Energy-saving, heat-preserving and low-emissivity glass for light buildings and its preparation method

A low-emissivity glass, building energy-saving technology, applied in the field of low-emissivity glass, can solve problems such as shortening the life of the coating layer, and achieve the effect of enhancing anti-oxidation performance, ensuring mechanical properties, and refining Ag crystal grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

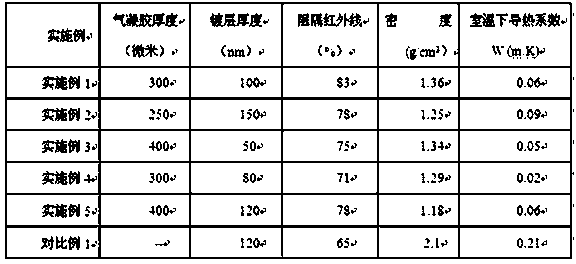

Examples

Embodiment 1

[0029] A method for preparing energy-saving, heat-preserving and low-emissivity glass for light buildings, comprising the following steps:

[0030] Pass the water glass through a cation exchange resin to obtain an acidic silicic acid solution, adjust the pH value of the acidic silica sol to 8.3, then stir at room temperature for 50 min, then adjust the pH of the alkaline silica sol to 5.3 to obtain Silica sol, then adding triethylamine to the silica sol, then pouring it into a mold with polyimide foam fiber reinforcement to carry out gelation at room temperature, and then aging at 120°C to obtain two Silica wet gel, drying the silica wet gel to obtain silica aerogel;

[0031] The silicon dioxide is gas-condensed to form a thin film, placed in a vacuum deposition chamber, and then the vacuum deposition chamber is evacuated to 10 - 3Pa, with a composite target of silver, copper and nickel, and then pass argon into the vacuum deposition chamber until the pressure is 2Pa, the fl...

Embodiment 2

[0034] A method for preparing energy-saving, heat-preserving and low-emissivity glass for light buildings, comprising the following steps:

[0035] Pass water glass through a cation exchange resin to obtain an acidic silicic acid solution, adjust the pH value of the acidic silica sol to 7.5, then stir at room temperature for 45 minutes, then adjust the pH of the alkaline silica sol to 4.5 to obtain Silica sol, then add potassium hydroxide to the silica sol, then pour it into a mold with polyurethane foam fiber reinforcement to carry out standing gel at room temperature, and then age at 100°C to obtain silica wet Gel, drying the silica wet gel to obtain silica aerogel;

[0036] The silicon dioxide is gas-condensed to form a thin film, placed in a vacuum deposition chamber, and then the vacuum deposition chamber is evacuated to 10 - 3 Pa, with a composite target of silver, copper and nickel, argon gas is introduced into the vacuum deposition chamber until the pressure is 3Pa, ...

Embodiment 3

[0039] A method for preparing energy-saving, heat-preserving and low-emissivity glass for light buildings, comprising the following steps:

[0040] Pass water glass through a cation exchange resin to obtain an acidic silicic acid solution, adjust the pH value of the acidic silica sol to 8.0, then stir at room temperature for 45 minutes, then adjust the pH of the alkaline silica sol to 4.9 to obtain Silica sol, then add ammonia water to the silica sol, then inject it into a mold with glass wool felt fiber reinforcement to carry out standing gel at room temperature, and then age at 120°C to obtain silica wet coagulation gel, drying the silica wet gel to obtain silica aerogel;

[0041] The silicon dioxide is gas-condensed to form a thin film, placed in a vacuum deposition chamber, and then the vacuum deposition chamber is evacuated to 10 - 3 Pa, with a composite target of silver, copper and platinum, argon is introduced into the vacuum deposition chamber until the pressure is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com