Polylactide fibrous membrane coated with glucan-g-poly(L-lysine)-VAPG/nucleic acid compound and preparation method

A technology of polylactide and -VAPG, which is applied in the field of tissue engineering and gene therapy, can solve problems such as prolongation, achieve the effects of slowing down the burst release, simple and easy preparation process, and protecting biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

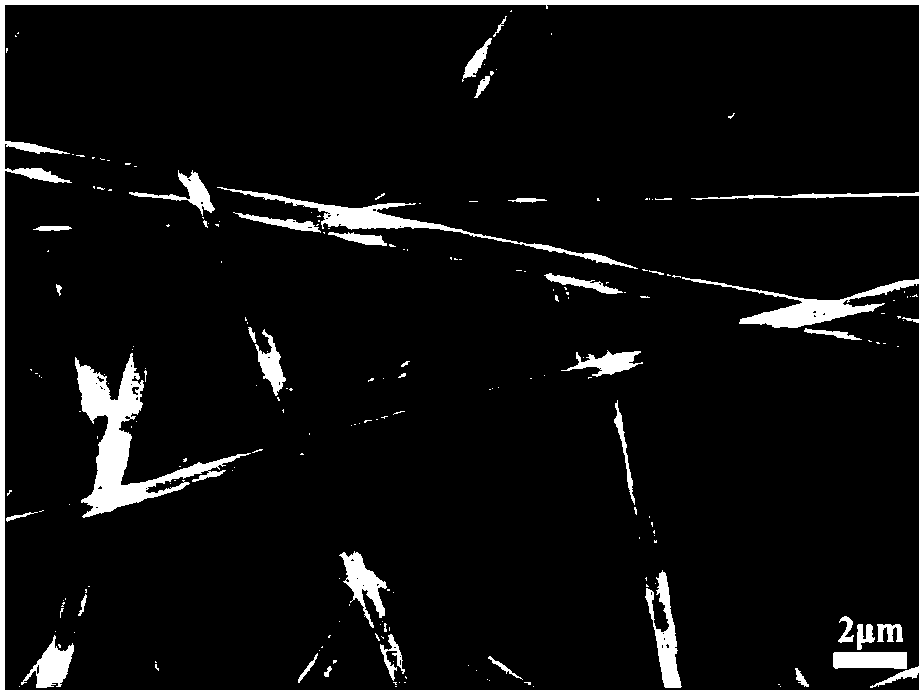

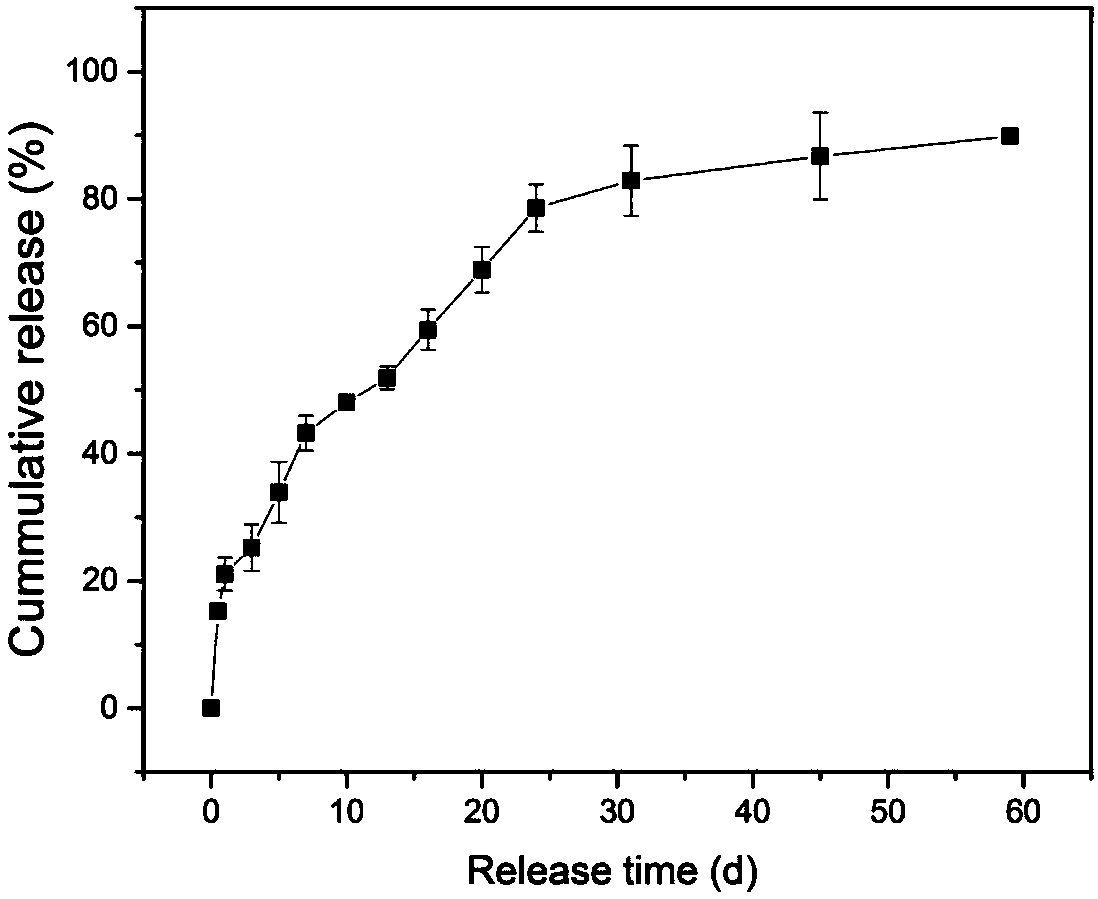

Image

Examples

Embodiment 1

[0026] (1) Weigh the weight average molecular weight to be 1×10 5 400 mg of PLGA (lactide: glycolide = 3:1) was dissolved in 4 mL of a mixed solvent of chloroform and N,N'-dimethylformamide with a volume ratio of 4:1, and 48 mg of F127 was added as an emulsified agent, stirred overnight at room temperature to obtain a homogeneous oily solution (O).

[0027](2) Weigh the weight average molecular weight to be 3.6×10 4 Dextran-g-poly( L -lysine)-VAPG polymer 10mg, dissolved in 2mL of DEPC water; 25μL of DEPC water was added to 1OD miRNA to prepare a miRNA solution with a concentration of 1.32mg / mL; according to the polymer / miRNA ratio of 2:1 For mass ratio, 60 μL of miRNA solution was mixed with 32 μL of polymer solution at room temperature for 15-45 min, and 68 μL of TE buffer was added to form a uniform aqueous phase solution (W).

[0028] (3) According to the water-to-oil ratio of 1:25, stir and mix 4 mL of the oil phase solution with the above 160 μL of the water phase sol...

Embodiment 2

[0030] (1) Weigh the weight average molecular weight to be 7.5×10 4 800 mg of PLGA (lactide: glycolide = 3:1) was dissolved in 4 mL of a mixed solvent of chloroform and N,N'dimethylformamide with a volume ratio of 6:1, and 44 mg of F127 was added as an emulsifier , stirring overnight at room temperature to obtain a homogeneous oily solution (O).

