Device for treating waste gas by microwave plasma

A technology of microwave plasma and gas treatment, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of unstable discharge, extinguishing of plasma discharge, and low utilization rate of unit energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

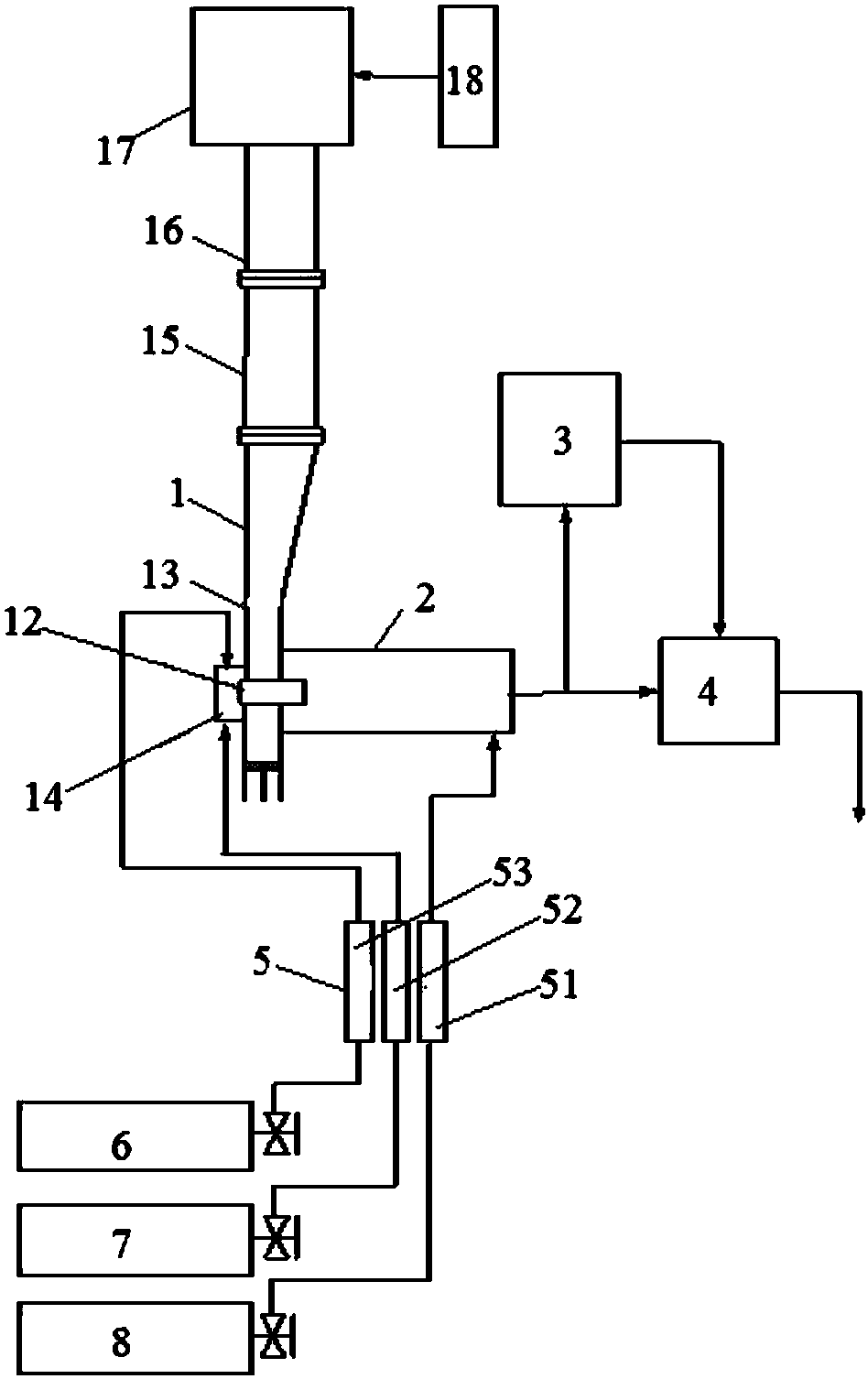

[0022] The present invention is a device for treating waste gas based on microwave plasma, which mainly includes a microwave plasma generator 1 , a device for entering gas to be treated 2 , a gas detection system 3 and a tail gas treatment system 4 .

