Ultrasonic-assisted titanium silicalite molecular sieve modification method

A technology of titanium-silicon molecular sieve and ultrasonic wave, applied in molecular sieve catalysts, molecular sieves and base exchange compounds, chemical instruments and methods, etc., can solve problems such as large grain size, difficult grafting of metal compounds, large pore size and unfavorable catalysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

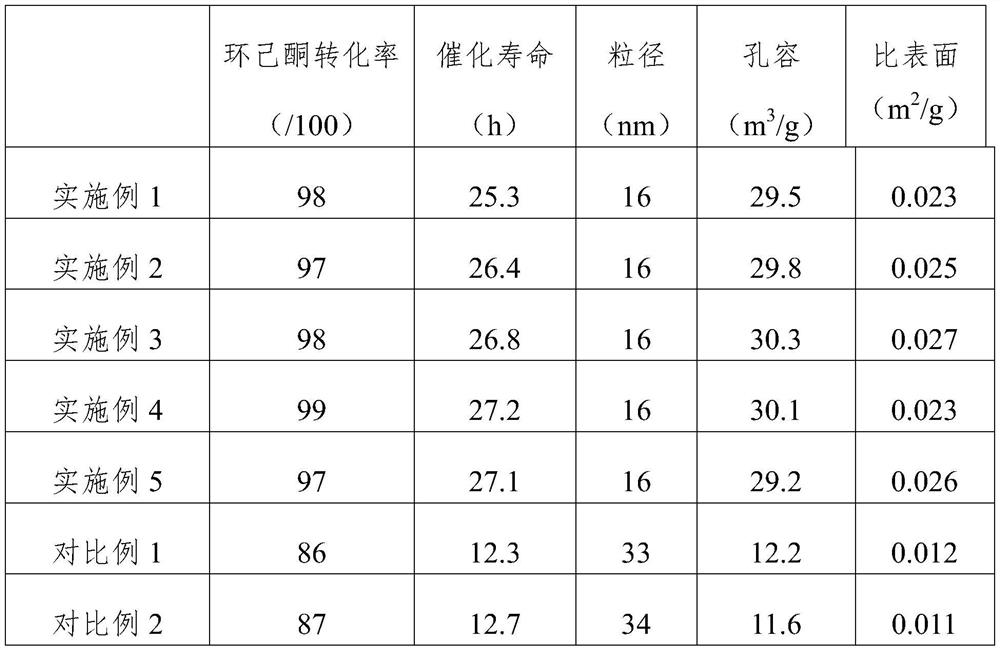

Examples

Embodiment 1

[0027] A method for modifying titanium-silicon molecular sieves assisted by ultrasonic waves, the steps of the modification method are as follows:

[0028] S1: After mixing the original silicon molecular sieve powder mother liquor, template agent and mesoporous silica in proportion, the temperature is raised once to remove alcohol. The molar ratio of n-butyl ester, templating agent, mesoporous silica and tetra-n-butyl titanate is 42:14.8:1;

[0029] S2: After the alcohol is removed by heating, the mixed solution is heated for the second time to remove the alcohol. The temperature of the second temperature rise is 83 ° C, and the time for removing the alcohol is 4.5 hours, and the titanium-silicon colloidal reaction solution is prepared, and the titanium-silicon colloidal reaction is performed. The liquid is heated and crystallized. The temperature of the crystallization is 170°C, and the crystallization time is 65h. The obtained solid-liquid mixture is subjected to solid-liqui...

Embodiment 2

[0035] A method for modifying titanium-silicon molecular sieves assisted by ultrasonic waves, the steps of the modification method are as follows:

[0036] S1: After mixing the original silicon molecular sieve powder mother liquor, template agent and mesoporous silica in proportion, the temperature is raised once to remove alcohol. The molar ratio of n-butyl ester, templating agent, mesoporous silica and tetra-n-butyl titanate is 33:5.5:1;

[0037] S2: After the alcohol is removed by heating, the mixed solution is heated and removed for the second time. The temperature of the second temperature rise is 95 ° C, and the time of alcohol removal is 4.8 hours, and the titanium-silicon colloidal reaction solution is prepared, and the titanium-silicon colloidal reaction is carried out. The liquid is heated and crystallized, the temperature of the crystallization is 195°C, and the crystallization time is 55h. The obtained solid-liquid mixture is subjected to solid-liquid separation to...

Embodiment 3

[0043] A method for modifying titanium-silicon molecular sieves assisted by ultrasonic waves, the steps of the modification method are as follows:

[0044] S1: After mixing the original silicon molecular sieve powder mother liquor, template agent and mesoporous silica in proportion, the temperature is raised once to remove the alcohol. The molar ratio of n-butyl ester, templating agent, mesoporous silica and tetra-n-butyl titanate is 36:9.8:1;

[0045] S2: After the alcohol is removed by heating, the mixed solution is heated and removed for the second time. The temperature of the second temperature rise is 87 ° C, and the time of alcohol removal is 5.3 hours, and the titanium-silicon colloidal reaction solution is prepared, and the titanium-silicon colloidal reaction is carried out. The liquid is heated and crystallized, the temperature for crystallization is 178°C, and the crystallization time is 58h. The obtained solid-liquid mixture is subjected to solid-liquid separation t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com