Hard alloy resistant to high pressure and high temperature and preparation method thereof

A cemented carbide and high-pressure-resistant technology, which is applied in the field of powder metallurgy, can solve the problems of high price and high cobalt content, and achieve the effects of reducing test costs, inhibiting plastic deformation, and saving rare metal resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

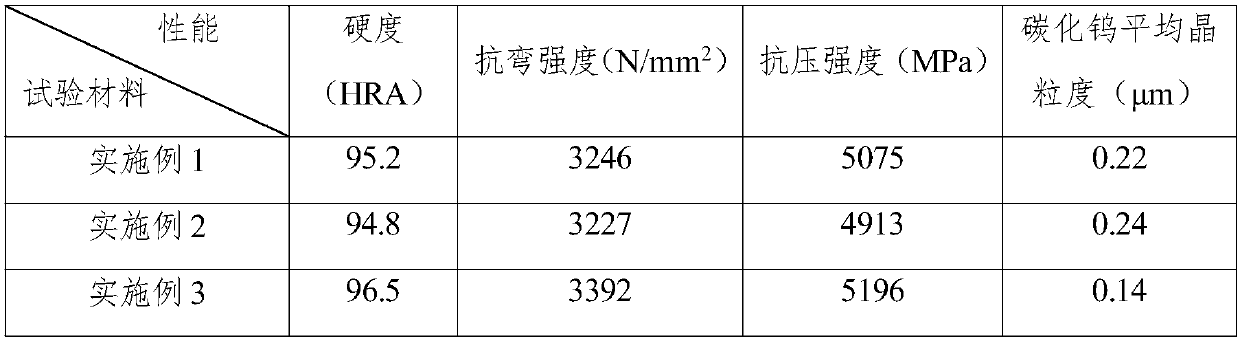

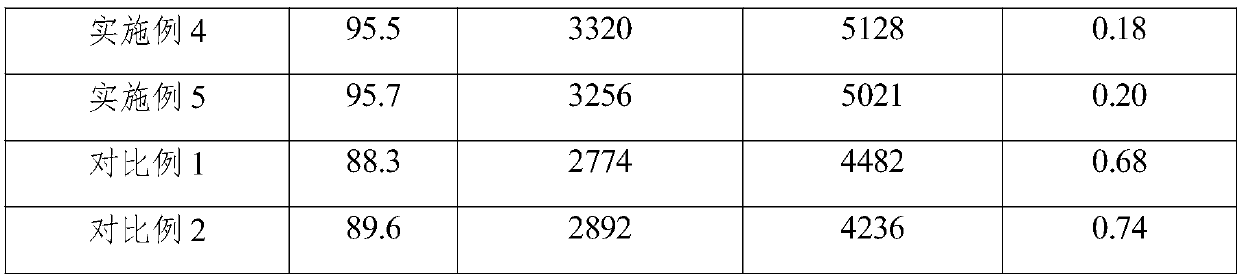

Examples

Embodiment 1

[0045] Embodiment 1, high pressure and high temperature hard alloy

[0046] The high-pressure and high-temperature cemented carbide is composed of the following components and their mass parts: 0.1 part of cobalt with a particle size of 0.3 μm, 0.1 part of rhodium with a particle size of 0.4 μm, and 1.0 part of carbonyl nickel powder with a particle size of 0.45 μm , 1.0 parts of vanadium carbide with a particle size of 0.15 μm, 10 parts of tantalum carbide with a particle size of 0.4 μm, 0.6 parts of niobium carbide with a particle size of 0.4 μm, 2.0 parts of titanium carbide with a particle size of 0.2 μm, and a particle size of 0.1 μm 0.3 parts of hafnium carbide, 0.1 part of aluminum nitride with a particle size of 0.3 μm, and 75 parts of tungsten carbide with a particle size of 0.25 μm.

[0047] Preparation:

[0048] S1: Take all the raw materials according to the specified mass parts, mix them evenly, add ball milling medium and place it in a ball mill for ball milling...

Embodiment 2

[0052] Embodiment 2, high pressure and high temperature hard alloy

[0053] The high-pressure and high-temperature cemented carbide is composed of the following components and their mass parts: 1.0 part of cobalt with a particle size of 0.6 μm, 0.3 part of rhodium with a particle size of 0.6 μm, and 0.5 part of carbonyl nickel powder with a particle size of 0.65 μm , 0.1 parts of vanadium carbide with a particle size of 0.6 μm, 20 parts of tantalum carbide with a particle size of 0.8 μm, 1.0 parts of niobium carbide with a particle size of 1 μm, 4.0 parts of titanium carbide with a particle size of 0.8 μm, and 0.5 parts of hafnium carbide, 0.5 parts of aluminum nitride with a particle size of 0.6 μm, and 90 parts of tungsten carbide with a particle size of 0.35 μm.

[0054] Preparation:

[0055] S1: Take all the raw materials according to the specified mass parts, mix them evenly, add ball milling medium and place it in a ball mill for ball milling. The ball milling medium is...

Embodiment 3

[0059] Embodiment 3, high pressure and high temperature hard alloy

[0060] The high-pressure and high-temperature cemented carbide is composed of the following components and their mass parts: 0.4 parts of cobalt with a particle size of 0.4 μm, 0.2 parts of rhodium with a particle size of 0.5 μm, and 0.7 parts of carbonyl nickel powder with a particle size of 0.5 μm , 0.5 parts of vanadium carbide with a particle size of 0.3 μm, 14 parts of tantalum carbide with a particle size of 0.5 μm, 0.7 parts of niobium carbide with a particle size of 0.6 μm, 3 parts of titanium carbide with a particle size of 0.4 μm, and a particle size of 0.2 μm 0.4 parts of hafnium carbide, 0.3 parts of aluminum nitride with a particle size of 0.4 μm, and 82 parts of tungsten carbide with a particle size of 0.3 μm.

[0061] Preparation:

[0062] S1: Take all the raw materials according to the specified mass parts, mix them evenly, add ball milling medium and place it in a ball mill for ball milling....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com