A kind of fiber raw liquid color paste and preparation method thereof

A color paste and fiber technology, which is applied in the field of preparation of new environment-friendly fiber stock solution color paste, can solve the problems of environment and operator injury, production personnel injury, and hidden dangers of cancer, and achieve novel methods, reduced pollution, and small particle size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

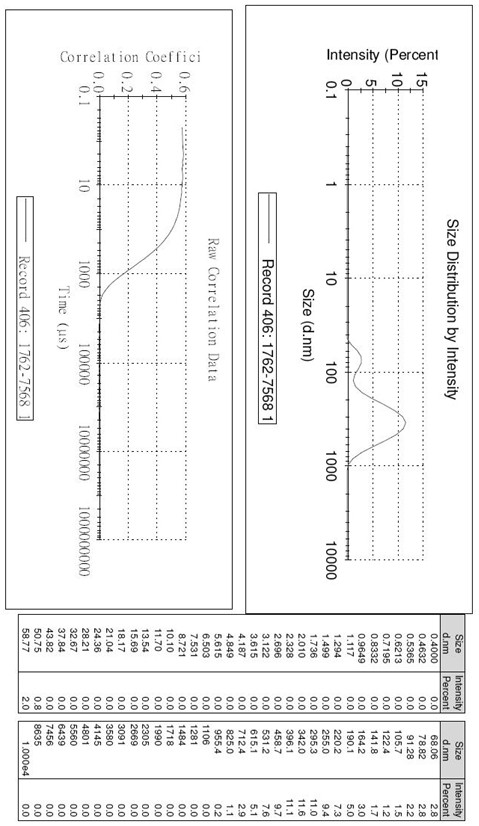

Image

Examples

Embodiment 1

[0035] A new type of fiber stock solution color paste, prepared from pre-emulsion, adipic hydrazide aqueous solution and initiator solution as raw materials:

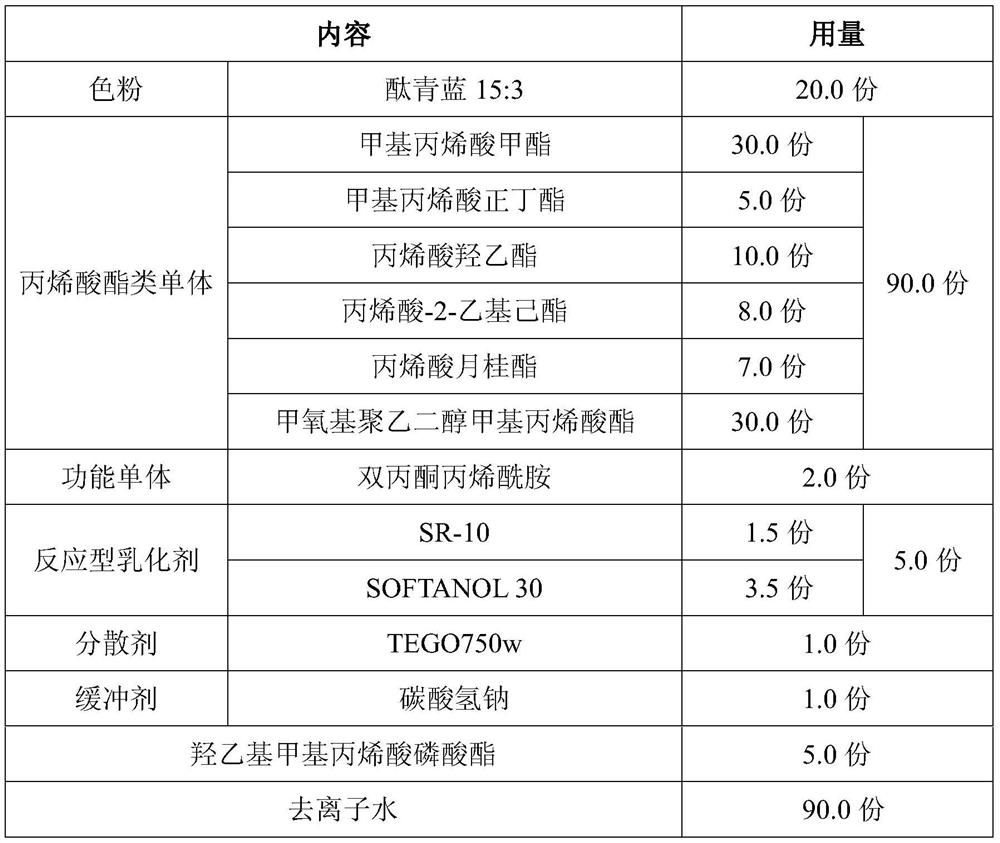

[0036] The pre-emulsion is prepared from the raw materials of the following parts by mass shown in Table 1:

[0037]

[0038] Table 1

[0039] The concentration of the aqueous solution of adipic hydrazide was 8 wt%.

[0040] The initiator solution is obtained by mixing 1.2 parts by mass of potassium persulfate, 1.0 parts by mass of sodium bisulfite, 12.8 parts by mass of deionized water, and 2.0 parts by mass of propylene glycol.

