A Microgravity Solidification Device for Metal Droplets

A metal droplet, microgravity technology, applied in the investigation phase/state change and other directions, can solve the problems of restricting scientific research and technological application development, increasing the cost of experimental equipment and experimental time, etc., to eliminate tissue inhomogeneity, eliminate macroscopic The effect of segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

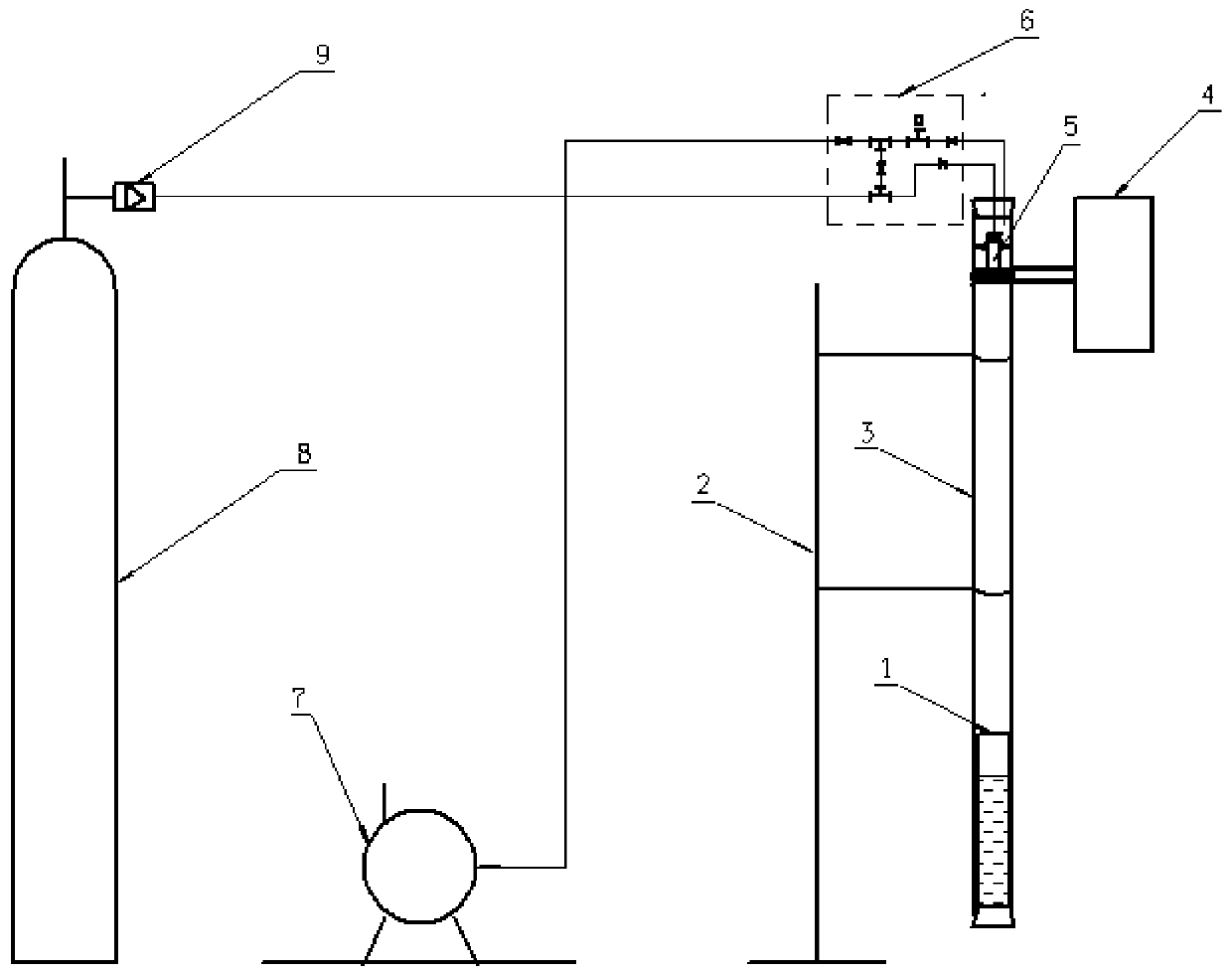

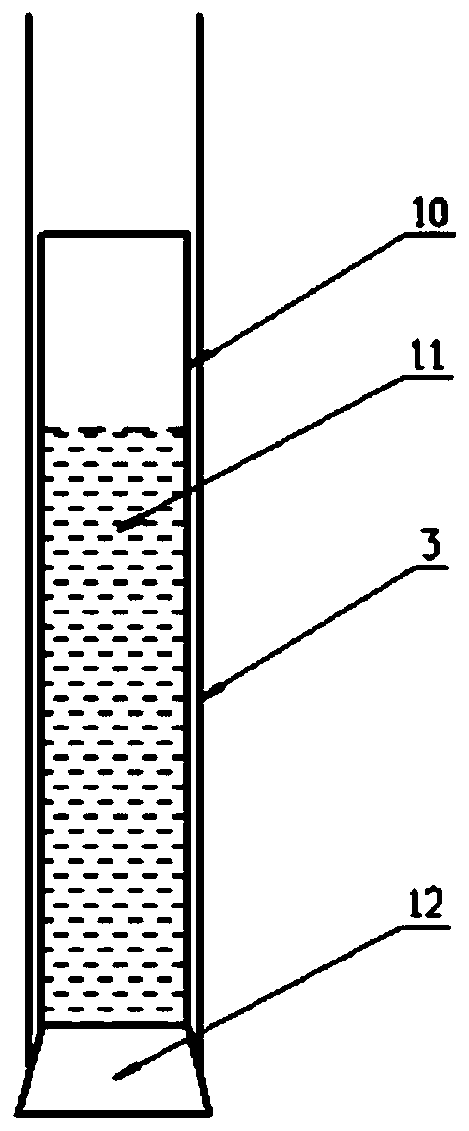

[0027] This embodiment is a microgravity solidification device for metal droplets, including: a liquid quenching collector 1, a support frame 2, a pipe body 3, a high-frequency induction heater 4, a sample installation section 5, a gas circuit control terminal 6, and a vacuum pump 7. Experimental atmosphere source 8 and gas flow controller 9. Wherein: the tube body 3 is fixed on the support frame 2; the upper end of the tube body 3 is a sample installation section 5, and the liquid quenching collector 1 is placed in the tube at the lower end. A sample 15 is placed at the bottom of a test tube 16 located in the sample mounting section. A heating coil 13 is sleeved on the tube body 3, and the heating coil is located at the lower end of the test tube 16, so that the sample is located in the middle of the heating coil axial height; the heating coil and the high-frequency induction heater 4 connect. The test tube communicates with the experimental atmosphere source 8 through a ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com