Early-strength expansion delayed type hole sealing material

A sealing material and strong expansion technology, applied in the field of sealing materials, can solve the problem that mining sealing materials cannot be directly dosed on site, and achieve the effect of improving expansion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

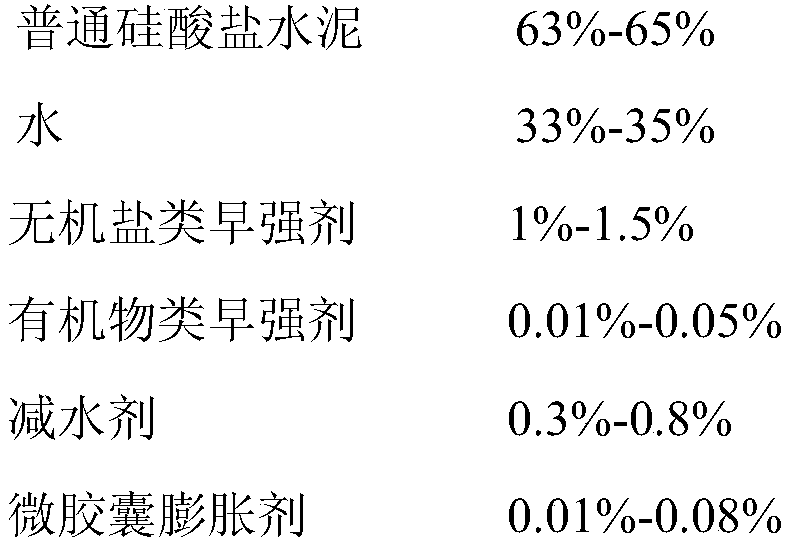

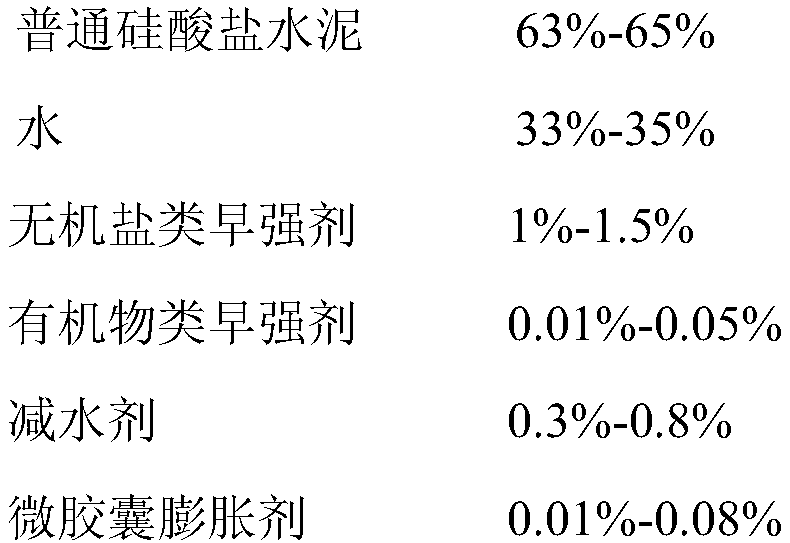

[0023] Ordinary Portland cement: 63%; Water: 35%; Sodium chloride: 0.3%; Sodium sulfate: 0.3%; Triethanolamine: 0.04%; AMPS: 0.7%; Sodium aluminate: 0.6%; 0.06%; mix the above substances according to mass percentage.

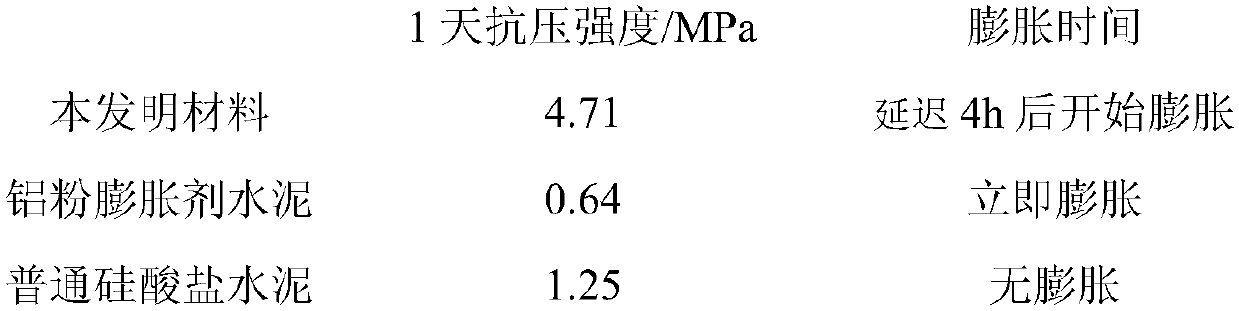

[0024] Use the sealing material of the present invention, ordinary Portland cement, and aluminum powder expansion agent cement to conduct tests on early strength and expansion time. See Table 1:

[0025] Table 1 Experimental results of sealing material properties

[0026]

[0027] Analysis of Table 1 shows that:

[0028] Compared with ordinary Portland cement, this material has improved compressive strength, and the one-day compressive strength is 3.8 times that of ordinary Portland cement. increase in magnitude. On the one hand SO 4 2- Hydration reaction product Ca(OH) with cement 2 The reaction produces highly dispersed calcium sulfate, which is easier to react with the cement component tricalcium aluminate than the added calcium sulfate to form need...

Embodiment 2

[0031] Ordinary Portland cement: 63%; Water: 35%; Sodium chloride: 0.4%; Sodium sulfate: 0.4%; Triethanolamine: 0.03%; AMPS: 0.6%; Sodium aluminate: 0.5%; 0.07%; the above substances are mixed and used according to the mass percentage, the expansion delay time is 225min, and the 1-day compressive strength is 4.31MPa.

Embodiment 3

[0033] Ordinary Portland cement: 65%; Water: 33%; Sodium chloride: 0.3%; Sodium sulfate: 0.3%; Triethanolamine: 0.04%; AMPS: 0.7%; Sodium aluminate: 0.6%; 0.06%; the above substances are mixed according to the mass percentage, the expansion delay time is 252min, and the 1-day compressive strength is 4.05MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com