Method of using silicon carbide material, ozone photocatalyst and reactor comprising same

A technology of photocatalytic reactor and photocatalyst, which is applied in the field of waste gas treatment and wastewater, can solve the problems of catalyst instability and low activity, and achieve the effects of low cost, high reactivity and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

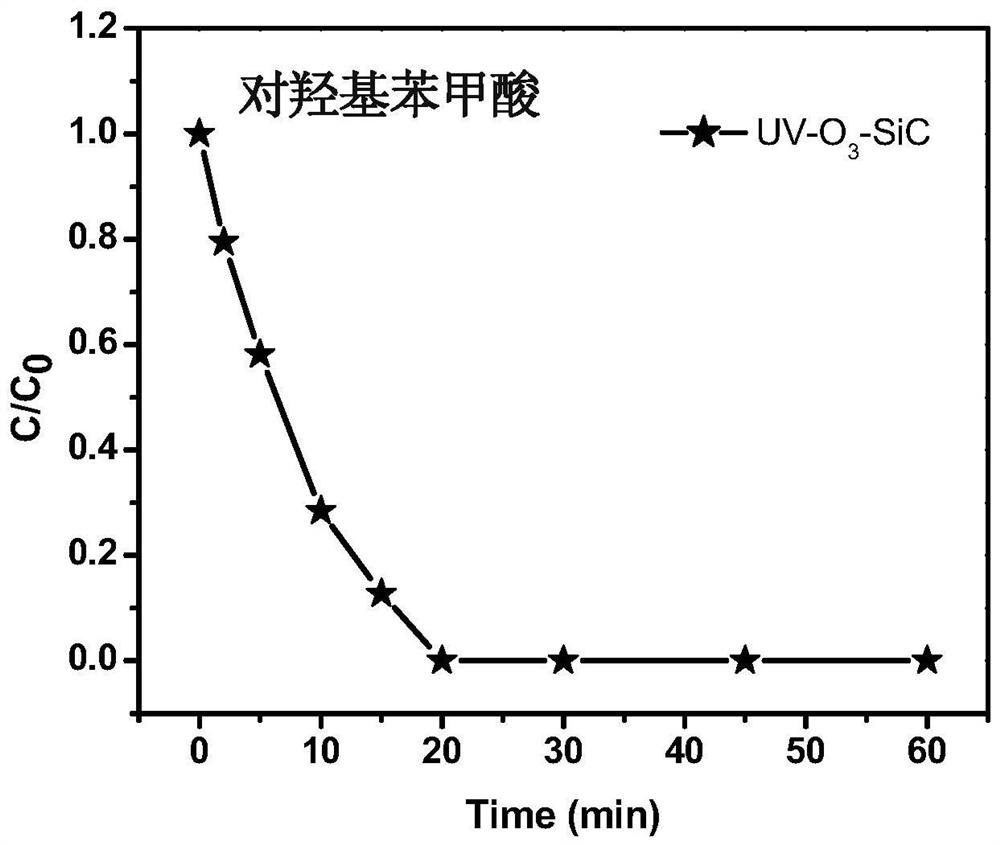

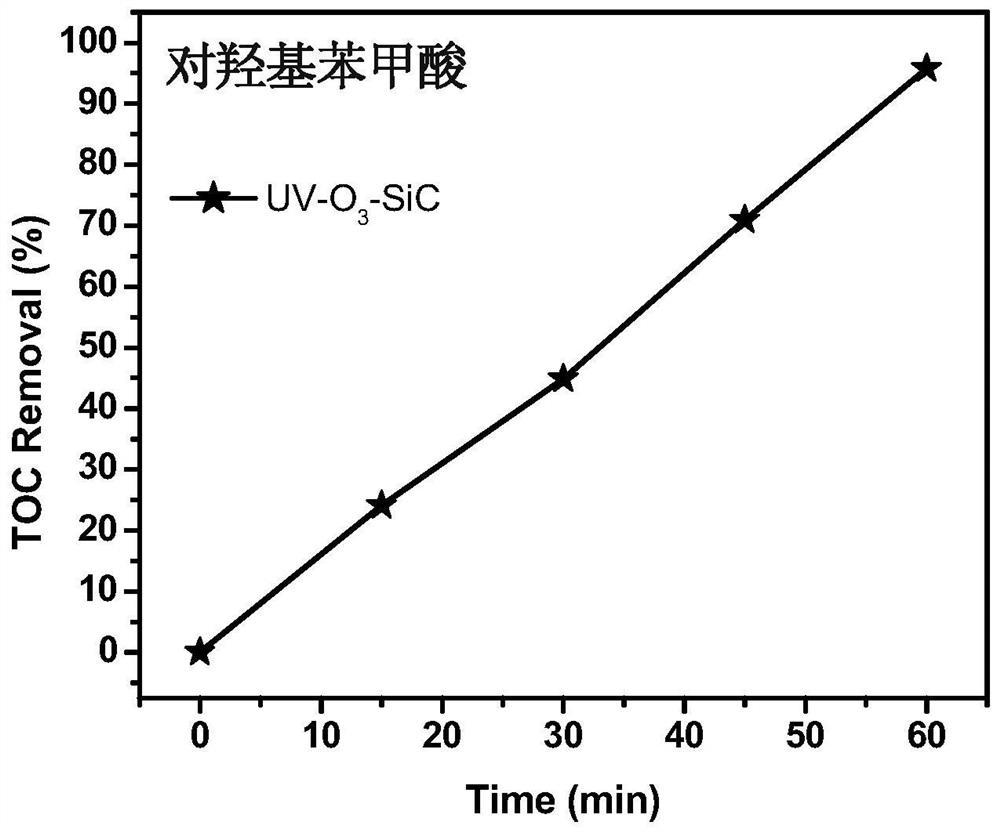

[0051] A method for ozone ultraviolet photocatalytic removal of p-hydroxybenzoic acid in organic wastewater, comprising the steps of:

