An automatic rolling ball forming device

A technology of rolling into balls and ball-forming machines, which is applied to supply devices, ceramic molding machines, manufacturing tools, etc., can solve the problems of low production efficiency, large quality fluctuations, time-consuming and labor-intensive, and achieve stable product quality. Workers' labor intensity and the effect of small fluctuation of ball diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In the following, the specific implementation manners of the present invention will be further described in detail in conjunction with the accompanying drawings of the embodiments, so as to make the technical solution of the present invention easier to understand and grasp.

[0011] The invention breaks through the limitation of traditional technology, and innovatively proposes an automatic rolling ball forming device, which solves the problem of automatic production of ceramic microparticles and can greatly reduce the labor intensity of workers.

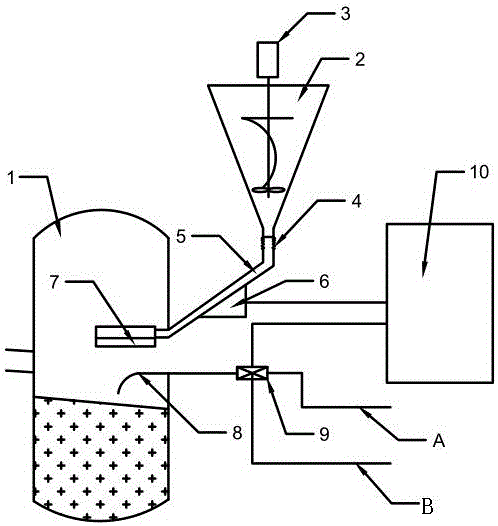

[0012] Such as figure 1 As shown, this kind of automatic rolling into ball device consists of rolling into ball machine 1, powder bin 2, stirring unit 3, soft joint 4, feeding pipe 5, electromagnetic vibration feeding unit 6, sieve 7, air atomization unit , solenoid valve 9 and electric control cabinet 10 and other components. From the point of view of the detailed structure, the powder silo 2 is filled with ceramic powder r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com