Lightweight sound-absorption heat-insulation polyimide foamed material, and preparation method thereof

A technology of polyimide and foam materials, which is applied in the field of light-weight sound-absorbing and heat-insulating polyimide foam materials and its preparation, can solve the problems of unsatisfactory dimensional stability, increased cell pressure difference, and The wall strength is weak and other problems, and the foaming process is simple and easy to control, the performance is stable, and the effect of sound absorption and heat insulation is strong.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

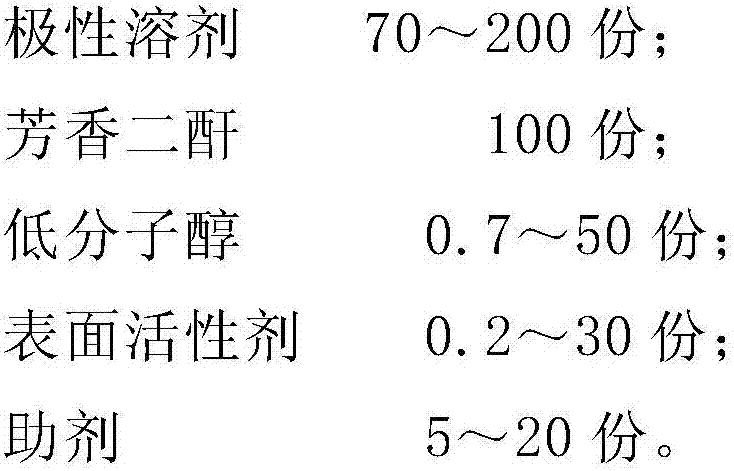

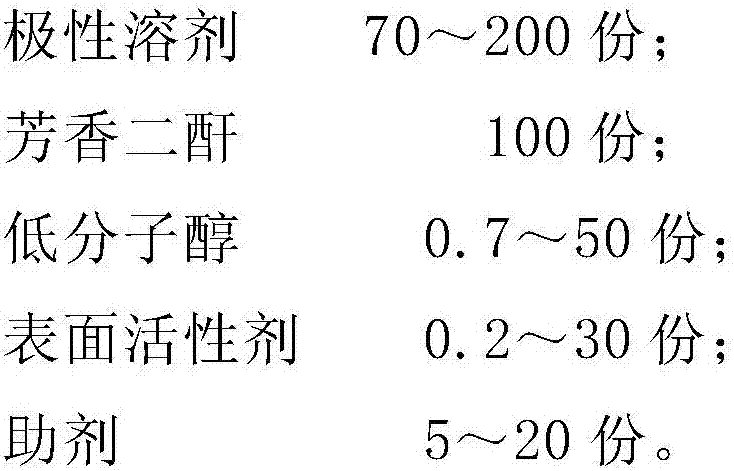

Method used

Image

Examples

Embodiment 1

[0043] Take a 500ml four-neck flask, add 200g of dimethylformamide, 16g of anhydrous methanol, 6g of PEG600, and 10g of simethicone, stir well, raise the temperature to 70°C, add 100g of pyromellitic dianhydride, and wait until the solution After being transparent, the temperature was lowered to below 40° C., and then 8 grams of deionized water was added and stirred for 30 minutes to obtain a brownish yellow transparent precursor solution.

[0044] Weigh 50 grams of the above precursor solution, add 36 grams of 4,4'-diphenylmethane diisocyanate, stir rapidly for 10 seconds, pour it into the prepared mold, release it after free foaming for 1 minute, and put it in the microwave oven , treated at 40-50°C for 10 minutes to obtain a yellow foam preform, which was placed in an oven, heated to 280°C in vacuum, and maintained for 4 hours to obtain the polyimide foam of the present invention.

[0045] The basic performance parameters of the foam prepared by Test Example 1 are as follow...

Embodiment 2

[0048] Take a 500ml four-necked flask, add 200g of dimethylformamide, 16g of anhydrous methanol, 6g of PEG600, and 10g of simethicone, stir well, raise the temperature to 70°C, add 120g of pyromellitic dianhydride, and wait for the solution After becoming transparent, the temperature was lowered to below 40° C., and then 9 g of deionized water was added and stirred for 30 minutes to obtain a brown-yellow transparent precursor solution.

[0049] Weigh 50 grams of the above precursor solution, add 37 grams of 4,4'-diphenylmethane diisocyanate, stir rapidly for 10 seconds, pour it into the prepared mold, release it after free foaming for 1 minute, and put it in a microwave oven , treated at 40-50°C for 10 minutes to obtain a yellow foam preform, which was placed in an oven, heated to 280°C in vacuum, and maintained for 4 hours to obtain the polyimide foam of the present invention.

[0050] The basic performance parameters of the foam prepared by Test Example 2 are as follows:

...

Embodiment 3

[0053] Take a 500ml four-neck flask, add 200g of dimethylformamide, 16g of anhydrous methanol, 5g of PEG600, and 12g of simethicone, stir well, raise the temperature to 70°C, add 120g of benzophenonetetraacid dianhydride, wait After the solution was transparent, the temperature was lowered to below 40° C., and then 7 g of deionized water was added and stirred for 30 minutes to obtain a light yellow transparent precursor solution.

[0054] Weigh 50 grams of the above precursor solution, add 36 grams of polymethyl polyphenylisocyanate, stir rapidly for 10 seconds, pour it into the prepared mold, release it after free foaming for 1 minute, put it in a microwave oven, 50-60 temperature for 20 minutes to obtain a yellow foam preform, put it in an oven, raise the temperature to 270° C. in vacuum, and maintain it for 6 hours to obtain the polyimide foam of the present invention.

[0055] The basic performance parameters of the foam prepared by Test Example 3 are as follows:

[0056]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com