Bismuth oxybromide-copper oxide nano composite photo catalyst and preparation method thereof

A bismuth oxybromide and nano-composite technology, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as limiting solar energy utilization, and achieve cheap raw materials, easy access to raw materials, and easy operation. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] ①. Preparation of bismuth oxybromide nanosheets

[0027] Weigh 3mmol of CTAB (about 1.0911g), 3mmol of Bi(NO 3 ) 3 ·5H 2 O (about 1.4551g) was put into the reaction kettle, added 55mL of distilled water, stirred for 25min to make it fully dissolved, then adjusted the pH of the solution to 4 with 1M NaOH solution, and continued to stir for 0.5h; after 30h at 160°C , naturally cooled to room temperature, suction filtered, dried, and collected to obtain round bismuth oxybromide nanosheets.

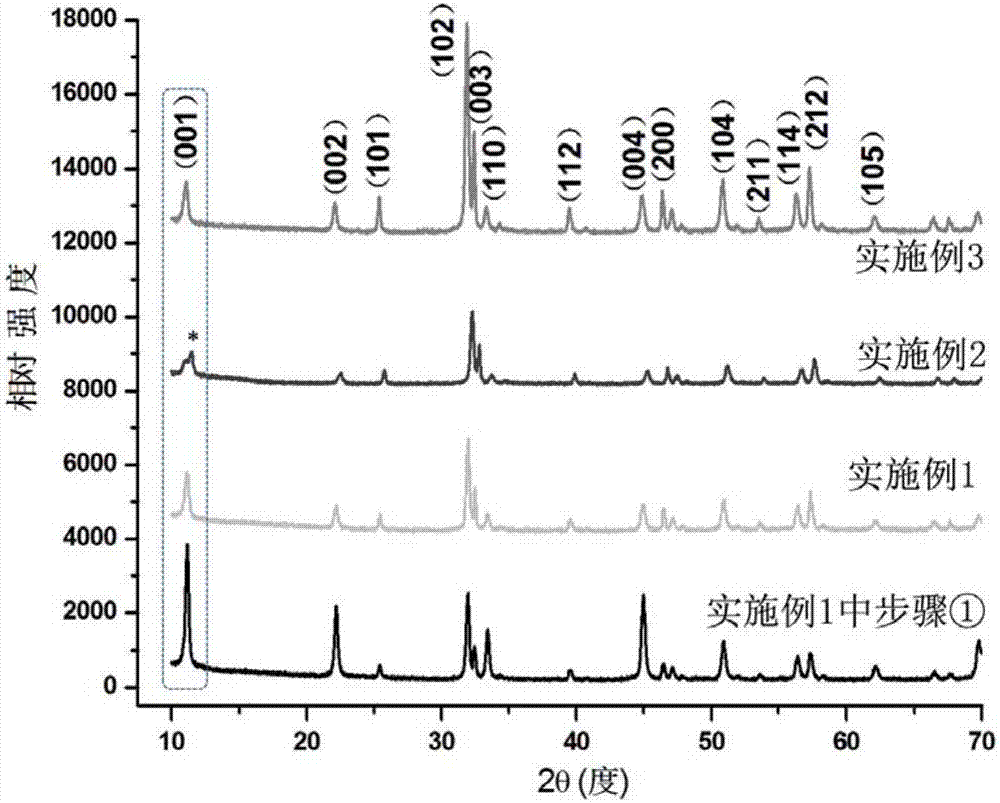

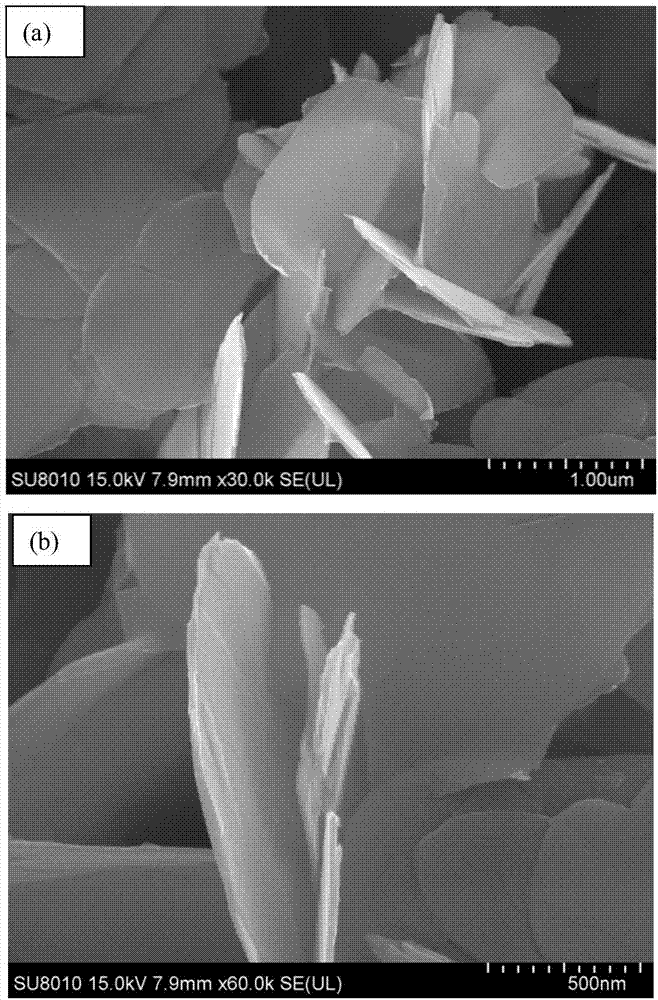

[0028] See attached figure 1 , by the X-ray powder diffraction analysis (XRD) spectrogram of the bismuth oxybromide nanosheet that the method described in step 1. in embodiment 1 makes. The peak positions of the spectral lines in the figure correspond to all the diffraction crystal planes of the JCPDF standard card (09-0393), and the index is the tetragonal BiOBr crystal, the space group P4 / nmm, and the lattice constant No impure diffraction peaks were found, indicating that pure...

