Preparation method of iron-nickel-molybdenum metal magnetic powder core with magnetic permeability mu = 400

A technology of iron-nickel-molybdenum and magnetic permeability, which is applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problems of brittle magnetic core performance, low molding pressure, high pressure, etc., and achieve low molding pressure , reduce the molding pressure, increase the effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

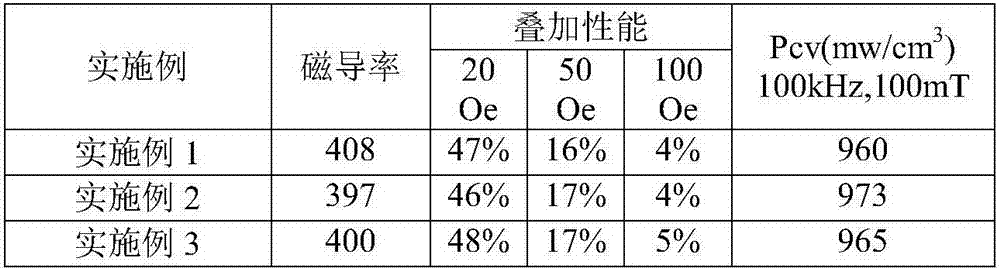

Embodiment 1

[0036] A preparation method of an iron-nickel-molybdenum metal magnetic powder core with a magnetic permeability μ=400, comprising the following steps:

[0037] (1) weighing: according to 80% nickel ingot, 2.8% ferromolybdenum (molybdenum content 55%, surplus is iron), surplus is the mass percentage content proportioning of iron and takes each component, for subsequent use;

[0038] (2) Gas atomization pulverization: each component is melted in an intermediate frequency induction furnace, and atomized pulverization is carried out by nitrogen at a pressure of 1.2 MPa through the tundish of the atomization equipment;

[0039] (3) Particle size combination: After sieving the magnetic powder obtained in step (2) according to the particle size, the particle size combination is carried out according to different particle size ratios. Based on the total mass of the magnetic powder matrix, the magnetic powder particle size combination is: -140~+200 mesh magnetic powder 5%, -200~+300 m...

Embodiment 2

[0047] A preparation method of an iron-nickel-molybdenum metal magnetic powder core with a magnetic permeability μ=400, comprising the following steps:

[0048] (1) weighing: according to 82% nickel ingot, 3.2% ferromolybdenum (molybdenum content 65%, surplus is iron), surplus is the mass percentage content ratio of iron and takes each component, for subsequent use;

[0049] (2) Gas atomization pulverization: each component is melted in an intermediate frequency induction furnace, and atomized pulverization is carried out by nitrogen at a pressure of 3.2 MPa through the tundish of the atomization equipment;

[0050] (3) Particle size combination: After sieving the magnetic powder obtained in step (2) according to the particle size, the particle size combination is carried out according to different particle size ratios. Based on the total mass of the magnetic powder matrix, the magnetic powder particle size combination is: -140~+200 mesh magnetic powder 15%, -200~+300 mesh mag...

Embodiment 3

[0059] A preparation method of an iron-nickel-molybdenum metal magnetic powder core with a magnetic permeability of 400, comprising the following steps:

[0060] (1) Weighing: according to 81% nickel ingot, 3.0% ferromolybdenum (molybdenum content 60%, surplus is iron), surplus is the mass percentage content proportioning of iron and takes each component, for subsequent use;

[0061] (2) Gas atomization pulverization: each component is melted in an intermediate frequency induction furnace, and atomized pulverization is carried out by nitrogen at a pressure of 2.4 MPa through the tundish of the atomization equipment;

[0062] (3) Particle size combination: After sieving the magnetic powder obtained in step (2) according to the particle size, the particle size combination is carried out according to different particle size ratios. Based on the total mass of the magnetic powder matrix, the magnetic powder particle size combination is: -140~+200 mesh magnetic powder 10%, -200~+300...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com