Synthesis method of CQD (carbon quantum dot) quaternary ammonium salt cationic surfactant

A technology of quaternary ammonium salt cation and surfactant, which is applied in the direction of cationic surface active compound, detergent composition, detergent compounding agent, etc. The effect of biocompatibility, simple synthesis steps, and easy manipulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

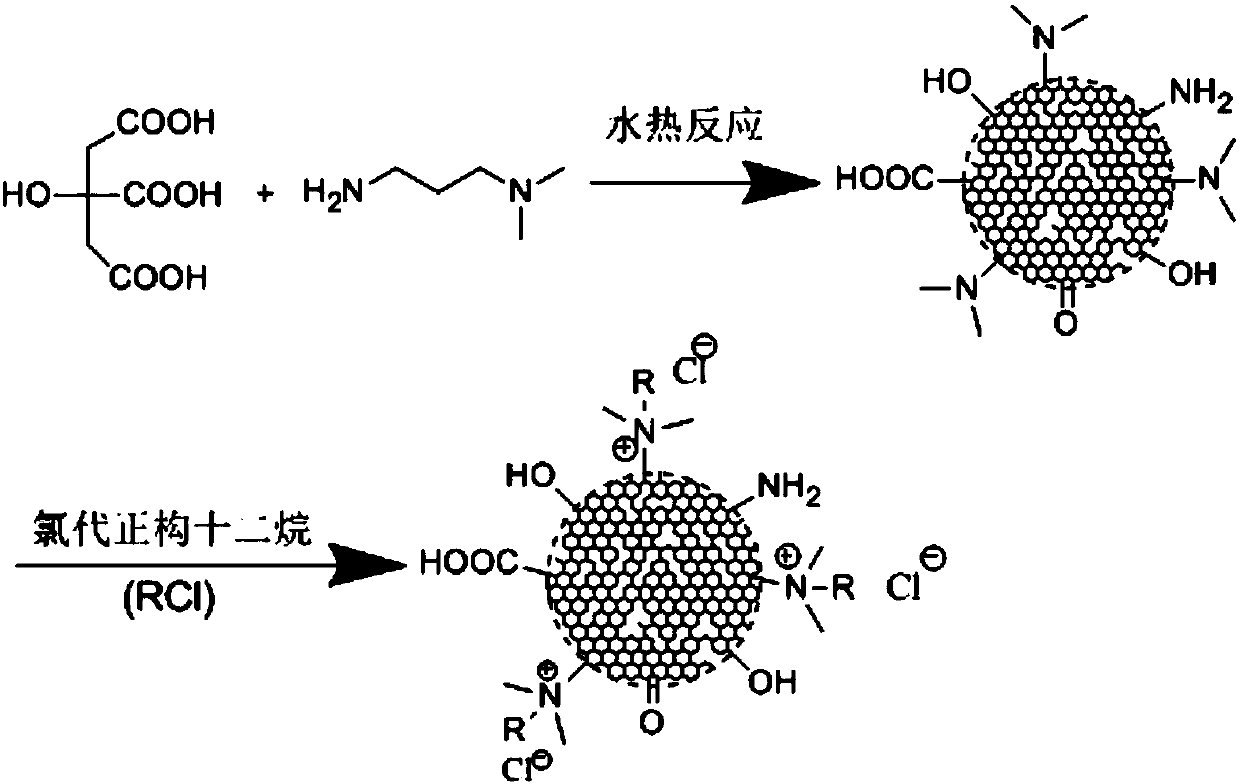

[0044] (1) Weigh 60g (0.31mol) of citric acid, dissolve it in 100mL of distilled water, add 1.71mol of 3-dimethylaminopropylamine, mix well, transfer to a hydrothermal reaction kettle, react at 170°C for 80min, then cool to room temperature;

[0045] (2) The product in (1) is subjected to vacuum distillation to recover excess amine, and the product is placed in a drying oven at 70° C. to dry to obtain fluorescent carbon quantum dots;

[0046] (3) Dissolve the product in (2) in ethanol aqueous solution (90%, w%), add chlorinated n-dodecane according to the molar ratio of 3.30:1 with citric acid, heat and reflux under stirring, and the reaction temperature is 70° C., Reaction time 3.0h;

[0047] (4) The crude product obtained in (3) is subjected to vacuum distillation, reclaims excess ethanol, and adds a small amount of water, separates excess chloro-n-alkane, and recycles;

[0048] (5) The product in (4) is dried in an oven at 70° C. to obtain a carbon quantum dot cationic su...

Embodiment 2

[0050] (1) Weigh 60g (0.31mol) of citric acid, dissolve it in 100mL of distilled water, add 1.71mol of N,N-dimethylethylenediamine, mix well, transfer to a hydrothermal reaction kettle, and react at 175°C for 65min , and then cooled to room temperature;

[0051] (2) with step (2) in embodiment 1;

[0052] (3) Dissolve the product in (2) in aqueous ethanol (92%, w%), add chloro-n-tetradecane in a molar ratio of 2.80:1 with citric acid, heat to reflux under stirring, and the reaction temperature is 70° C., Reaction time 2.5h;

[0053] (4) with step (4) in embodiment 1;

[0054] (5) Same as step (5) in Example 1.

Embodiment 3

[0056] (1) Weigh 60g (0.31mol) of citric acid, dissolve it in 100mL of distilled water, add 2.01mol of 4-dimethylaminobutylamine, mix well, transfer to a hydrothermal reaction kettle, react at 180°C for 70min, and then Cool to room temperature;

[0057] (2) with step (2) in the embodiment;

[0058] (3) Dissolve the product in (2) in aqueous ethanol (94%, w%), add chloro-n-tetradecane in a molar ratio of 3.00:1 with citric acid, heat to reflux under stirring, and the reaction temperature is 70° C., Reaction time 2.5h;

[0059] (4) with step (4) in embodiment 1;

[0060] (5) Same as step (5) in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com