Sodium alginate-chitosan polyionic compound hydrogel and its 3D-printing preparation method

A polyion complex, sodium alginate technology, applied in medical science, prosthesis, additive processing, etc., can solve the problems of reduced mechanical properties of hydrogel materials, unfavorable cell adhesion and proliferation, etc., to improve the degradation mode, The effect of reducing bleed and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The preparation of sodium alginate-chitosan polyion complex hydrogel specifically comprises the steps:

[0041] (1) Preparation of sodium alginate-chitosan polyion complex solution:

[0042] Take 5g of sodium alginate powder (Aladdin, S100126) and add it to 50ml of deionized water, stir thoroughly with a magnetic stirrer (IKA® KW20) for 2 hours at room temperature to obtain a sodium alginate solution with a concentration of 0.1g / mL, and then add 5g Chitosan powder (Aladdin, deacetylation degree ≥ 95%), continue to stir well for 2 hours to disperse the chitosan powder evenly in the sodium alginate solution, and prepare sodium alginate-chitosan with a concentration of 0.20g / mL Polyion complex solution (in the solution, the mass ratio of sodium alginate to chitosan is 1:1);

[0043] (2) Preparation of sodium alginate-chitosan polyion complex hydrogel:

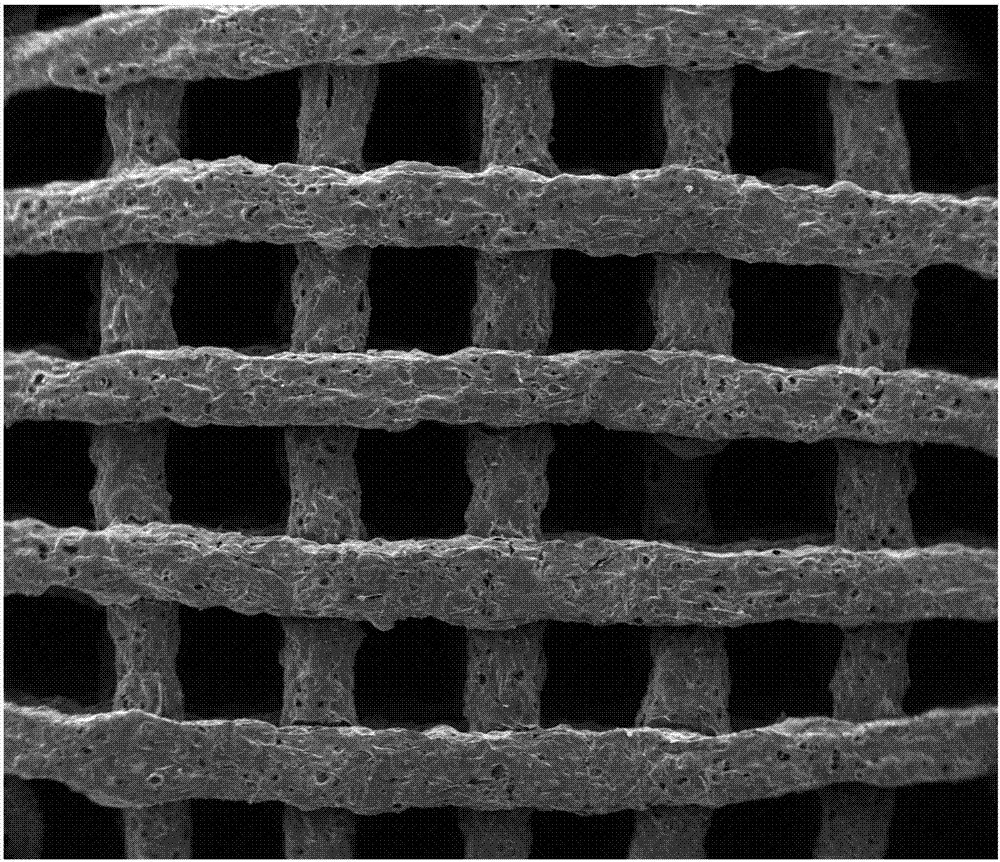

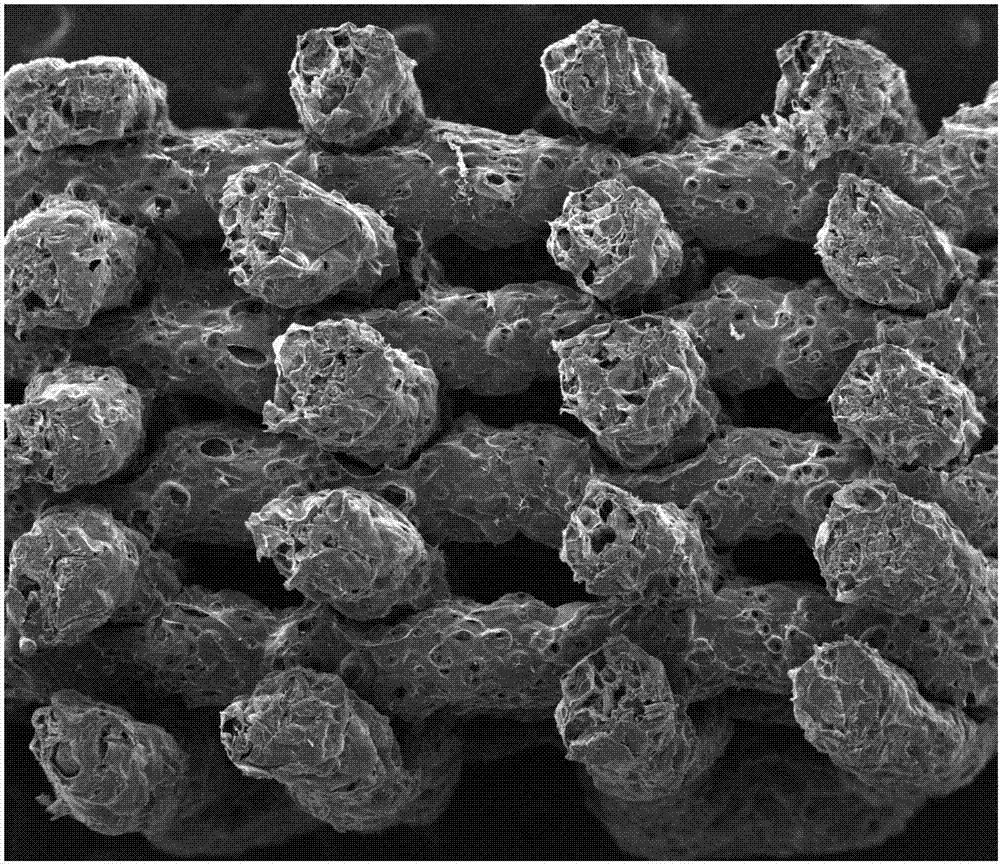

[0044] Put the sodium alginate-chitosan polyion complex solution into a 30 cc injection plastic cylinder, design a cuboid...

Embodiment 2

[0046] The preparation of sodium alginate-chitosan polyion complex hydrogel specifically comprises the steps:

[0047] (1) Preparation of sodium alginate-chitosan polyion complex solution:

