Polyether sulfone grafted acrylic monomer copolymer and preparation method thereof

An acrylic and polyethersulfone technology, which is applied in the field of polyethersulfone grafted acrylic monomer copolymer and its preparation, can solve the problem that the grafting rate loses the thermodynamic advantage of the rigid molecular chain of PES, the molecular chain is not fully opened, and is prone to occur. Cross-linking phenomenon and other problems, to achieve the effect of improving hydrophilic properties, good solubility, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

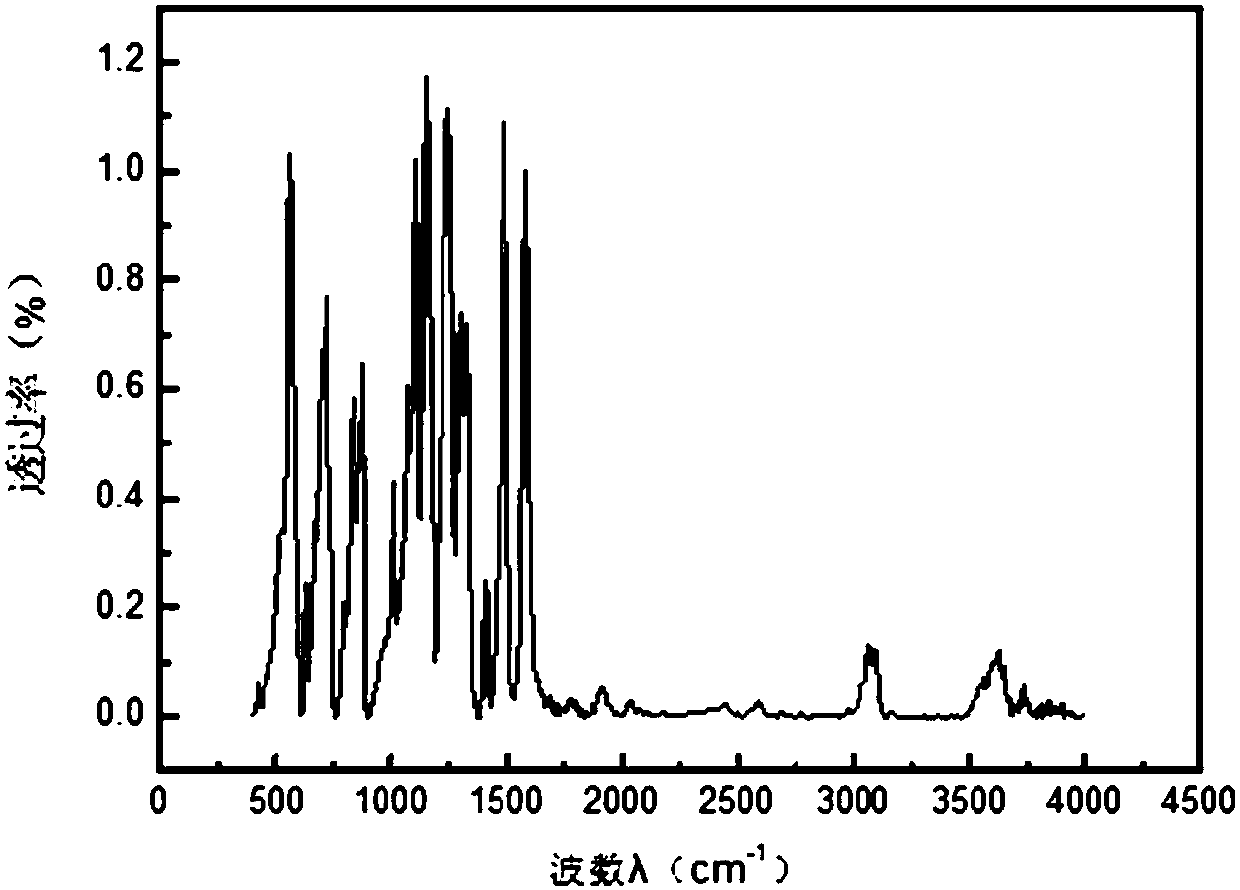

[0044] Accurately weigh 10 g of pretreated PES powder, dissolve it in 89.6 g of DMF solvent, add 0.4 g of MAA monomer (the mass ratio of PES to MAA is 5:0.2), and stir at 60°C for 24 hours to obtain a homogeneous solution; Access to N 2 After 15 min, the homogeneous solution was placed in 60 C O Under the source, the irradiation reaction was carried out at 20°C, the irradiation dose rate was 1kGy / h, and the absorbed dose was 17kGy.

