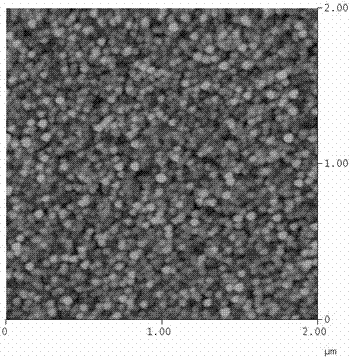

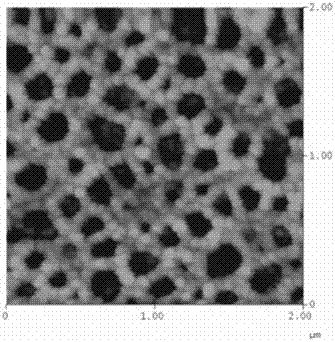

Preparation method of porous CaCu3Ti4O12 film

A technology of calcium copper titanate and porous titanium, which is applied in the preparation of calcium copper titanate thin film materials and the field of preparing porous calcium calcium titanate titanate films, can solve the problem of low density, no obvious special structure in surface morphology, and can not meet the requirements of devices/equipment Light weight and other issues, to achieve the effect of adjustable aperture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] a. Substrate selection and cleaning

[0019] Using heavily doped silicon substrate, the substrate was ultrasonically treated with ethanol and deionized water for 20 minutes, and then placed in a rapid heat treatment device for two-stage annealing: the first stage, the temperature was 200°C for 200s; the second stage, the temperature 200s at 400°C.

[0020] b. Preparation of lanthanum nickelate buffer layer

[0021] Weigh lanthanum nitrate La(NO 3 ) 3 ·6H 2 O solid 3.2 grams, take nickel acetate C according to the ratio of La:Ni atomic molar ratio 1:1 4 h 6 o 4 Ni·4H 2 O solid, add ethanol solvent, stir and heat in a water bath at 40°C for about 3 hours to obtain a homogeneous solution of lanthanum nickelate with a concentration of 0.1mol / L. Let it stand for a period of time, and it can be used without precipitation.

[0022] Place the cleaned silicon substrate in a homogenizer, set the speed at 4000 rpm, and use the above-mentioned lanthanum nickelate solution...

Embodiment 2

[0028] a. Substrate selection and cleaning

[0029] Quartz glass is used as the substrate. The substrate was sonicated with ethanol and deionized water for 20 minutes, and dried with high-purity nitrogen.

[0030] b. Preparation of lanthanum nickelate buffer layer

[0031] Fix the cleaned quartz glass substrate on the sample tray of the pulsed laser deposition system. The deposition chamber is evacuated to 10 -5 Below Pa; Oxygen with a purity of not less than 99.999% is introduced, and the chamber pressure is maintained at 5Pa; the sample tray is heated to 700 o C. Pulse laser ablation of the lanthanum nickelate target material, the laser frequency is 5Hz; after the laser is turned off, the oxygen pressure in the cavity is increased to 100Pa, and the temperature is kept for 30 minutes to obtain a lanthanum nickelate buffer layer with a thickness of about 10 nm.

[0032] c. Configuration of copper calcium titanate precursor solution

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com