[0041] A preparation method for fiber stock liquid color paste, comprising the steps of:

[0042] 1) Weigh the toner phthalocyanine blue 15:3, dispersant TEGO750w, reactive emulsifier, water, mix and ultrasonically disperse for 0.5h, then add buffer sodium bicarbonate, special monomer hydroxyethyl methacrylate phosphate and deionized water, mixed and stirred for ultrasonic emulsificatio...

Embodiment 2

[0047] A new type of fiber stock solution color paste, prepared from pre-emulsion, adipic hydrazide aqueous solution and initiator solution as raw materials:

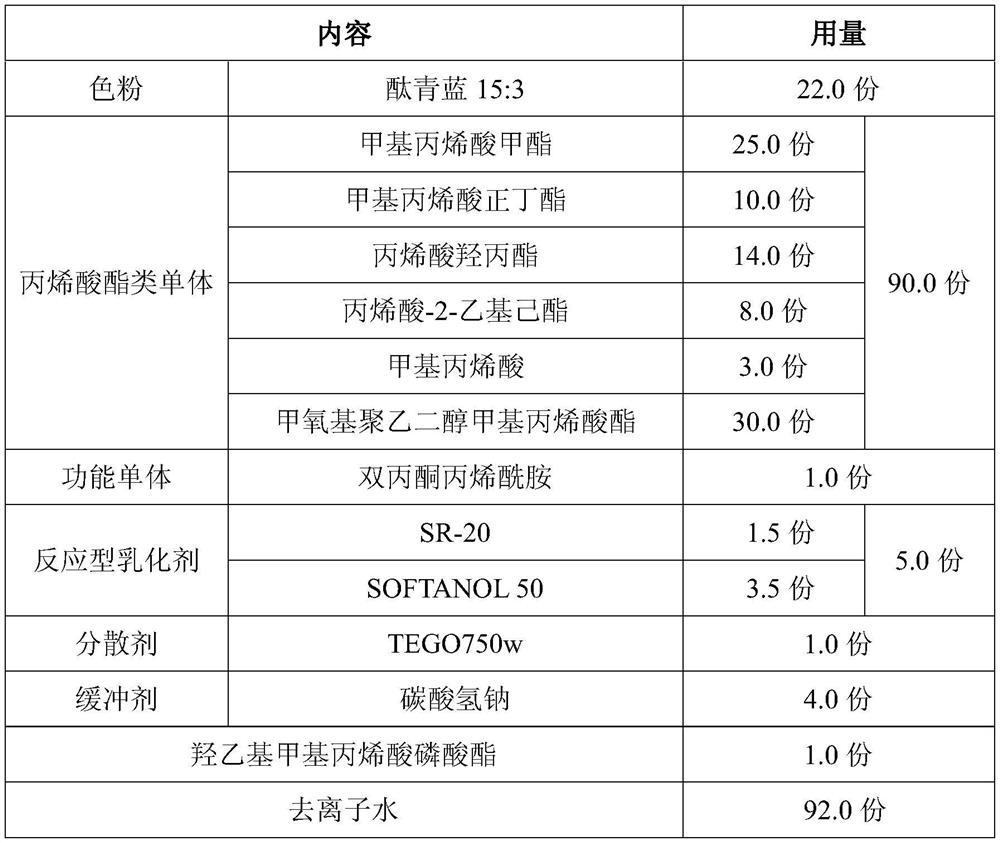

[0048] The pre-emulsion is prepared from the raw materials of the following parts by mass shown in Table 2:

[0049]

[0050] Table 2

[0051] The aqueous solution of adipic hydrazide is obtained by dissolving 0.8-1.6 parts by mass of adipic hydrazide in 8-10 parts of deionized water.

[0052] The initiator solution is obtained by mixing 1.2 parts by mass of potassium persulfate, 1.0 parts by mass of sodium bisulfite, 12.8 parts by mass of deionized water, and 2.0 parts by mass of propylene glycol.

[0053] A preparation method of a new type of fiber stock solution color paste, the difference from Example 1 is that step (1) ultrasonic emulsification for 0.5h, to obtain a pre-dispersion.

Embodiment 3

[0055] A new type of fiber stock solution color paste, prepared from pre-emulsion, adipic hydrazide aqueous solution and initiator solution as raw materials:

[0056] The pre-emulsion is prepared from the raw materials of the following parts by mass shown in Table 3:

[0057] table 3

[0058]

[0059]

[0060] The aqueous solution of adipic hydrazide is obtained by dissolving 0.8-1.6 parts by mass of adipic hydrazide in 8-10 parts of deionized water.

[0061]The initiator solution is obtained by mixing 1.2 parts by mass of potassium persulfate, 1.0 parts by mass of sodium bisulfite, 12.8 parts by mass of deionized water, and 2.0 parts by mass of propylene glycol.

[0062] The preparation method is different from Example 1 in that after adding 20% acrylate monomer in step (2), heat to 55°C, add the remaining acrylate monomer and initiator solution dropwise, and start the function of dropping at the same time When monomer is used, the temperature is controlled at 60°C....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com