[0045] After the irradiation reaction, the homogeneous solution was reverse-precipitated in an aqueous solution, washed several times, soaked in deionized water for 24 hours, and dried in a vacuum oven (80° C.) to constant weight. The grafting ratio (abbreviated as DG) of the product analyzed by elemental analysis and blending infrared standard curve was 1.6%.

Embodiment 2

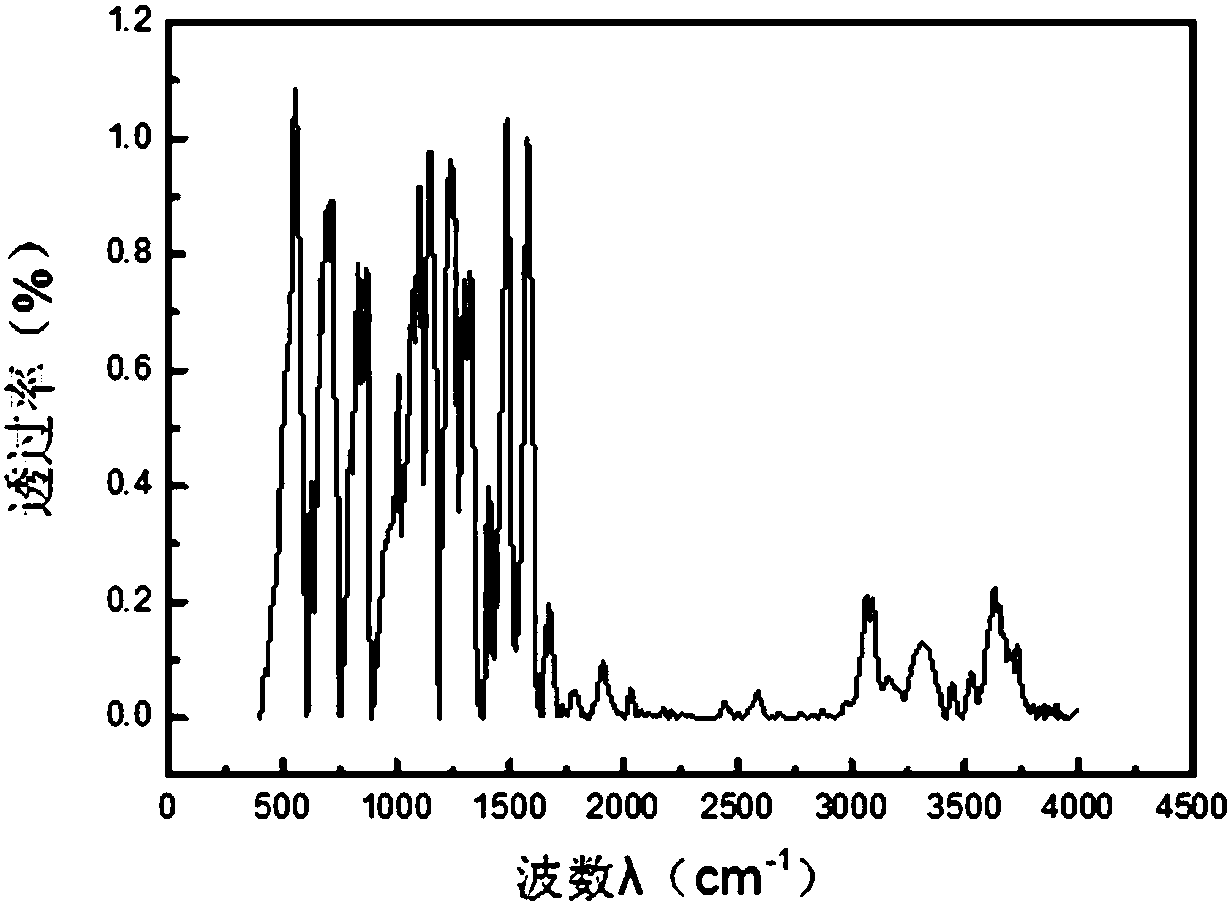

[0047] Accurately weigh 10g of the pretreated PES powder, dissolve it in 89.2g of DMF solvent, add 0.8g of MAA monomer (the mass ratio of PES to MAA is 5:0.4), and stir at 60°C for 24h to obtain a homogeneous solution; Access to N 2 After 15 min, the homogeneous solution was placed in 60 C O Under the source, the irradiation reaction was carried out at 20°C, the irradiation dose rate was 1kGy / h, and the absorbed dose was 17kGy.

[0048] After the irradiation reaction, the homogeneous solution was reverse-precipitated in an aqueous solution, washed several times, soaked in deionized water for 24 hours, and dried in a vacuum oven (80° C.) to constant weight. The grafting rate of the product was 3.68% analyzed by elemental analysis and infrared standard curve of blending method.

