Steel slag-fiber composite rubber packing with phase change temperature control performance and preparation method of steel slag-fiber composite rubber packing

A fiber composite and rubber filler technology, which is applied in the direction of artificial filaments made of cellulose derivatives, heat exchange materials, fiber chemical characteristics, etc., can solve the problem of high price of filler carbon black and white carbon black, phase change temperature regulation The effect is limited, and the rubber is prone to agglomeration, etc., to achieve the effect of enriching functionality, improving reinforcement, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0033] Phase change tempering steel slag 60g;

[0034] 40g of phase-change temperature-regulating fiber;

[0035] The particle size of the phase-change temperature-adjusted steel slag is 4.70 μm to 90.29 μm, and its composition is as follows in terms of mass percentage:

[0036] Phosphoric acid solution 2%;

[0037] Steel slag 50%;

[0038] Phase change materials 48%;

[0039] The mass fraction of the phosphoric acid solution is 65%; the steel slag is molten iron desulfurization slag, and its chemical composition (mass fraction) is SiO 2 (15.32%), Fe 2 o 3 (12.64%), Al 2 o 3 (5.47%), CaO (51.34%), MgO (3.47%), P 2 o 5 (0.50%), MnO (0.80%), SO 3 (2.06%) and others (8.40%); the phase change material is paraffin.

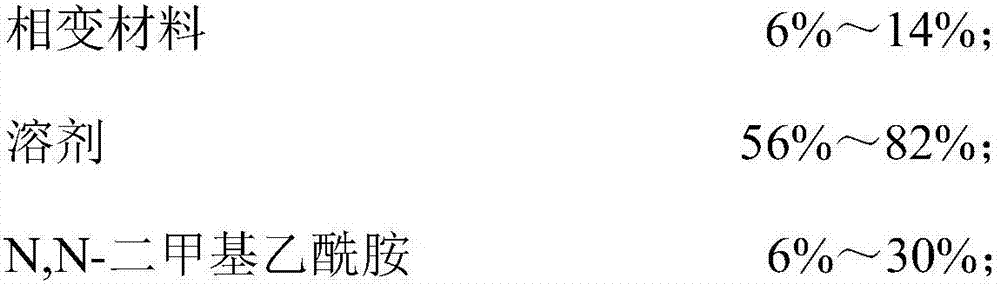

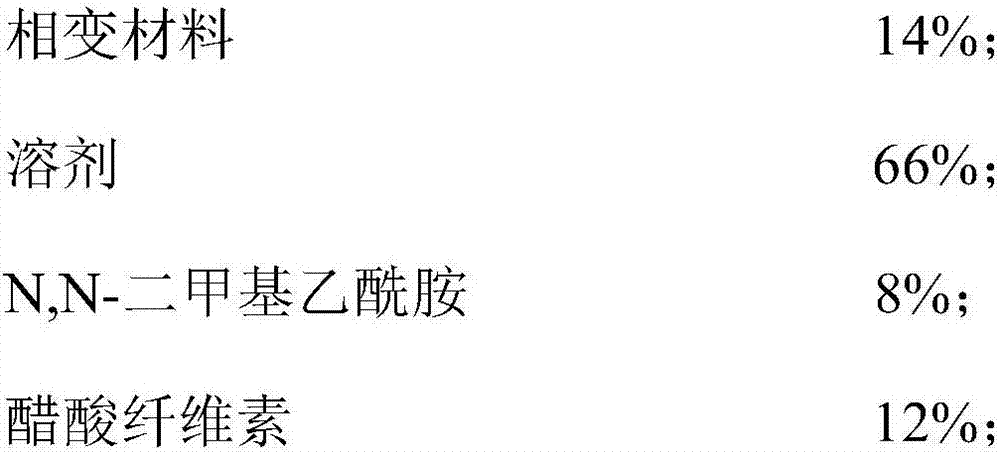

[0040] The long diameter of the phase-change temperature-regulating fiber is 62-196, and its composition is as follow...

Embodiment 2

[0047] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0048] Phase change tempering steel slag 80g;

[0049] 20g phase-change temperature-regulating fiber;

[0050] The particle size of the phase-change temperature-adjusted steel slag is 5.04 μm to 105.30 μm, and its composition is as follows in terms of mass percentage:

[0051] Phosphoric acid solution 5%;

[0052] Steel slag 55%;

[0053] Phase change materials 40%;

[0054] The mass fraction of the phosphoric acid solution is 85%; the steel slag is casting residue, and its chemical composition (mass fraction) is SiO 2 (10.0%~18.0%), Fe 2 o 3 (10.0%~35.0%), Al 2 o 3 (2.0%~12.0%), CaO(35.0%~55.0%), MgO(3.0%~7.0%), P 2 o 5 (0.5%~1.0%), MnO(0.5%~4.0%), SO 3 (0.1%~3.0%) and others (4.0%~9.0%); the phase change material is palmitic alcohol-palmitic acid-lauric acid, and the mass fraction ratio of palmitic alcohol, palmitic acid and l...

Embodiment 3

[0062] Taking the preparation of product 100g of the present invention as an example, the components used and their mass proportions are:

[0063] Phase change tempering steel slag 70g;

[0064] 30g phase-change temperature-regulating fiber;

[0065] The particle size of the phase-change temperature-adjusted steel slag is 5.48 μm to 104.30 μm, and its composition is as follows in terms of mass percentage:

[0066] Phosphoric acid solution 3%;

[0067] Steel slag 53%;

[0068] Phase change materials 44%;

[0069] The mass fraction of the phosphoric acid solution is 75%; the steel slag is converter hot slag, and its chemical composition (mass fraction) is SiO 2 (11.06%), Fe 2 o 3 (24.40%), Al 2 o 3 (2.30%), CaO (46.78%), MgO (5.75%), P 2 o 5 (0.91%), MnO (2.19%), SO 3 (0.23%) and others (6.38%); the phase change material is capric acid-palmitic acid, and the mass fraction ratio of capric acid and palmitic acid is 85.5:14.5.

[0070] The long diameter of the phase-cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com