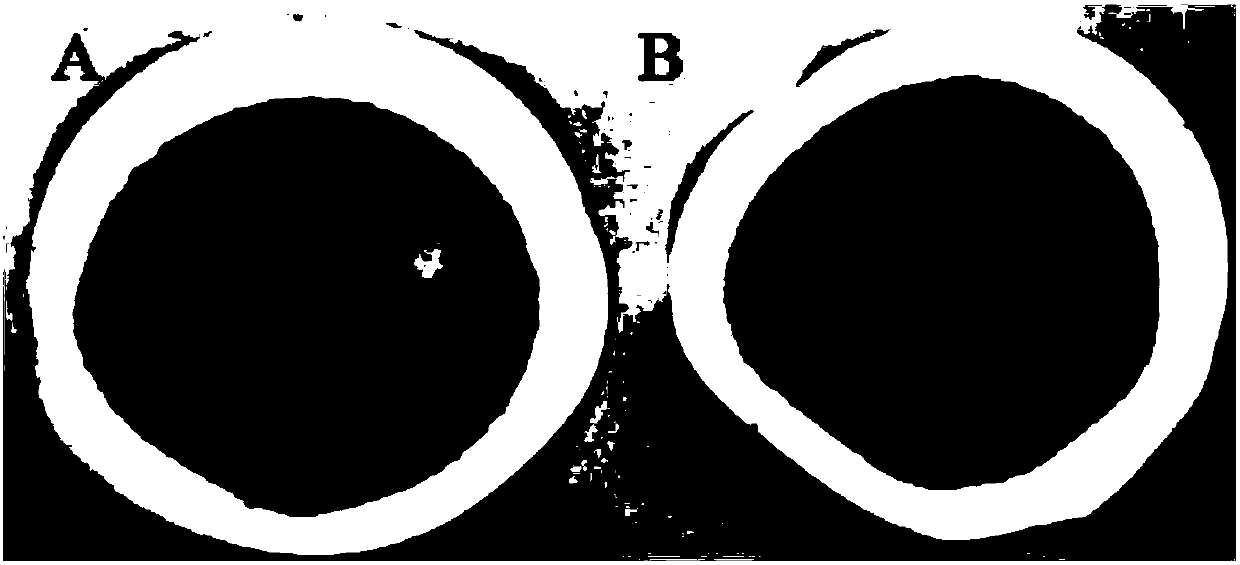

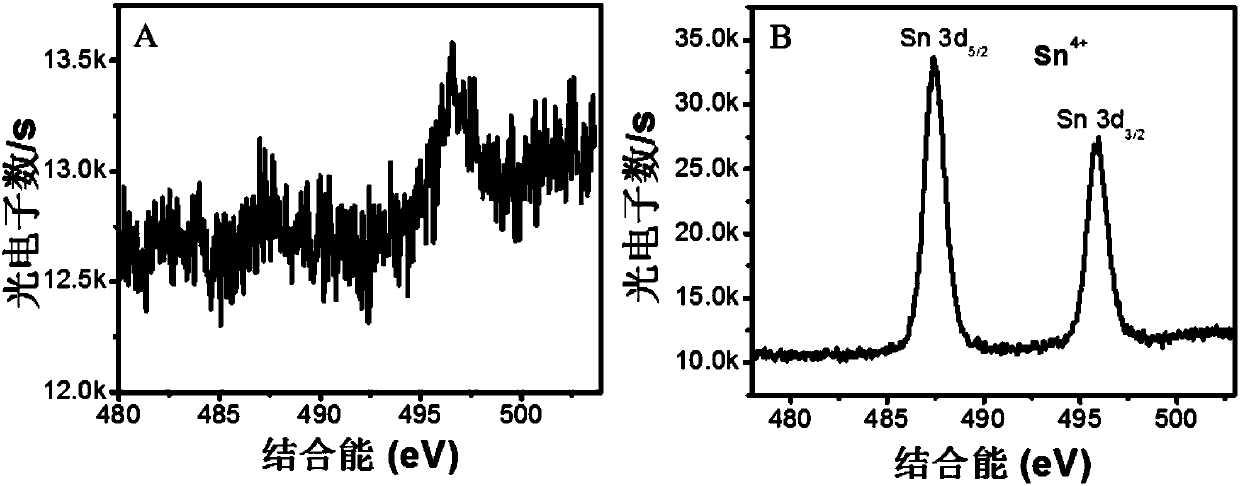

[0040] (3) Add 0.1g MoO 3The single wafer is immediately soaked in the stannous oxide solution, at this time the stannous oxide and MoO ...

Embodiment 2

[0049] The preparation of the intercalated molybdenum oxide nanomaterial and its application in photodetectors comprises the following steps:

[0050] Steps (1)-(4) are the same as in Example 1;

[0051] (5) Use a dropper to drop the intercalation molybdenum oxide single wafer suspension to 500nm thick SiO 2 On the Si wafer substrate, the dispersed doped molybdenum oxide single wafer can be obtained after natural air drying;

[0052] (6) Pass the doped molybdenum oxide single wafer through a microscopic mask, thermally evaporate a 1nm thick LiF film as an electron transport layer, and then plate a 100nm thick metal Au electrode to construct a single single wafer resistive photodetector device.

[0053] The experimental results of the response of the prepared device to the laser wavelengths of 405nm, 520nm and 638nm under the bias voltage of 0.3V and different powers are as follows: Figure 9 As shown, the results show that the prepared devices have responses at 405nm, 520nm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com