[0048] Take 5.45g of sodium alginate powder (Aladdin, S100126) and add it to 50ml of deionized water, stir thoroughly with a magnetic stirrer (IKA® KW20) at room temperature for 2 hours to obtain a sodium alginate solution with a concentration of 0.109g / mL, and then add 4.55 g of chitosan powder (Aladdin, degree of deacetylation ≥ 95%), continue to stir well for 2 h to disperse the chitosan powder evenly in the sodium alginate solution, and prepare sodium alginate-shell with a concentration of 0.20 g / mL Polycan polyion complex solution (in the solution, the mass ratio of sodium alginate to chitosan is 6:5);

[0049] (2) Preparation of sodium alginate-chitosan polyion complex hydrogel:

[0050] Put the sodium alginate-chitosan polyion complex solution into a 30 cc injection plastic cylind...

Embodiment 3

[0052] The preparation of sodium alginate-chitosan polyion complex hydrogel specifically comprises the steps:

[0053] (1) Preparation of sodium alginate-chitosan polyion complex solution:

[0054] Take 4.44g of sodium alginate powder (Aladdin, S100126) and add it to 50ml of deionized water, and stir it with a magnetic stirrer (IKA® KW20) at room temperature for 2 hours to obtain a sodium alginate solution with a concentration of 0.0888g / mL, and then add 5.56 g of chitosan powder (Aladdin, deacetylation degree ≥ 95%), continue to stir well for 2 h to disperse the chitosan powder evenly in the sodium alginate solution, and prepare sodium alginate-shell with a concentration of 0.20 g / mL Polycan polyion complex solution (in the solution, the mass ratio of sodium alginate to chitosan is 4:5);

[0055] (2) Preparation of sodium alginate-chitosan polyion complex hydrogel:

[0056] Put the sodium alginate-chitosan polyion complex solution into a 30 cc injection plastic cylinder, de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com