[0052] In a semi-continuous reactor, 400mL of p-hydroxybenzoic acid with an initial concentration of 40mg / L was used as the reaction solution, and an externally illuminated xenon lamp light source was placed vertically above the reactor, and a filter was used to filter out the visible light region so that the light source only emitted Ultraviolet light, the light wavelength range is 190-400nm, and the light intensity is 160mW / cm 2 ;The flow rate of the ozone gas mixture is 100mL / min, and the ozone concentration is 20mg / L; Weigh 80mg of silicon carbide (catalyst) and put it into the reaction solution, the concentration of silicon carbide is 0.2g / L, and turn on the ultraviolet light source after the solid and liquid are fully mixed. At the same time, the ozone mixture was continuously fed into the reactor; the reaction time was 1 hour, and sampl...

Embodiment 2

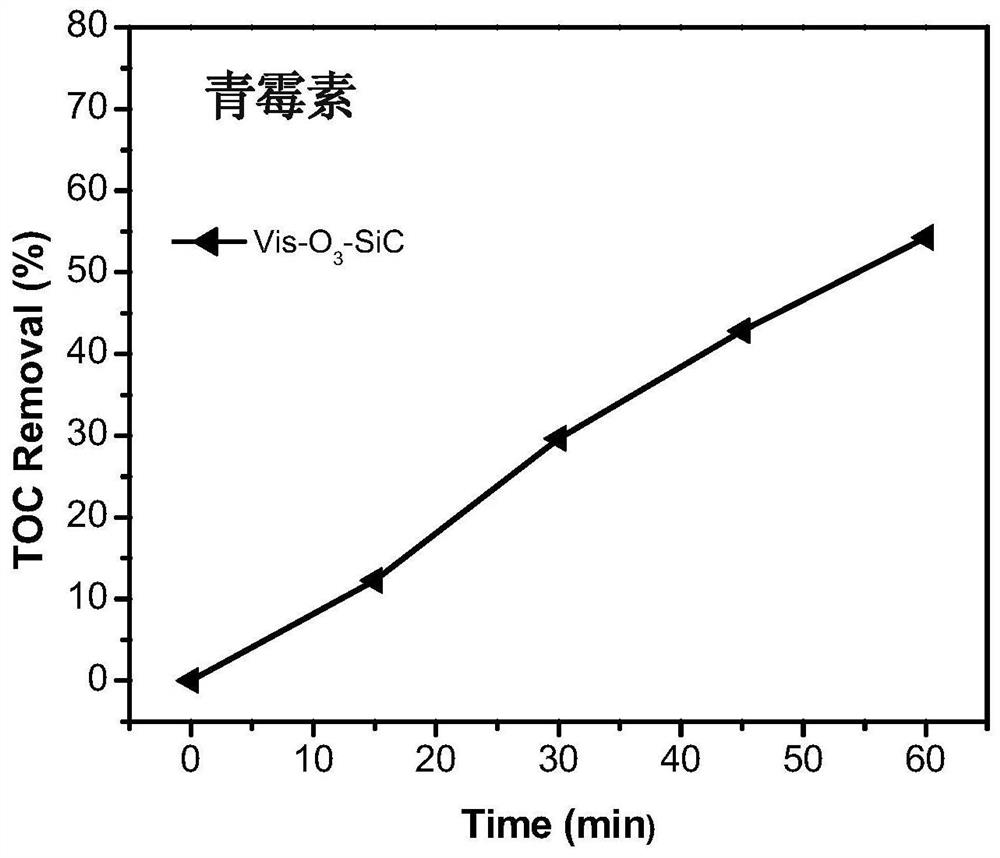

[0056] A method for removing penicillin (Penicillin G) in medical wastewater by ozone-visible light catalysis, comprising the steps:

[0057] In the continuous reactor, the effective volume of the reaction solution is 150mL, and the initial concentration of penicillin is 36mg / L; a plug-in visible light source is used, silicon carbide is coated and fixed on the inner wall of the cylindrical reactor, and the light wavelength ranges from 420 to 800nm. 130mW / cm 2 , the distance between the outer wall of the light source and the inner wall of the reactor is 1 cm. The flow rate of the ozone mixed gas is 100mL / min, and the ozone concentration is 20mg / L; after the simulated wastewater enters the reactor, the visible light source is turned on and the ozone mixed gas is continuously fed into the reactor at the same time; the flow rate of the wastewater to be treated is adjusted to control the reaction The effective residence time in the device is 1 hour, the concentration of penicillin...

Embodiment 3

[0061] A method for removing oxalic acid in organic waste water with ozone visible light, comprising the steps of:

[0062] A semi-continuous reactor is used, the volume of the reaction solution is 300mL, and the concentration of oxalic acid is 180mg / L; the outer cover type xenon lamp light source is placed vertically above the reactor, and a filter is used to filter out the visible light region, so that the light source only emits visible light. 420~800nm, the light intensity is 490mW / cm 2 The flow velocity of the ozone gas mixture is 100mL / min, and the ozone concentration is 20mg / L; 60mg of silicon carbide is weighed and put into the reaction solution, the catalyst concentration is 0.2g / L, after the solid-liquid is fully mixed, the ultraviolet light source is turned on and simultaneously to the reaction solution The ozone mixture was continuously fed into the container; the reaction time was 1 hour, and samples of different periods were kept, and the concentration of the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com