Preparation method of high temperature resistance phenolic resin binder

A technology of phenolic resin and binder, which is applied in the field of phenolic resin preparation, can solve problems such as poor high temperature resistance, and achieve the effects of increasing thermal decomposition temperature, inhibiting chain scission, and increasing the carbon residue rate of resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

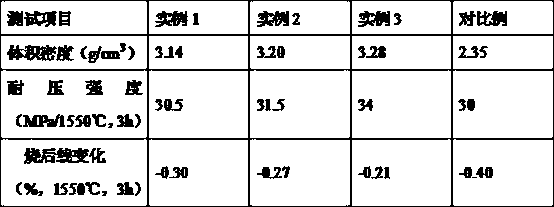

Examples

example 1

[0020] Weigh 400g of magnesite ore, put the magnesite ore into a stone grinder and grind for 2 hours to obtain magnesium ore particles with a particle size of 1mm, put the magnesium ore particles into a calciner, heat up to 700°C, and heat-preserve and calcinate for 8 hours , to obtain light-burned magnesia ore, put light-burned magnesia ore into a mortar and grind for 2 hours, pass through a 100-mesh standard sieve to obtain sieved magnesium ore powder; weigh 200g of molybdenite ore and put it in a high-temperature furnace, and put it into a high-temperature furnace under the condition of introducing air , heat up to 200°C, heat-preserve and roast for 3 hours to obtain roasted molybdenite, pour the roasted molybdenite into a beaker, soak and roast the molybdenite with 300mL of ammonia water with a mass fraction of 40% for 4 hours, and obtain a mixed solution. Adjust the pH value of the mixed liquid in the beaker to 40% nitric acid solution to 6.5, filter and remove the filtrat...

example 2

[0022] Weigh 450g of magnesite ore, put the magnesite ore into a stone grinder and grind for 2.5h to obtain magnesium ore particles with a particle size of 2mm, put the magnesium ore particles into a calciner, heat up to 750°C, and heat-preserve and calcinate for 9h Finally, light burnt magnesia ore is obtained, put the light burnt magnesia ore into a mortar and grind for 2.5 hours, pass through a 100-mesh standard sieve to obtain sieved magnesium ore powder; weigh 250g of molybdenite ore and put it into a high temperature furnace, Under certain conditions, heat up to 225°C, heat-preserve and roast for 4 hours to obtain roasted molybdenite, pour the roasted molybdenite into a beaker, soak and roast the molybdenite with 350 mL of ammonia water with a mass fraction of 40% for 5 hours, and obtain a mixed solution. The nitric acid solution with a mass fraction of 40% adjusted the pH value of the mixed solution in the beaker to 6.7, filtered and removed the filtrate to obtain a filt...

example 3

[0024]Weigh 500g of magnesite ore, put the magnesite ore into a stone grinder and grind for 3 hours to obtain magnesium ore particles with a particle size of 3mm, put the magnesium ore particles into a calciner, heat up to 800°C, and heat-preserve and calcinate for 10 hours , to obtain light-burned magnesia ore, put the light-burned magnesia ore into a mortar and grind for 3 hours, pass through a 100-mesh standard sieve to obtain sieved magnesia ore powder; weigh 300g of molybdenite ore and put it in a high-temperature furnace, , heat up to 250°C, heat-preserve and roast for 5 hours to obtain roasted molybdenite, pour the roasted molybdenite into a beaker, soak and roast the molybdenite with 400mL ammonia water with a mass fraction of 40% for 6 hours, and obtain a mixed solution. Adjust the pH of the mixture in the beaker to 7.0 for 40% nitric acid solution, filter the filtrate to obtain the filter residue, wash the filter residue with deionized water for 5 times, put the washe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com