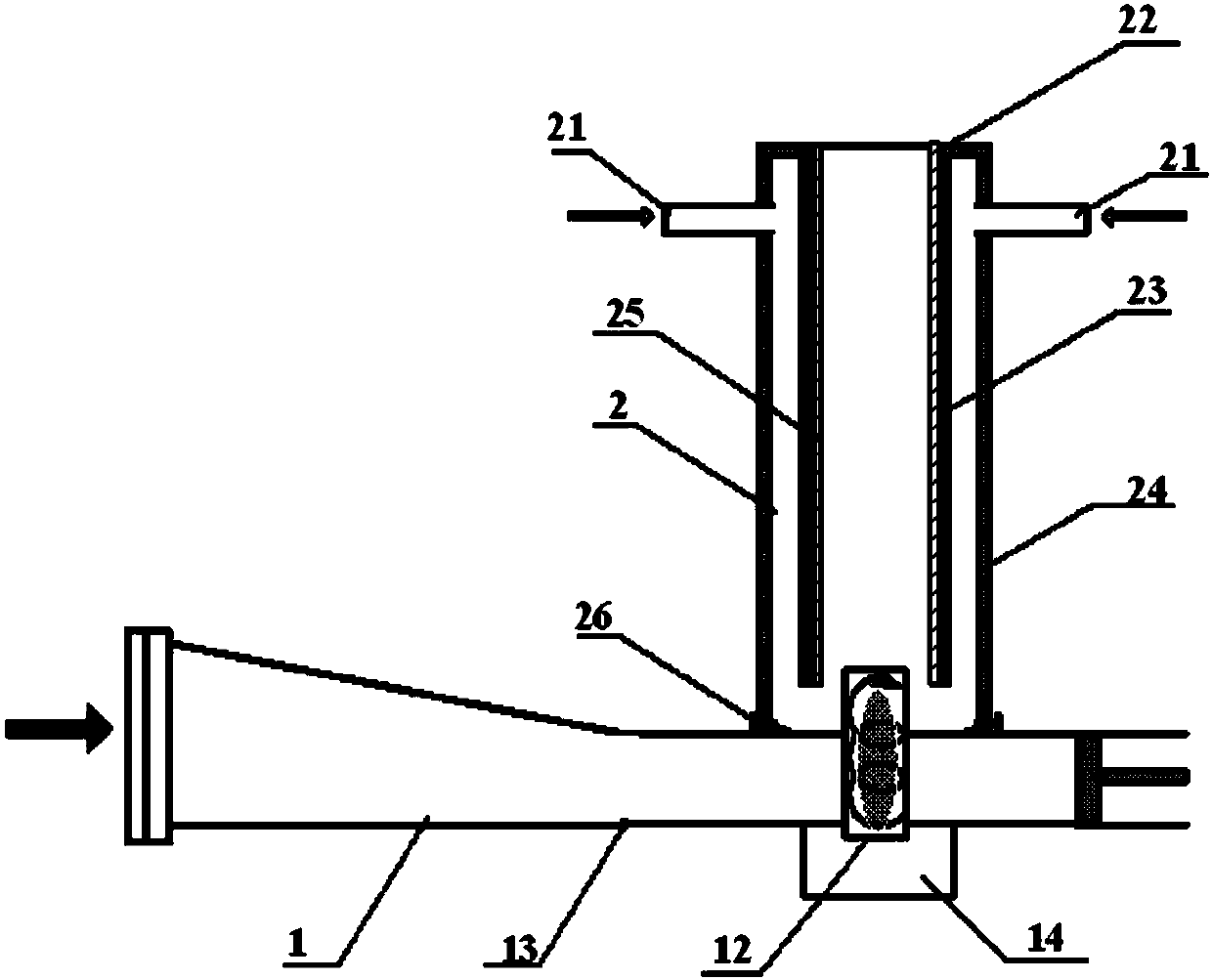

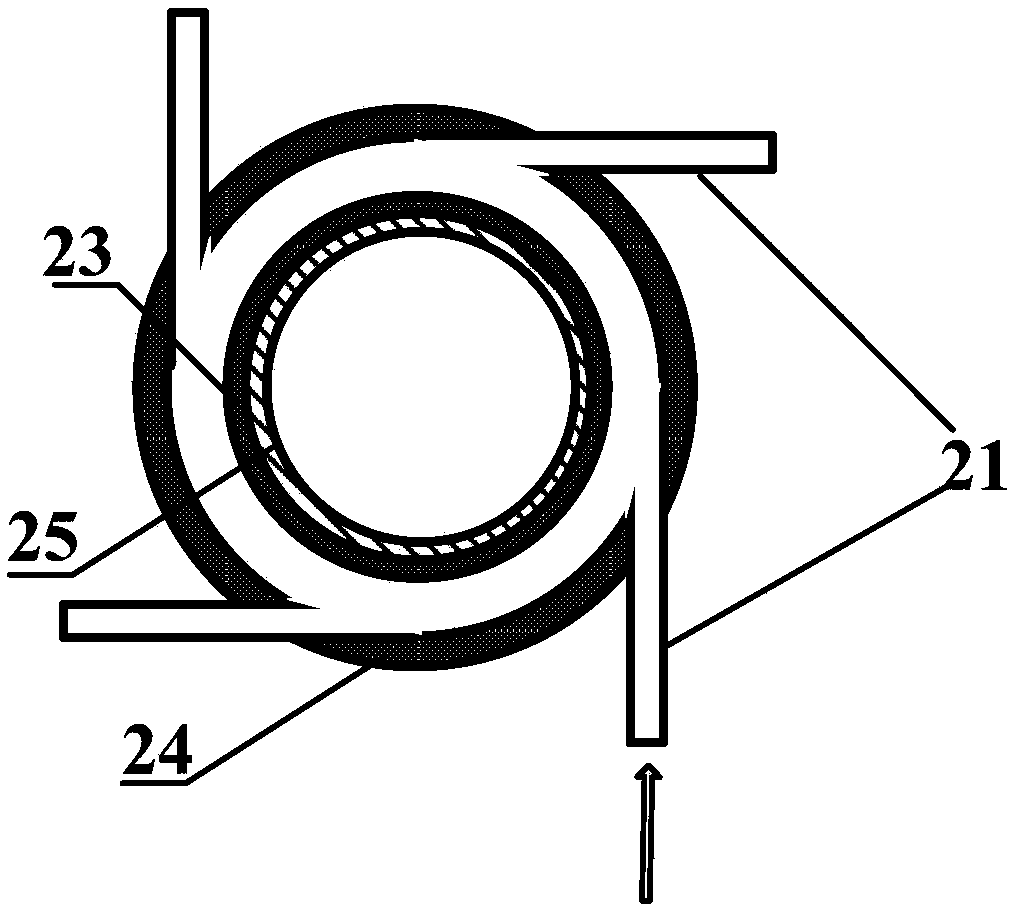

[0023] The microwave plasma generator 1 is mainly responsible for causing the first and second working gases 6 and 7 to excite plasma discharge in the discharge tube 12 under atmospheric pressure, maintain the plasma state under the coupling of microwave power, and drive the The microwave plasma coupling waveguide 13 downstream of the discharge tube 12 forms a thermal plasma torch. The gas to be treated entering device 2 is responsible for introducing the exhaust gas 8 that needs to be treated into the area where it interacts with the plasma torch, and introduces the gas to be treated 8 to the downstream outlet of the discharge tube 12 in the form of a vortex flow, so that the gas to be treated 8 and the plasma torch generated b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com