Zirconia single crystal optical fiber and its preparation method and application

A technology of zirconia and optical fiber, applied in chemical instruments and methods, cladding optical fiber, single crystal growth, etc., can solve problems such as inability to perform high temperature measurement, and achieve high hardness, high crystal quality, and high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

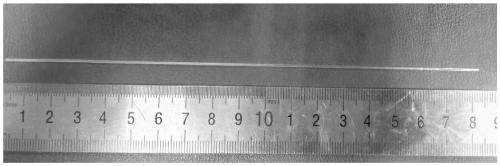

[0047] ZrO 2 The preparation method of single crystal fiber is as follows:

[0048] (1) Selection and treatment of source rod and seed crystal

[0049] ZrO 2 The polycrystalline material was cut into two kinds of square rods of 1×1×150mm and 1×1×20mm respectively as raw materials and seed crystals, which were fixed on the Al with grooves with high-temperature ceramic glue. 2 o 3 Dry on rods at 65°C for 4 hours.

[0050] (2) Crystal growth

[0051] a Clean the furnace cavity and laser mirror, fix the prepared raw material on the feeding device, and fix the prepared seed crystal on the upper pulling device. Increase the laser power to 100W to melt the material rod, adjust the center of the material rod to be at the laser reflection focus, continue to increase the power to 140W to form a stable hemispherical melting zone, and keep the temperature for 10 minutes.

[0052] b Lower the seed crystal to make it contact with the melting zone, adjust the position of the seed crystal...

Embodiment 2

[0056] ZrO 2 The preparation method of single crystal fiber is as follows:

[0057] (1) Selection and treatment of source rod and seed crystal

[0058] ZrO 2 The polycrystalline material was cut into two kinds of square rods of 1×1×150mm and 1×1×20mm respectively as raw materials and seed crystals, which were fixed on the Al with grooves with high-temperature ceramic glue. 2 o 3 Dry on rods at 65°C for 4 hours.

[0059] (2) Crystal growth

[0060] a Clean the furnace cavity and laser mirror, fix the prepared raw material on the feeding device, and fix the prepared seed crystal on the upper pulling device. Increase the laser power to 100W to melt the material rod, adjust the center of the material rod to be at the laser reflection focus, continue to increase the power to 140W to form a stable hemispherical melting zone, and keep the temperature for 10 minutes.

[0061] b Lower the seed crystal to make it contact with the melting zone, adjust the position of the seed cryst...

Embodiment 3

[0065] ZrO 2 The preparation method of single crystal fiber is as follows:

[0066] (1) Selection and treatment of source rod and seed crystal

[0067] ZrO 2 The polycrystalline material was cut into two kinds of square rods of 1×1×150mm and 1×1×20mm respectively as raw materials and seed crystals, which were fixed on the Al with grooves with high-temperature ceramic glue. 2 o 3 Dry on rods at 80°C for 4 hours.

[0068] (2) Crystal growth

[0069] a Clean the furnace cavity and laser mirror, fix the prepared raw material on the feeding device, and fix the prepared seed crystal on the upper pulling device. Increase the laser power to 100W to melt the material rod, adjust the center of the material rod to be at the laser reflection focus, continue to increase the power to 140W to form a stable hemispherical melting zone, and keep the temperature for 10 minutes.

[0070] b Lower the seed crystal to make it contact with the melting zone, adjust the position of the seed cryst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com