Method for preparing glass ceramics by utilizing waste rare-earth polishing powder

A rare earth polishing powder and glass ceramic technology, which is applied in glass molding, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of effective treatment of lead-free tailings, achieve harmless utilization, shorten the preparation process, Good acid and alkali resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

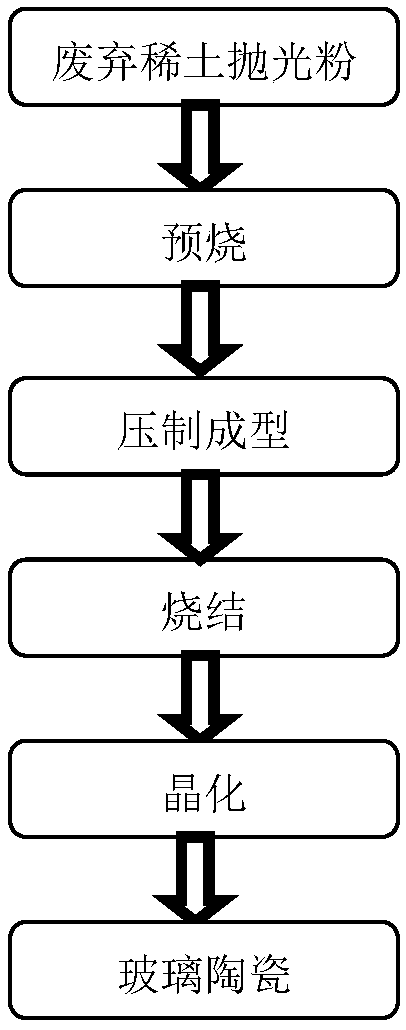

[0030] A method for preparing glass ceramics by using waste rare earth polishing powder, comprising the following steps:

[0031] (1) Weigh 30.006g of waste rare earth polishing powder and put it into a mold, place it in a high-temperature furnace, and pre-burn it at 400°C for 20 minutes;

[0032] (2) Pack the waste rare earth polishing powder after pre-burning into the mould, and use a molding pressure of 1000N to compact the waste rare earth polishing powder;

[0033] (3) Put the compressed rare earth polishing powder into the mold, put it into a high-temperature furnace, and heat it at 5°C min -1 The heating rate was raised to 650°C, and sintered at a constant temperature for 30 minutes;

[0034] (4) Then at 5°C·min -1 The heating rate was raised to 800°C, crystallized at a constant temperature for 30 minutes, and finally air-cooled to room temperature to make a glass ceramic sample.

[0035] The main components of waste rare earth polishing powder are: CeO 2 Ingredient...

Embodiment 2

[0038] A method for preparing glass ceramics by using waste rare earth polishing powder, comprising the following steps:

[0039] (1) Weigh 30.012g of waste rare earth polishing powder and put it into a mold, place it in a high-temperature furnace, and pre-fire it at 500°C for 90min;

[0040] (2) Pack the waste rare earth polishing powder after pre-burning into the mould, and use a molding pressure of 4000N to compact the waste rare earth polishing powder;

[0041] (3) Put the compressed rare earth polishing powder into the mold, put it into a high-temperature furnace, and heat it at 5°C min -1 The heating rate was raised to 750°C, and sintered at a constant temperature for 200 minutes;

[0042] (4) Then at 5°C·min -1 The heating rate was raised to 900°C, crystallized at a constant temperature for 200 minutes, and finally air-cooled to room temperature to make a glass ceramic sample.

[0043] The main components of waste rare earth polishing powder are: CeO 2 Ingredient 2%...

Embodiment 3

[0046] A method for preparing glass ceramics by using waste rare earth polishing powder, comprising the following steps:

[0047] (1) Weigh 30.009g of waste rare earth polishing powder and put it into a mold, place it in a high-temperature furnace, and pre-fire it at 450°C for 70min;

[0048] (2) Pack the waste rare earth polishing powder after pre-burning into the mould, and use a molding pressure of 2500N to compact the waste rare earth polishing powder;

[0049] (3) Put the compressed rare earth polishing powder into the mold, put it into a high-temperature furnace, and heat it at 10°C min -1 The heating rate was raised to 700°C, and sintered at a constant temperature for 120 minutes;

[0050] (4) Then at 10°C·min -1 The heating rate was raised to 850°C, crystallized at a constant temperature for 120 minutes, and finally air-cooled to room temperature to make a glass ceramic sample.

[0051] The main components of waste rare earth polishing powder are: CeO 2 Composition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com