Embodiment 2

[0035] ①. Preparation of bismuth oxybromide nanosheets

[0036] Weigh 2mmol of CTAB (about 0.7274g), 2mmol of Bi(NO 3 ) 3 ·5H 2 O (about 0.9700g) is put into the reaction kettle, add 45mL of distilled water, stir for 15min to make it fully dissolved, then adjust the pH of the solution to 3 with 1M NaOH solution, and continue to stir for 1.5h; keep warm at 180°C for 10h , naturally cooled to room temperature, suction filtered, dried, and collected to obtain round bismuth oxybromide nanosheets.

[0037] ②. Reaction on bismuth oxybromide nanosheets to form copper oxide nanocrystals

[0038] Take a round bottom flask, add 0.0915g of bismuth oxybromide (about 0.328mmol) nanosheets, 1mL of distilled water and 29mL of DMF, ultrasonically disperse for 25min; then add 0.3mmol of Cu(CH 3 COO) 2 ·H 2 O, stir to dissolve; transfer the solution to an ultrasonic reactor (cylindrical, 50W), the temperature of the water bath is 80°C, and the ultrasonic irradiation time is 60min. After t...

Embodiment 3

[0042] ①. Preparation of bismuth oxybromide nanosheets

[0043] Weigh 2.5mmol of CTAB (about 0.9093g), 2.5mmol of Bi(NO 3 ) 3 ·5H 2 O (about 1.2126g) was put into the reaction kettle, added 50mL of distilled water, stirred for 20min to make it fully dissolved, then adjusted the pH of the solution to 2 with 1M NaOH solution, and continued to stir for 1h; after insulated at 170°C for 17h, Naturally cooled to room temperature, suction filtered, dried, and collected to obtain round bismuth oxybromide nanosheets.

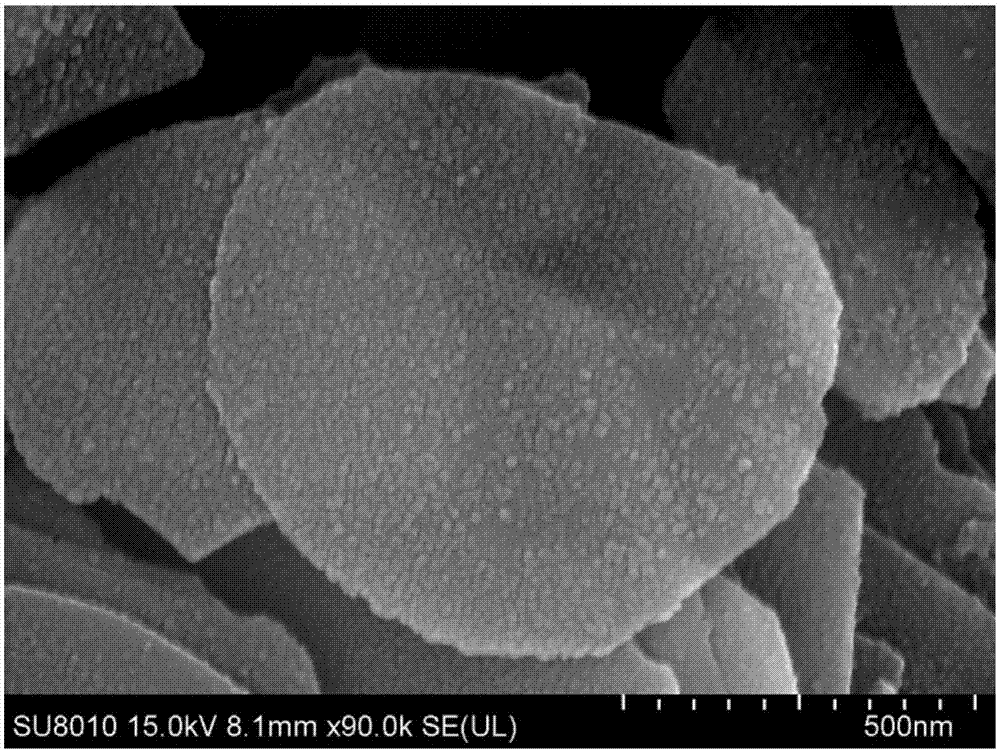

[0044] ②. Reaction on bismuth oxybromide nanosheets to form copper oxide nanocrystals

[0045] Take a round bottom flask, add 0.1219g of bismuth oxybromide (about 0.4mmol) nanosheets, 1mL of distilled water and 29mL of DMF, ultrasonically disperse for 20min; then add 0.5mmol of Cu(CH 3 COO) 2 ·H 2 O, stir to dissolve; transfer the solution to an ultrasonic reactor (cylindrical, 50W), the temperature of the water bath is 80°C, and the ultrasonic irradiation time is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com