Preparation method of high-quality bean curd

A high-quality, tofu technology, applied in the field of food processing, can solve the problems of loose tofu, poor water-holding performance, and astringency, etc., and achieve the effects of increasing protein content, increasing water-holding capacity, and high water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Based on the above considerations, embodiments of the present invention provide a method for preparing high-quality tofu, comprising the following steps:

[0031] S1: Soybeans are washed, peeled, and soaked in water added with 0.2-0.4% sodium bicarbonate by volume for 10-12 hours at 4°C;

[0032] In the description of Chinese patent ZL2013104685075, it is recorded that in the preparation process of tofu, neutral water (preferably pH6.5-7) is required for soaking beans. Sexual conditions are conducive to the water swelling of beans. The inventor added 0.2-0.4% baking soda to the water of soaking beans. After adding baking soda, the water was alkaline. In order to prevent the alkaline solution from damaging the beans, the inventor creatively proposed to soak the beans for 10-10% at 4°C. 12 hours, not only avoiding the rot of the beans, but also adding baking soda can promote the swelling of the beans, and the beans soaked in baking soda also have a certain effect on remo...

Embodiment 1

[0053] Wash 1 kg of soybeans, peel them off, and soak them in water at 4°C for 10 hours; add baking soda with a water volume ratio of 0.2% to the water for soaking soybeans;

[0054] Add 6L of water to the soaked wet soybeans for pulping, and then pass through 80-100 mesh gauze to obtain raw soybean milk.

[0055] Microwave pretreatment of raw soybean milk (constant frequency 3.0GHz), processing time 1min, power 350W, add 10g trypsin, heat to 40°C and keep warm for 25min, then add 1.8g glutamine transaminase and keep warm for 60min, then boil for 10min, cool to At room temperature, 3kg of tofu is obtained.

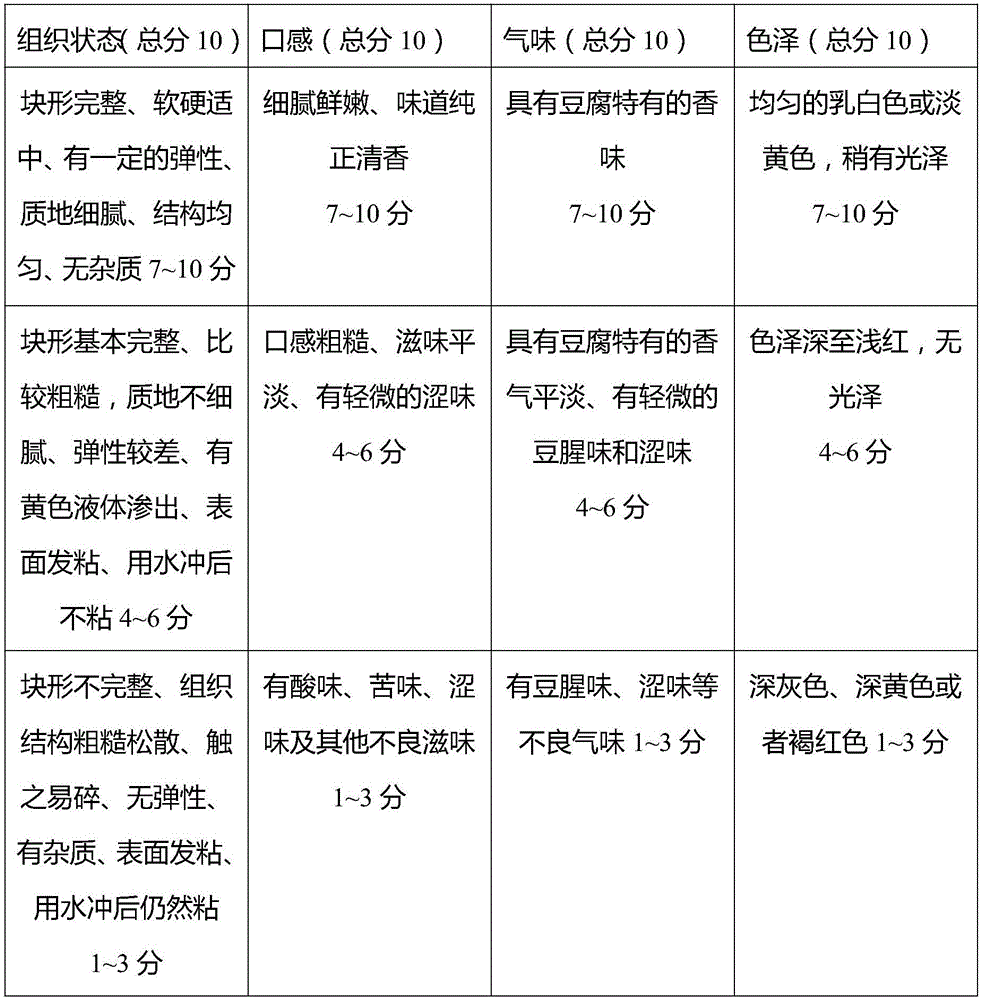

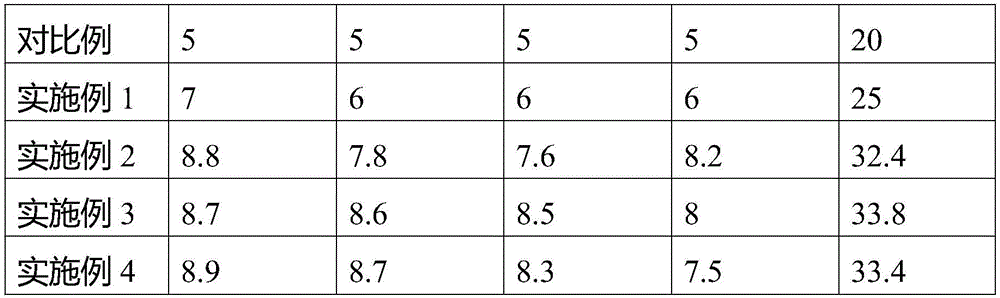

[0056] The sensory evaluation results of tofu are shown in Table 2 below, the purine content and water holding capacity of tofu are shown in Table 3 below, and the free amino acid content is shown in Table 4 below.

Embodiment 2

[0058] Wash 1 kg of soybeans, peel them off, and soak them in water at 4°C for 12 hours; add sodium bicarbonate with a water volume ratio of 0.4% to the water for soaking soybeans; soak soybeans in hot water at 70°C for 5 minutes.

[0059] Add 8L of water to the soaked wet soybeans for grinding, and then pass through 80-100 mesh gauze to obtain raw soybean milk.

[0060] Microwave pretreatment of raw soybean milk (constant frequency 3.0GHz), processing time 1min, power 350W, add 12g trypsin, heat to 40°C and keep warm for 35min, then add 2g transglutaminase and keep warm for 65min, then boil for 10min, cool to room temperature That is to say, 3.5kg of tofu is obtained.

[0061] The sensory evaluation results of tofu are shown in Table 2 below, the purine content and water holding capacity of tofu are shown in Table 3 below, and the free amino acid content is shown in Table 4 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com