Black master batch for near-infrared classification as well as preparation method and application of black master batch

A black masterbatch and near-infrared technology, applied in the field of color masterbatch, can solve the problems of unrecognizable plastic products and the impact of recycled plastic product efficiency, and achieve the effects of easy identification, improved efficiency, and improved reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12

[0042] Embodiment 1 is taken as an example below for description.

Embodiment 1

[0043] The black masterbatch that embodiment 1 relates to is used for near-infrared classification, and its preparation method is as follows:

[0044] (1) Mix 80kg iron black, 5kg ferrous oxide powder, and 3kg sodium polyacrylate to obtain mixture 1;

[0045] (2) Add mixture 1 and 160kgPP into the kneader, and knead at 185°C to obtain mixture 2;

[0046] (3) Using 40kg of aluminum powder and mixture 2 as raw materials, the mixture 1 was added into a screw extruder, and extruded and granulated at 150°C to obtain black masterbatches for near-infrared classification.

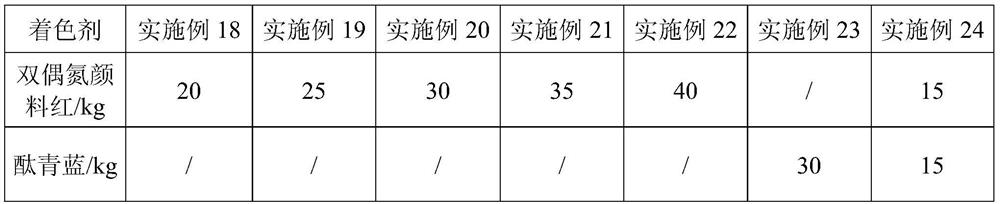

[0047] As shown in Table 1, the difference between Examples 1-10 is mainly in the ratio of raw materials, and the difference in Examples 10-13 is mainly in the average particle size of iron black.

[0048] Table 1

[0049]

Embodiment 14

[0051] The difference between this example and Example 12 is that 30kg of steel slag is added to the formula, and the steel slag is kneaded together with other raw materials in step (2).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com