[0031] (2) Weigh the weight average molecular weight to be 2.1×10 4 Dextran-g-poly( L -Lysine)-VAPG polymer 10 mg, dissolved in 2 mL of DEPC water; add 25 μL of DEPC water to 1OD miRNA to prepare a miRNA solution with a concentration of 1.32 mg / mL, and follow the polymer / miRNA ratio of 3:1 60 μL of miRNA solution was mixed with 48 μL of polymer solution at room temperature for 15-45 min at room temperature, and 52 μL of TE buffer was added to form a uniform aqueous phase solution (W).

[0032] (3) According to the water-to-oil ratio of 1:25, stir and mix 4 mL of the oil phase solution with the above 160 μL of the water phase solut...

Embodiment 3

[0034] (1) Weigh the weight average molecular weight to be 5×10 4 1200mg of PLGA (lactide: glycolide = 3:1) was dissolved in 4mL of a mixed solvent of chloroform and N,N'dimethylformamide with a volume ratio of 8:1, and 40mg of F127 was added as an emulsifier , stirring overnight at room temperature to obtain a homogeneous oily solution (O).

[0035] (2) Weigh the weight average molecular weight to be 1.5×10 4 Dextran-g-poly( L -Lysine)-VAPG polymer 10 mg, dissolved in 2 mL of DEPC water; add 25 μL of DEPC water to 1OD miRNA to prepare a miRNA solution with a concentration of 1.32 mg / mL, and follow the polymer / miRNA ratio of 4:1 45 μL of miRNA solution was mixed with 48 μL of polymer solution at room temperature for 15-45 min, and 107 μL of TE buffer was added to form a uniform aqueous solution (W).

[0036] (3) According to the water-to-oil ratio of 1:20, stir and mix 4 mL of the oil phase solution with the above 200 μL of the water phase solution for 0.5-2 hours to form a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com