Novel CH3NH3PbI3/polyimide composite material and preparation method thereof

A technology of polyimide and composite materials, which is applied in the field of new CH3NH3PbI3/polyimide composite materials and its preparation, can solve the problem of difficult to prepare perovskite films in large quantities, limit the development of solar cells, and perovskite formation. Poor film properties and other problems, to achieve good film-forming properties, outstanding mechanical properties and dielectric properties, and difficult to form films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

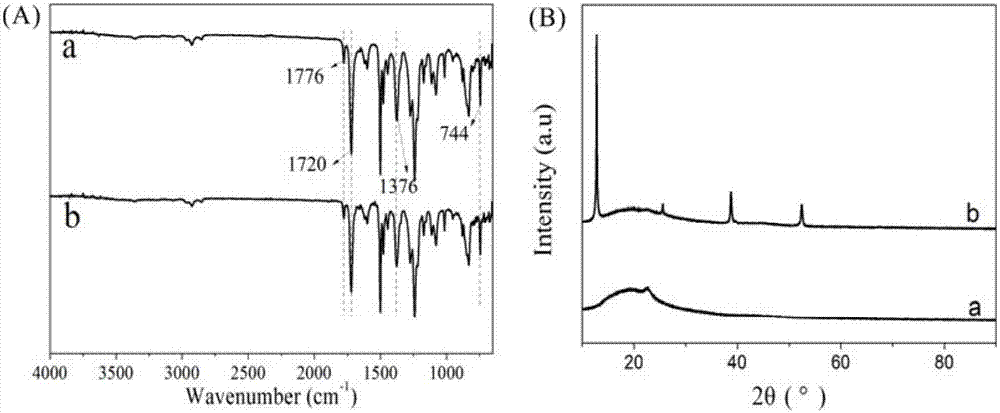

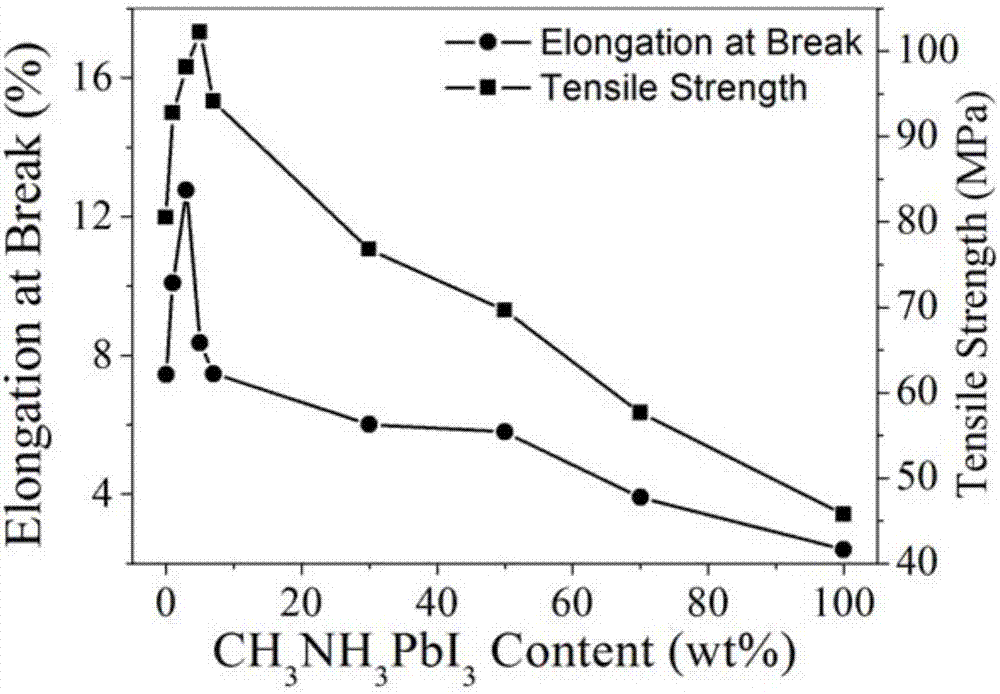

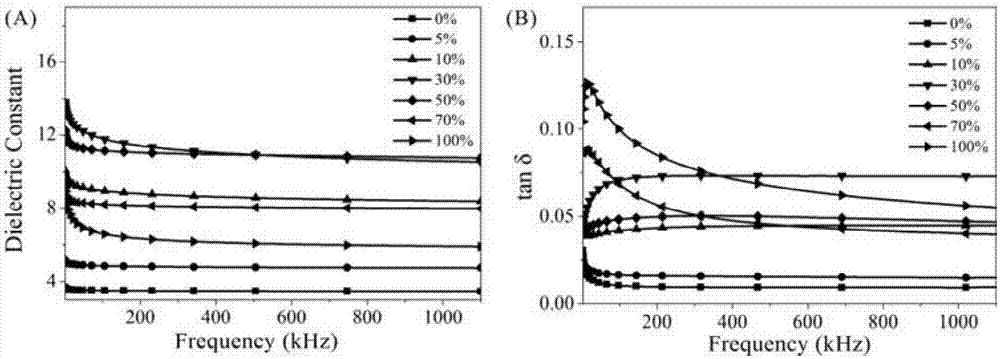

[0026] A new type of CH 3 NH 3 PB 3 The preparation method of / polyimide composite material specifically comprises the following steps:

[0027] (1)CH 3 NH 3 I and CH 3 NH 3 PB 3 Preparation: Take equimolar methylamine and hydroiodic acid into the flask, and stir for 2 hours under the protection of nitrogen at 0°C, then obtain the precipitated product by rotary evaporation, put it in an oven at 80°C for 12 hours, and obtain a dry CH 3 NH 3 I. Take equimolar CH 3 NH 3 I and PbI 2 Dissolved in anhydrous dimethylformamide (DMF) solution, and stirred at 60°C under nitrogen protection for 2h to obtain CH 3 NH 3 PB 3 .

[0028](2) Preparation of polyimide (PI): get 4mmol diaminodiphenyl ether (ODA) and 4mmol bisphenol A dianhydride (BPADA) and be dissolved in the dimethylformamide (DMF) solution of 80ml, and in Stir at 40°C under nitrogen protection for 12h, then add 2.4ml of pyridine and 4.8ml of acetic anhydride to the solution, and stir at 60°C for 6h, then at 80°...

Embodiment 2

[0031] A new type of CH 3 NH 3 PB 3 The preparation method of / polyimide composite material specifically comprises the following steps:

