High-transparency super-definition high-strength film and preparation method thereof

A film-adhering and high-definition technology, which is applied in the field of high-transparency, ultra-clear, high-strength film and its preparation, can solve the problems of low film strength, achieve high transparency and clarity, good dispersion, and alleviate aging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

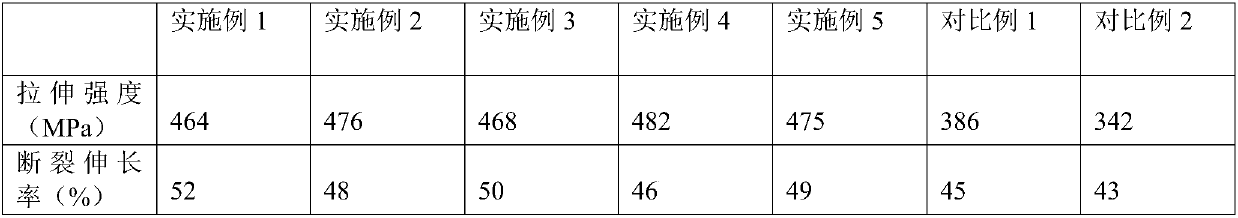

Examples

Embodiment 1

[0023] A high-transparency, ultra-clear and high-strength film, the film raw materials include the following components in parts by weight: 60 parts of polyvinyl acetate resin, 2 parts of 2-tert-butyl-4-methyl-6 ethylphenol, 3-(methyl 3 parts of acryloyloxy)propyltrimethoxysilane, 2 parts of 2-hydroxy-4-n-octyloxybenzophenone, 5 parts of sorbitol monolaurate, 1 part of reinforcing agent and ethylene bis Stearamide 3 parts.

[0024] The enhancer is pretreated, and the pretreatment method includes the following steps:

[0025] 1) After mixing 2g of kaolin and 1g of silica fume, add 30% of the mixed weight of water, then heat treatment at 130°C for 4 hours, then cool to room temperature, and grind to 150 mesh to obtain a mixture of kaolin and silica fume ;

[0026] 2) Add 1g of calcium carbonate into the kaolin and silica fume mixture in step 1) and mix evenly, add 35% of its weight in water, then heat treatment at 100°C for 3 hours, then cool to room temperature, and grind to ...

Embodiment 2

[0033] A high-transparency, ultra-clear and high-strength film, the film raw materials include the following components in parts by weight: 62 parts of polyvinyl acetate resin, 3 parts of 2-tert-butyl-4-methyl-6 ethylphenol, 3-(methyl 3 parts of acryloyloxy)propyltrimethoxysilane, 2 parts of 2-hydroxy-4-n-octyloxybenzophenone, 6 parts of sorbitol monolaurate, 1 part of reinforcing agent and ethylene bis Stearamide 4 parts.

[0034] The enhancer is pretreated, and the pretreatment method includes the following steps:

[0035] 1) After mixing 2.2g of kaolin and 1.3g of silica fume, add water of 31% by weight of the mixed weight, then heat treatment at 135°C for 5 hours, then cool to room temperature, and grind to 160 mesh to obtain kaolin and silica fume mix;

[0036] 2) Add 1.2g of calcium carbonate into the kaolin and silica fume mixture in step 1) and mix evenly, add 36% water by weight, heat treatment at 102°C for 3 hours, then cool to room temperature, and grind to 260 m...

Embodiment 3

[0042]A high-transparency, ultra-clear and high-strength film, the film raw materials include the following components in parts by weight: 65 parts of polyvinyl acetate resin, 3.5 parts of 2-tert-butyl-4-methyl-6 ethylphenol, 3-(methyl Acryloyloxy)propyltrimethoxysilane 4 parts, 2-hydroxy-4-n-octyloxybenzophenone 3 parts, sorbitol monolaurate 6.5 parts, enhancer 2 parts and ethylene bis 4.5 parts of stearylamide.

[0043] The enhancer is pretreated, and the pretreatment method includes the following steps:

[0044] 1) After mixing 2.5g of kaolin and 2g of silica fume, add 32% water of the mixing weight, then heat treatment at 140°C for 6 hours, then cool to room temperature, and grind to 165 mesh to obtain kaolin and silica fume mixture material;

[0045] 2) Add 1.5g of calcium carbonate into the kaolin and silica fume mixture in step 1) and mix evenly, add 37% water by weight, heat treatment at 105°C for 4 hours, then cool to room temperature, and grind to 270 meshes to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com