A high-efficiency wood-plastic panel cooling equipment

A technology for cooling equipment and wood-plastic panels, applied in the field of high-efficiency wood-plastic panel cooling equipment, can solve the problems of low cooling efficiency, high labor intensity, inconvenient operation, etc., to improve cooling efficiency, good cooling ability, and achieve cooling effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

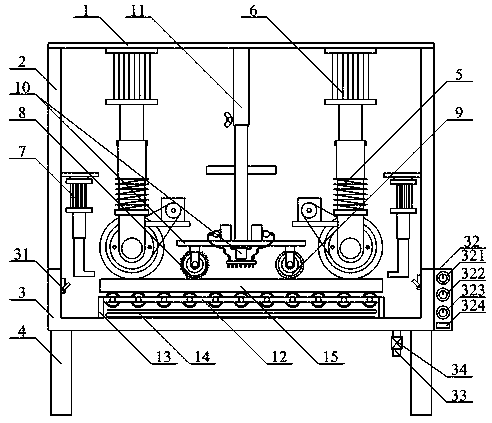

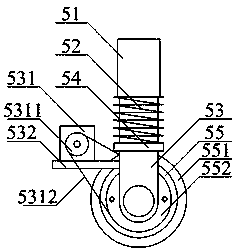

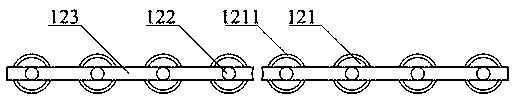

[0055] as attached figure 1 to attach Figure 8 shown

[0056] The invention provides a high-efficiency wood-plastic board cooling device, which includes a beam 1, a longitudinal support beam 2, a water cooling tank 3, a supporting foot 4, a main cooling sliding machine device 5, a lifting cylinder 6, a lifting board device 7, and a cleaning device. Impurity brush device 8, quick-absorbing sponge wheel device 9, mixed liquid nozzle device 10, anti-scratch plate adjusting rod device 11, auxiliary cooling fixed wheel device 12, end plate 13, condensation pipe 14 and wood-plastic board body 15, the The left and right sides of the lower part of the crossbeam 1 are installed on the upper part of the water discharge cooling tank 3 with bolts through the longitudinal support beam 2 respectively; the support feet 4 are respectively installed at the bottom four corners of the water discharge cooling tank 3 with bolts; The sliding machine device 5 is installed on the output rod of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com