Diffusion connection method of ternary layered ceramic carbon silicide and metallic chromium

A ternary layered, diffusion connection technology, applied in the field of ceramic and metal connection, can solve the problems of inability to synthesize large-sized or complex-shaped bulk materials or components, restrictions and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

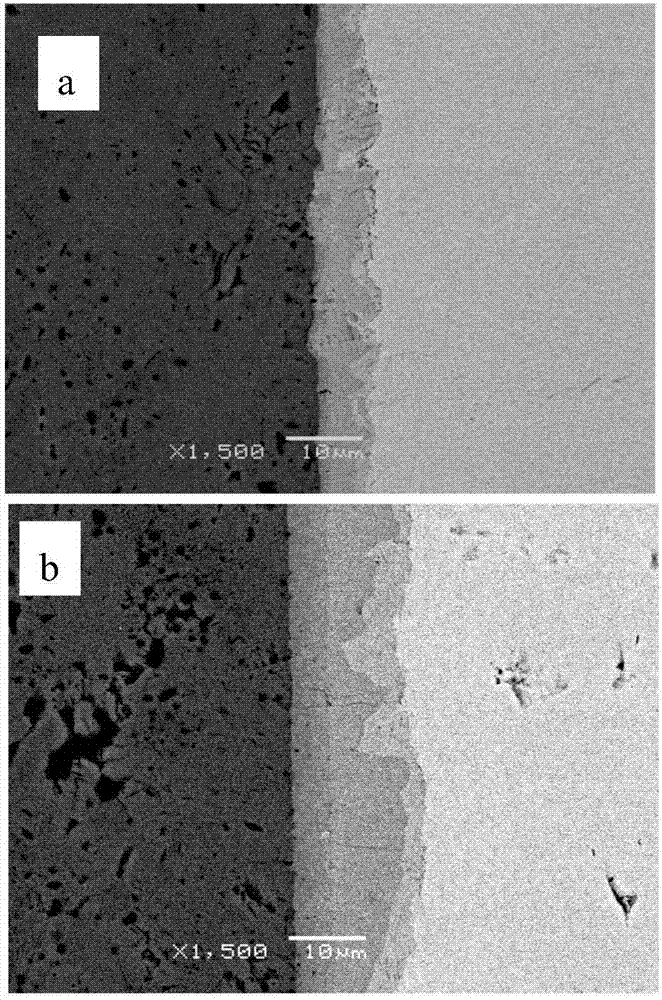

[0014] Embodiment 1: with Ti 3 SiC 2 Ceramic and metallic chrome for surface treatment, Ti 3 SiC 2 Ceramic and metallic chrome are ground, polished, ultrasonically cleaned. Then the processed Ti 3 SiC 2 Ceramic and metal chromium are installed in a hot-pressed furnace and vacuumized; when the vacuum reaches 5 × 10 -2 Heating starts at Pa. At a temperature of 100°C, a pressure of 20 MPa, and constant pressure for 90 minutes, the metal chromium and Ti were diffusely bonded. 3 SiC 2 ceramics. The loading rate is 5MPa / min. After the connection is completed, slowly lower the temperature of the hot-press furnace under the original vacuum condition, first to 400°C at a rate of 5°C / min, and then stop vacuuming and remove the pressure after cooling to 200°C with the furnace. The microscopic morphology of the interface after connection was observed with a scanning electron microscope, and the interface was well connected without pores, cracks or residual welding lines.

Embodiment 2

[0015] Embodiment 2: with Ti 3 SiC 2 Ceramic and metallic chrome for surface treatment, Ti 3 SiC 2 Ceramic and metallic chrome are ground, polished, ultrasonically cleaned. Then the processed Ti 3 SiC 2 Ceramic and metal chromium are installed in a hot-pressed furnace and vacuumized; when the vacuum reaches 5 × 10 -2 Heating starts at Pa. At a temperature of 1100°C, a pressure of 20MPa, and constant pressure for 60 minutes, the metal chromium and Ti were diffusely bonded. 3 SiC 2 ceramics. The loading rate is 5MPa / min. After the connection is completed, slowly lower the temperature of the hot-press furnace under the original vacuum condition, first to 400°C at a rate of 5°C / min, and then stop vacuuming and remove the pressure after cooling to 200°C with the furnace. The microscopic morphology of the interface after connection was observed with a scanning electron microscope, and the interface was well connected without pores, cracks or residual welding lines.

Embodiment 3

[0016] Embodiment 3: with Ti 3 SiC 2 Ceramic and metallic chrome for surface treatment, Ti 3 SiC 2 Ceramic and metallic chrome are ground, polished, ultrasonically cleaned. Then the processed Ti 3 SiC 2 Ceramic and metal chromium are installed in a hot-pressed furnace and vacuumized; when the vacuum reaches 5 × 10 -2 Heating starts at Pa. Diffusion metal chromium and Ti 3 SiC 2 ceramics. The loading rate is 5MPa / min. After the connection is completed, the temperature of the hot-press furnace is slowly lowered under the original vacuum condition, first at a rate of 5°C / min to 400°C, and then the furnace is cooled to 200°C and then the vacuum is stopped and the pressure is withdrawn. The microscopic morphology of the interface after connection was observed with a scanning electron microscope, and the interface was well connected without pores, cracks or residual welding lines. The joint shear strength reaches 121MPa.

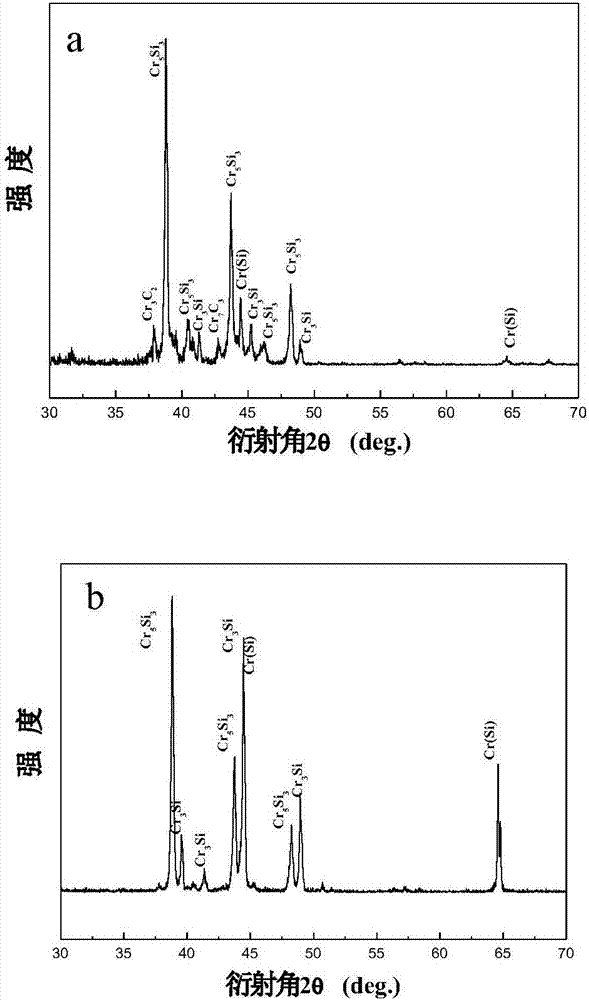

[0017] figure 1 for Ti 3 SiC 2 Interface back...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com