Ultra-clean environment-friendly treatment island for tail gas of coal-fired boiler

A technology for coal-fired boilers and exhaust gas, applied in fixed tubular conduit components, lighting and heating equipment, combined devices, etc., can solve the problems of reducing cooling and heating effects, easy to exceed, poisoning, etc., and achieve reasonable structural design and effective use Highlight and reduce the effect of environmental protection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

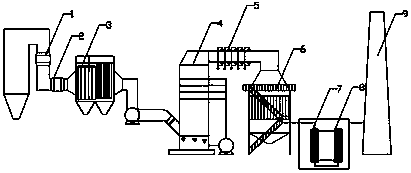

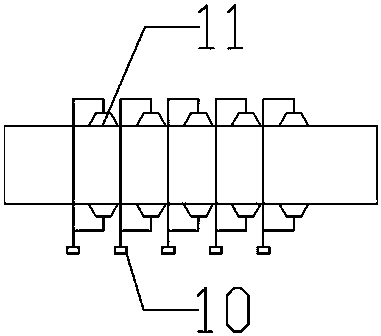

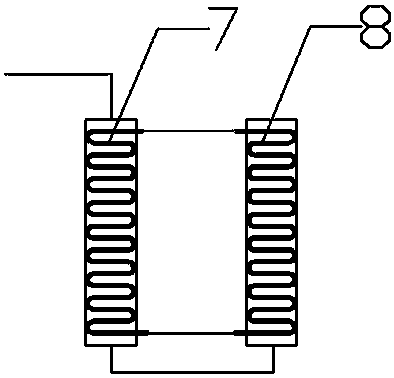

[0025] The invention provides a coal-fired boiler ultra-clean environment-friendly treatment island. The boiler preheater is connected with a denitrification device 1, followed by a waste heat absorption device 2, a dry dust collector 3, a desulfurization device 4, an ultrasonic condensing device 5, Wet electrostatic precipitator 6, cooling MGGH7 and heating MGGH8, the integration and mutual coupling of various devices form a complete and efficient flue gas treatment system for capturing fine particles PM2.5 and dehumidification, desalination and dewhitening. The denitrification device 1 is non-selective catalysis Denitrification SNCR or selective catalytic denitrification SCR, the denitrification device realizes that the emission of nitrogen oxides NOX is less than or equal to 50mg / Nm 3 , and then the flue gas passes through the waste heat absorption device 2 and then enters the dry dust collector 3. The waste heat absorption device 2 is a low-temperature economizer, which red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com