Preparation method of OCA (obeticholic acid)

A technology for obeticholic acid and a preparation process, which is applied in the field of preparation of obeticholic acid, can solve the problems of high boiling point of butyl acetate, difficult to remove, incomplete configuration transformation, and reduced product purity, and achieves safe, non-toxic solvent, Short production cycle and good stereoselectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

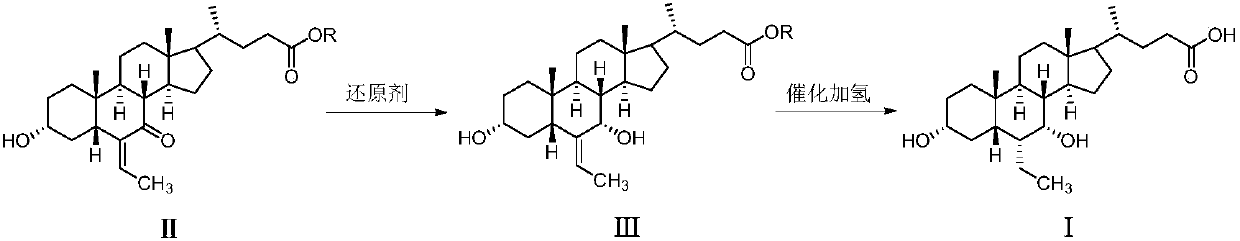

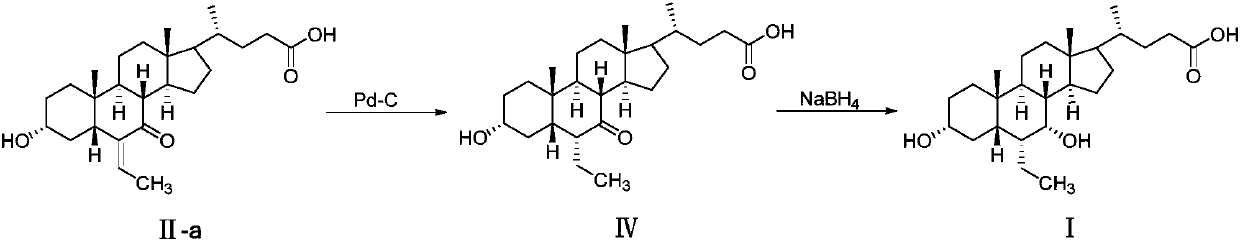

Method used

Image

Examples

Embodiment 1

[0030] Preparation of (E)-3α,7α-dihydroxy-6-ethylene-5β-cholan-24-acid

[0031] Add (E)-3α-hydroxy-6-ethylene-7-keto-5β-cholan-24-acid (100.0g, 0.26mol) and methanol (1.0L) to the reaction flask, cool to 0°C, Sodium borohydride (22.7 g, 0.60 mol) was added, the addition was completed, and the reaction was carried out at 30° C. for 3 hours. Cool to 0°C, dropwise add 1.0 mol / L hydrochloric acid to adjust pH to 4, add ethyl acetate (1.0L) and water (1.0L), separate liquids, and evaporate the organic phase to dryness under reduced pressure at 40°C. Dichloromethane (1.5L) was added, heated at 40°C and stirred for 30 minutes, cooled to 10°C, stirred for 2 hours, filtered, and the filter cake was dried at 40°C to obtain a white solid, namely (E)-3α,7α-dihydroxy-6- Ethylene-5β-cholan-24-acid (98.8 g, purity: 99.7%, yield: 90.8%).

Embodiment 2

[0033] Preparation of (E)-3α,7α-dihydroxy-6-ethylene-5β-cholan-24-acid ethyl ester

[0034] Add (E)-3α-hydroxy-6-ethylene-7-one-5β-cholan-24-acid ethyl ester (50.0g, 0.11mol), tetrahydrofuran (400.0ml) and absolute ethanol to the reaction flask (100.0ml), cooled to 0°C, sodium borohydride (12.5g, 0.33mol) was added, the addition was completed, and the reaction was carried out at 0°C for 3 hours. Cool to 0°C, add 1.0mol / L hydrochloric acid dropwise to adjust pH to 7, add ethyl acetate (500.0ml) and water (500.0ml), separate the liquids, and evaporate the organic phase to dryness under reduced pressure at 40°C. Ethyl acetate (500.0ml) was added, heated at 50°C and stirred for 30 minutes, cooled to 10°C, stirred for 2 hours, filtered, and the filter cake was dried at 60°C to obtain an off-white solid, namely (E)-3α,7α-dihydroxy-6 - Ethylene-5β-cholan-24-acid ethyl ester (46.5 g, purity: 99.3%, yield: 92.5%).

Embodiment 3

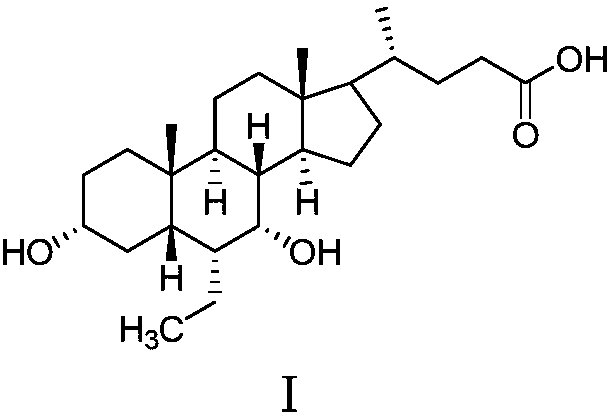

[0036] Preparation of obeticholic acid

[0037] Add (E)-3α,7α-dihydroxy-6-ethylene-5β-cholane-24-acid (95.0g, 0.23mol), sodium hydroxide (18.4g, 0.16mol), water to the reaction flask (750 mL) and 5% palladium on carbon (9.5 g), the reaction mixture was heated to 30° C. under the pressure of 1 to 3 atmospheres, and the hydrogen was no longer absorbed after 5 hours of hydrogenation reaction. The reaction solution was filtered, water (675 mL) was added to the filtrate, and the temperature was raised to 50°C. Add 1.0mol / L hydrochloric acid solution dropwise to adjust pH to 3.0, continue to keep stirring for 30min, cool to 10°C and stir for crystallization for 2 hours, filter, and vacuum dry the filter cake at 50°C for 3 hours to obtain a white solid, namely obeticholic acid ( 80.9 g, purity: 99.89%, yield: 84.8%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com