[0032] (1)CH 3 NH 3 I and CH 3 NH 3 PB 3 Preparation: Add equimolar methylamine and hydroiodic acid into a flask, and stir for 2 hours at 0°C under the protection of nitrogen, then obtain the precipitated product by rotary evaporation, put it in an oven at 80°C for 12 hours, and obtain a dry CH 3 NH 3 I. Take equimolar CH 3 NH 3 I and PbI 2 Dissolved in anhydrous dimethylformamide (DMF) solution, and stirred at 60°C under nitrogen protection for 2h to obtain CH 3 NH 3 PB 3 .

[0033] (2) Preparation of polyimide (PI): get 4mmol diaminodiphenyl ether (ODA) and 4mmol bisphenol A dianhydride (BPADA) and be dissolved in the dimethylformamide (DMF) solution of 80ml, and in Stir at 40°C under nitrogen protection for 12h, then add 2.4ml of pyridine and 4.8ml of acetic anhydride to the solution, and stir at 60°C for 6h, then at 80°C ...

Embodiment 3

[0036] A new type of CH 3 NH 3 PB 3 The preparation method of / polyimide composite material specifically comprises the following steps:

[0037] (1)CH 3 NH 3 I and CH 3 NH 3 PB 3 Preparation: Add equimolar methylamine and hydroiodic acid into a flask, and stir for 2 hours at 0°C under the protection of nitrogen, then obtain the precipitated product by rotary evaporation, put it in an oven at 80°C for 12 hours, and obtain a dry CH 3 NH 3 I. Take equimolar CH 3 NH 3 I and PbI 2 Dissolved in anhydrous dimethylformamide (DMF) solution, and stirred at 60°C under nitrogen protection for 2h to obtain CH 3 NH 3 PB 3 .

[0038] (2) Preparation of polyimide (PI): get 4mmol diaminodiphenyl ether (ODA) and 4mmol bisphenol A dianhydride (BPADA) and be dissolved in the dimethylformamide (DMF) solution of 80ml, and in Stir at 40°C under nitrogen protection for 12h, then add 2.4ml of pyridine and 4.8ml of acetic anhydride to the solution, and stir at 60°C for 6h, then at 80°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com