Aluminum-titanium-boron alloy and preparation method thereof

A technology of aluminum-titanium-boron and alloy, which is applied in the field of aluminum-titanium-boron alloy and its preparation, can solve the problems of difficult control of reaction temperature, reduction of the amount of particle raw materials added, and high price of raw materials, so as to reduce processing energy consumption and production cost, Avoid intermediate recycling process, the effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the aluminum-titanium-boron alloy provided by the present invention, compared with the preparation of the aluminum-titanium-boron alloy by the fluorine salt method of potassium fluoroborate and potassium fluorotitanate, can greatly reduce the addition of fluorine salt by using titanium chips instead of potassium fluorotitanate The amount of fluoride in the preparation process is significantly reduced, reducing pollution, and the obtained alloy is relatively pure, and the quality is relatively improved; The advantage of reducing the amount of fluorine salt particles added is that the prepared Al-Ti-B alloy is relatively pure; compared with the Al-Ti-B alloy prepared by self-propagating high-temperature synthesis method, the preparation process is simple, the source of raw materials is wide and the price is cheap.

[0026] Therefore, in the present invention, by melting the titanium chips together with the mixture of potassium fluoroborate and sod...

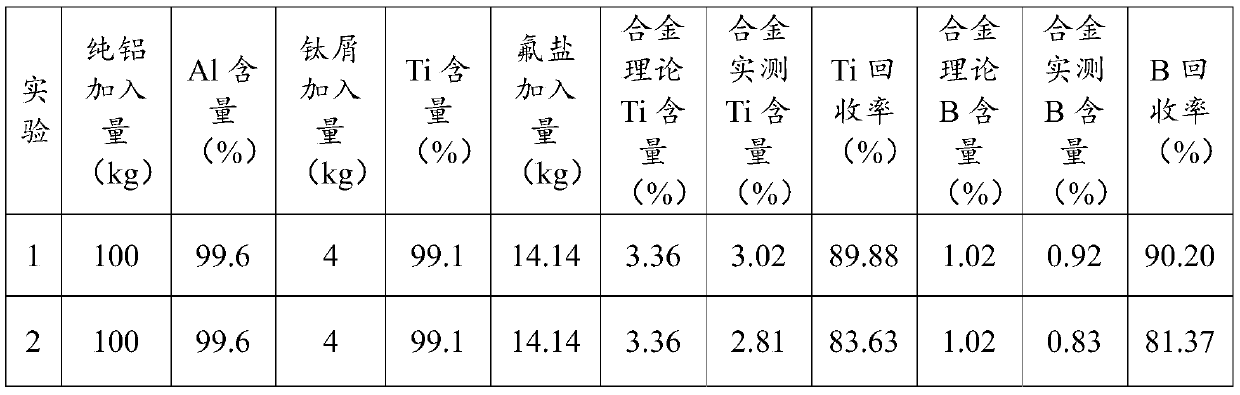

Embodiment 1

[0044] This embodiment is a method for preparing an aluminum-titanium-boron alloy. The method is to prepare an Al-5%Ti-1%B alloy by using a mixture of aluminum, titanium chips, potassium fluoroborate and sodium fluoride. The specific steps are as follows:

[0045] Firstly, the titanium chips produced by machining (pure titanium chips containing only titanium elements) are crushed on a crusher, and after the titanium chips are crushed into a flake structure with a maximum size of less than 5mm, the dirt on the surface of the titanium chips is removed with an organic solvent-ethanol. Remove, weigh 6kg of titanium scraps after drying and pack the titanium scraps into bags with 0.1mm thick aluminum foil, each bag contains 0.5kg of titanium scraps;

[0046] Weigh 12kg of potassium fluoroborate and 0.12kg of sodium fluoride, dry them at 80°C for 30 minutes, mix them evenly, and pack them into bags with 0.1mm thick aluminum foil, 0.505kg per bag;

[0047] After melting 100kg of pure ...

Embodiment 2

[0055] The present embodiment is a method for preparing an aluminum-titanium-boron alloy. The method is to prepare an Al-3%Ti-1%B alloy by using a mixture of aluminum, titanium chips, potassium fluoroborate and sodium fluoride. The specific steps are as follows:

[0056] Firstly, the titanium chips produced by machining (pure titanium chips containing only titanium elements) are crushed on a crusher, and after the titanium chips are crushed into a flake structure with a maximum size of less than 5mm, the dirt on the surface of the titanium chips is removed with an organic solvent-ethanol. Remove, weigh 4kg of titanium scraps after drying and pack them into bags with 0.05mm thick aluminum foil, each bag contains 0.4kg of titanium scraps;

[0057] Weigh 14kg of potassium fluoroborate and 0.14kg of sodium fluoride, dry them at 80°C for 30 minutes, mix them evenly, and pack them into bags with 0.05mm aluminum foil, 0.505kg per bag;

[0058] After melting 100kg of pure aluminum in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com