High-voltage charge pump circuit

A charge pump and circuit technology, applied to electrical components, conversion equipment without intermediate conversion to AC, output power conversion devices, etc., can solve the problems of long start-up time, low start-up efficiency, and inapplicability, and achieve the charging and discharging process. Stable, compact circuit structure, stable voltage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the drawings and embodiments.

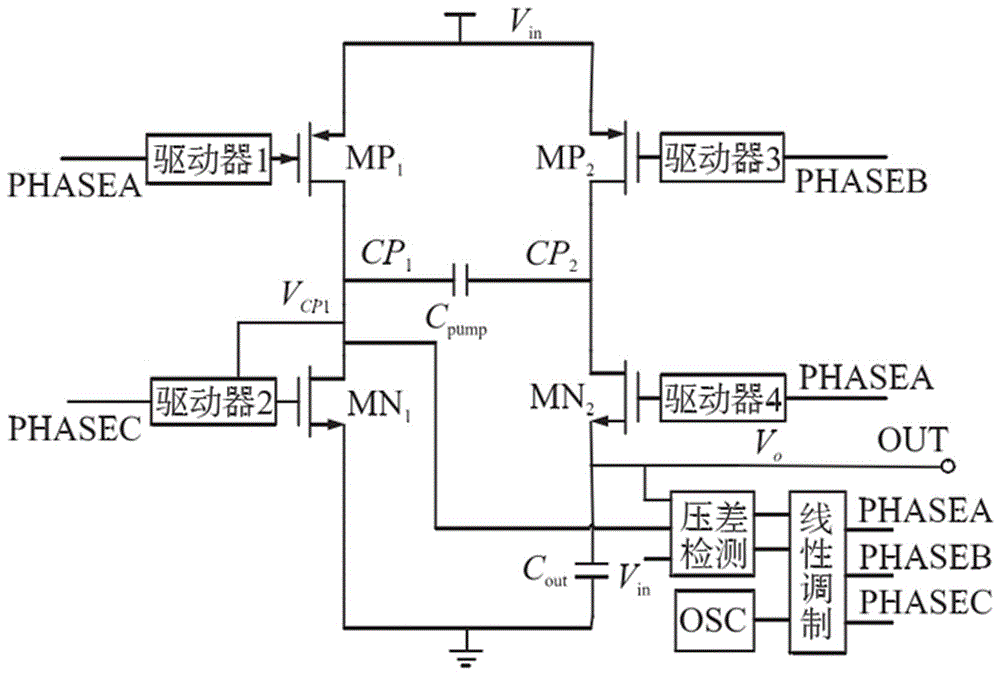

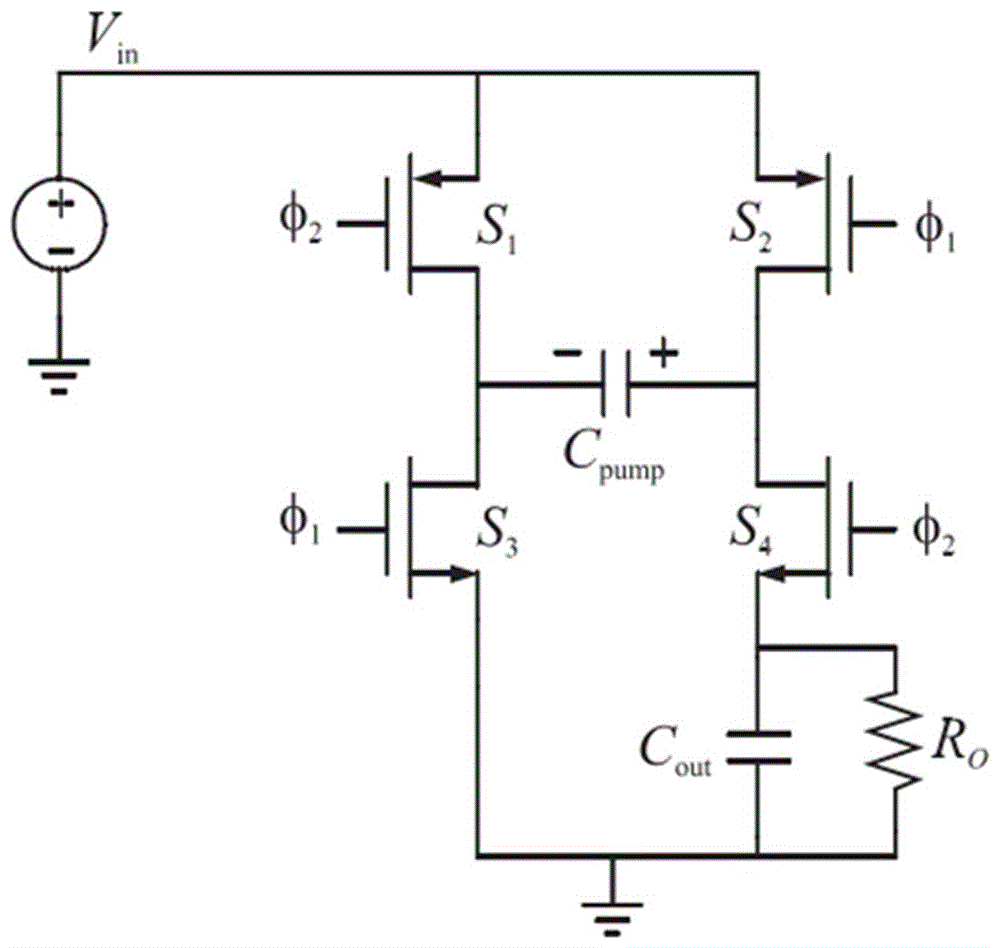

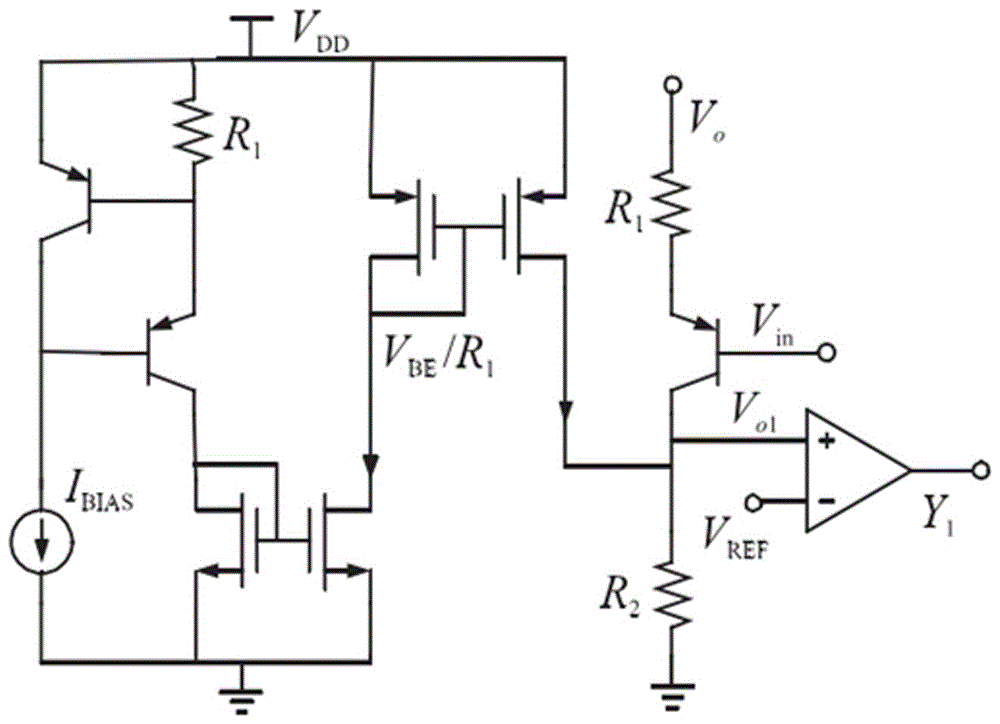

[0019] Such as figure 1 , The switch tube in the new charge pump circuit adopts a new type of power MOSFET, and the input and output voltage range of the circuit reaches 13 V~45V. The driver completes the shift function of controlling brainwashing, and controls the on and off of the switch tube. A high-voltage differential detection circuit is designed in the circuit to detect the difference between the left plate voltage of the pump capacitor and the output voltage and the power supply voltage, and use the detection result as the input signal of the linear modulation circuit to generate a feedback signal. The driver 2 is a current control circuit, which controls the charging current of the MN1 tube and improves the starting efficiency of the circuit. Under the control of the feedback loop, the output voltage changes linearly with the input voltage, the output voltage i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com