Embodiment 3

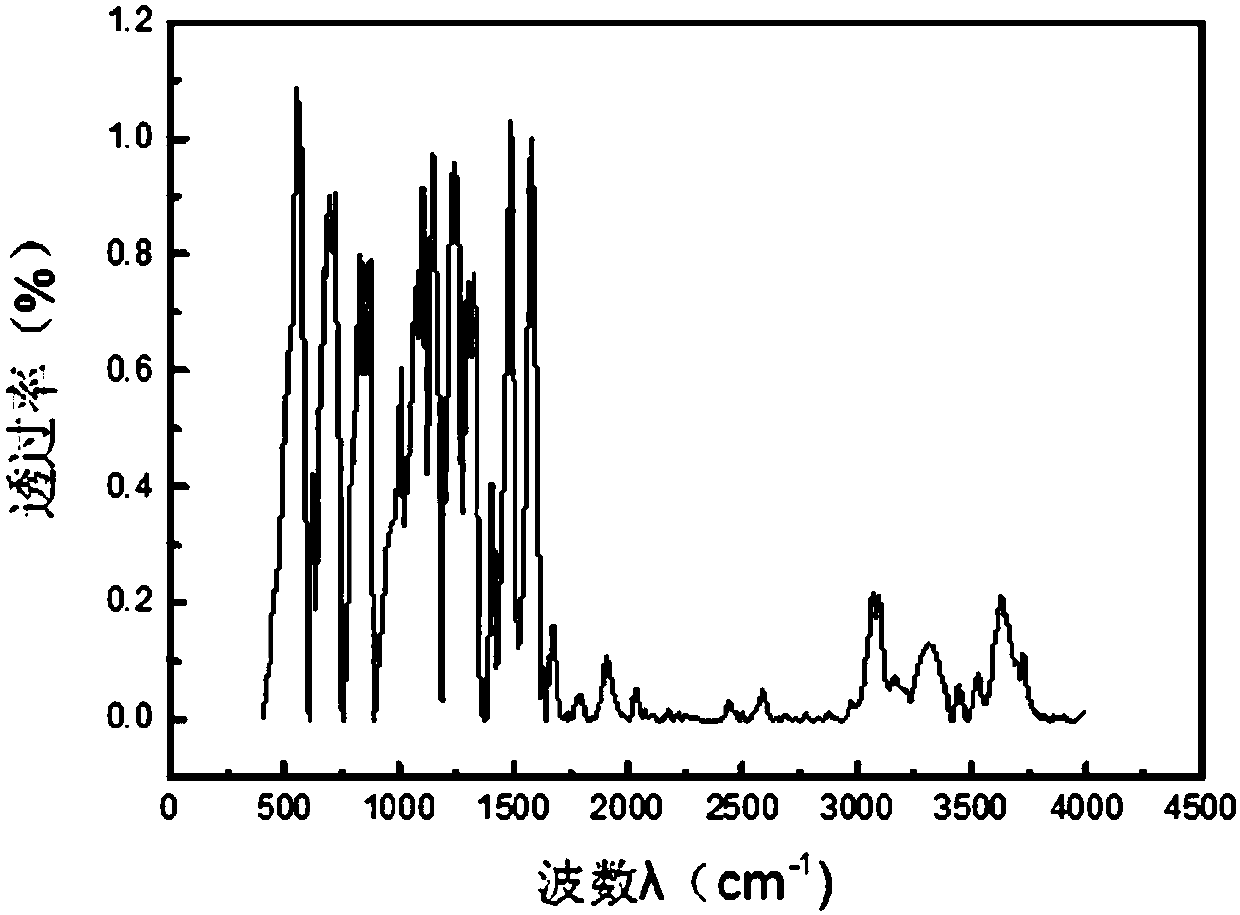

[0050] Accurately weigh 10g of the pretreated PES powder, dissolve it in 88.4g of DMF solvent, add 1.6g of MAA monomer (the mass ratio of PES to MAA is 5:0.8), and stir at 60°C for 24h to obtain a homogeneous solution; Access to N 2 After 15 min, the homogeneous solution was placed in 60 C O Under the source, the irradiation reaction was carried out at 20°C, the irradiation dose rate was 1kGy / h, and the absorbed dose was 17kGy.

[0051] After the irradiation reaction, the homogeneous solution was reverse-precipitated in an aqueous solution, washed several times, soaked in deionized water for 24 hours, and dried in a vacuum oven (80° C.) to constant weight. The grafting rate of the product was 6.3% analyzed by elemental analysis and infrared standard curve of blending method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com