A method for preparing a new type of cable

A new type of cable technology, applied in the field of cable materials and cable materials with composite protective layers, can solve the problems of insufficient resistance performance and insufficient design of cable materials, achieve strong temperature effects, ensure application safety, and prevent defects. produced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

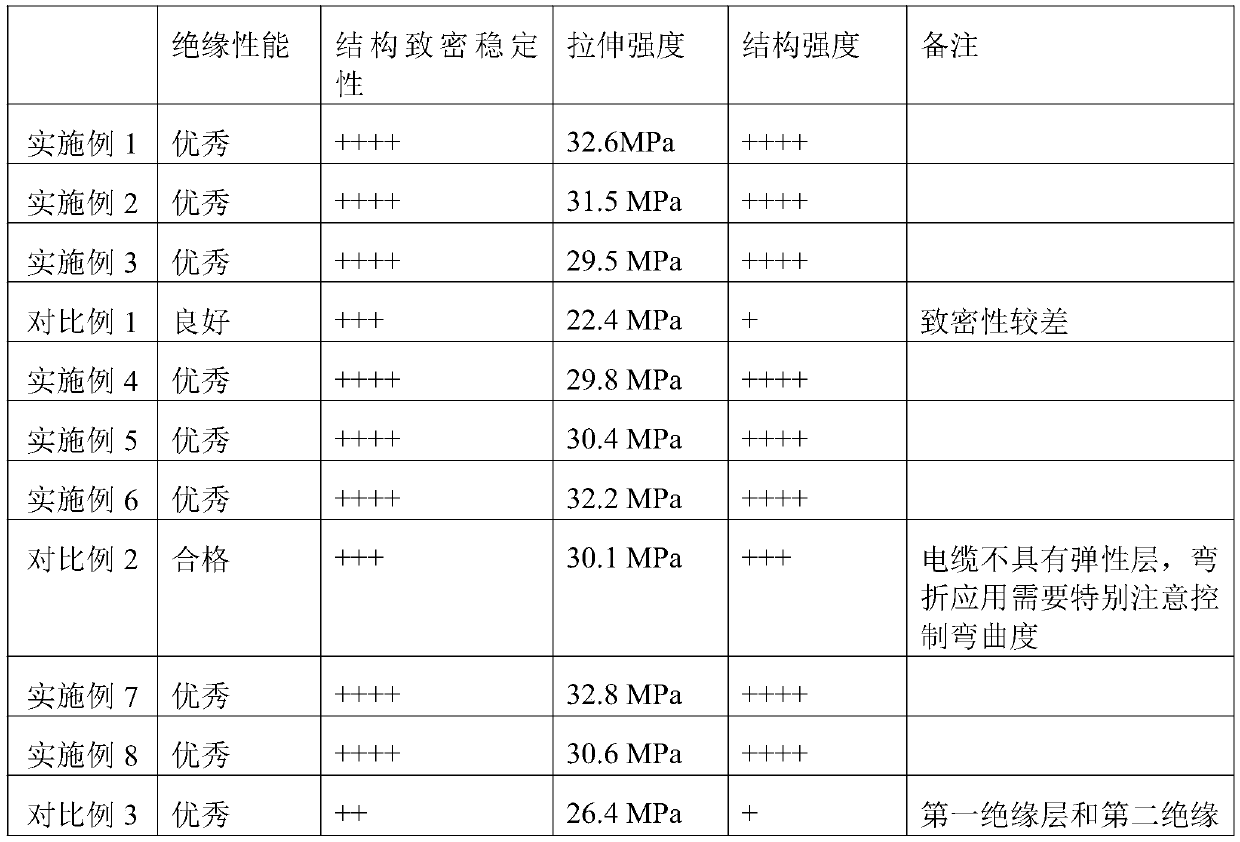

Examples

Embodiment 1

[0040] A new type of cable, including a pure copper conductive core, a first insulating layer, a second insulating layer, an elastic layer and a sheath. The thickness ratio of each layer is 13:3:18:3:6. The first insulating layer is made of a polymer material mixture with the following composition by weight: polypropylene: epoxy resin: polyamide: phenolic resin = 3:1:1:1. The second insulating layer is made of a polymer material mixture of the following components: polyethylene, polypropylene and monosilane, and the weight ratio of polyethylene is 5:5:0.01. The elastic layer is made of polyvinyl chloride and polyurethane mixture, the ratio of the two is 2:9, the porosity of the elastic layer is 7.6v%, and the diameter of the cavity is 3-5μm. The shell is made of polyvinyl chloride.

Embodiment 2

[0042] The new cable consists of a pure copper conductive core, a first insulating layer, a second insulating layer, an elastic layer and a shell. The thickness ratio of each layer is 14:2:18:4:7. The first insulating layer is made of the following polymer material mixture in parts by weight: 8 parts of polypropylene, 2 parts of epoxy resin, 1 part of polyamide, and 0.5 part of polyester. The second insulating layer is made of the following polymer raw material mixture in parts by weight: 10 parts of polyethylene, 10 parts of polypropylene, 0.5 part of polyvinyl chloride and 0.05 part of disilane. The elastic layer is made of polyvinyl chloride and polyurethane mixture, the ratio of the two is 1:6, the porosity of the elastic layer is 4.5v%, and the diameter of the cavity is 2-4μm. The shell layer is made of raw material mixture of polyvinyl chloride and polyethylene in a ratio of 1:1 by weight.

Embodiment 3

[0044] A new type of cable, including a pure copper conductive core, a first insulating layer, a second insulating layer, an elastic layer and a sheath. The thickness ratio of each layer is 12:2:15:4:7. The first insulating layer is made of a polymer material mixture with the following components: polypropylene: epoxy resin, phenolic resin = 4:2:1. The second insulating layer is made of a polymer material mixture of the following composition: polyethylene:polypropylene = 1:1 mixture as a base material, with the addition of 0.4% monosilane (relative to the second insulating layer mixture). The elastic layer is made of polyvinyl chloride and polyurethane mixture, the ratio of the two is 2:7, the porosity of the elastic layer is 6.9v%, and the diameter of the cavity is 1-3μm. The shell is made of polyvinyl chloride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com