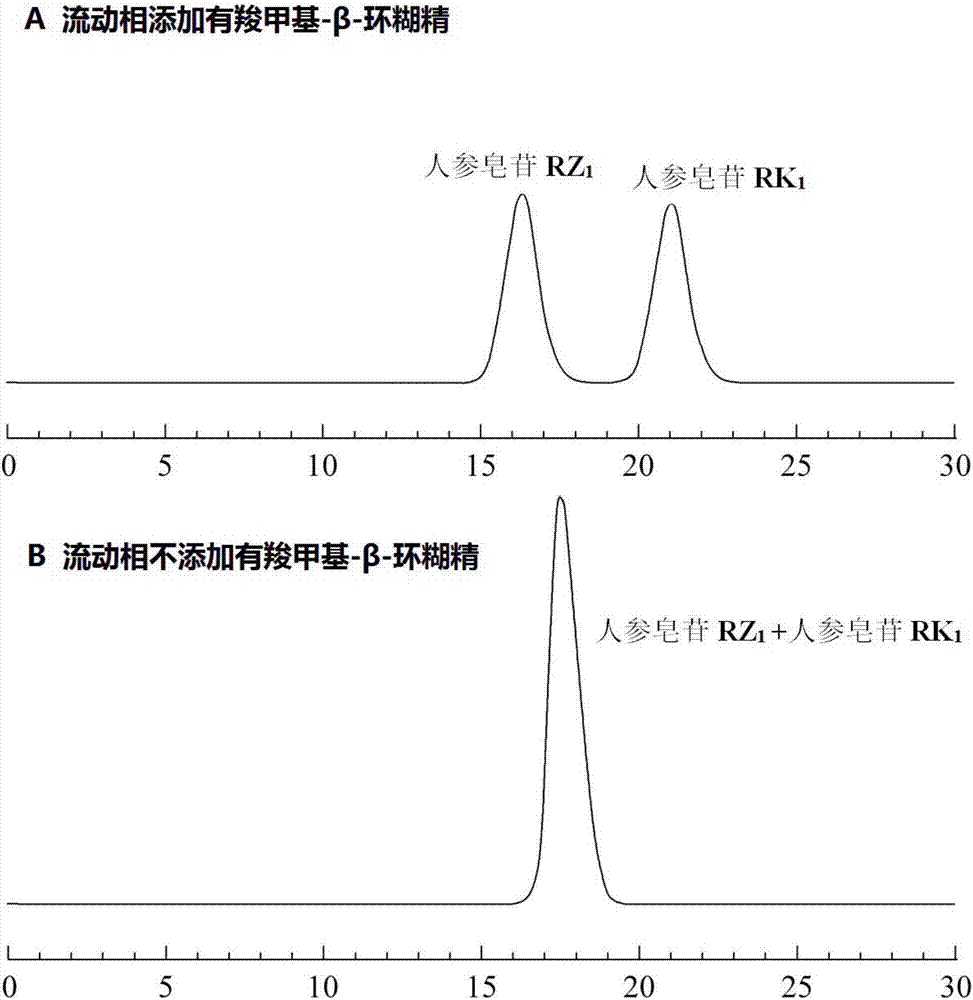

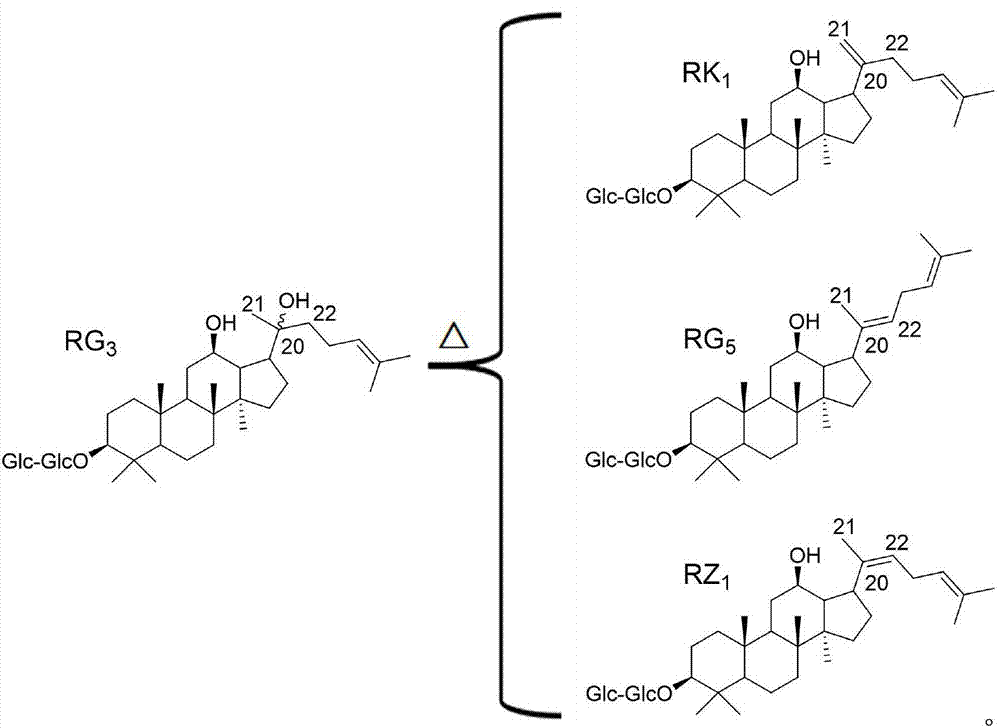

Method for measuring isomer impurity ginsenoside RK1 in ginsenoside RZ1 raw material or preparation

A technology of ginsenosides and isomers, applied in the field of drug analysis, can solve the problems of poor reproducibility, inability to meet drugs, immature development of two-dimensional liquid chromatography, etc., and achieve the effect of high resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: mobile phase is aqueous methanol

[0029] 1. Test material

[0030] Waters2695 liquid chromatograph (Waters, USA);

[0031] Sartorius electronic balance (Germany Sartorius);

[0032] Column: Waters XBridge TM C18 chromatographic column (5μm, 4.6×250mm; Waters, USA);

[0033] Ginsenoside RZ 1 and ginsenoside RK 1 The standard products are self-made, and the purity is greater than 98%;

[0034] Methanol, 85% phosphoric acid and triethylamine are chromatographically pure, water is deionized water, and carboxymethyl-β-cyclodextrin is analytically pure.

[0035] 2. Test method and test results

[0036] 2.1 Solution preparation

[0037] Chromatographic peak positioning solution: prepared containing ginsenoside RZ 1 or ginsenoside RK 1 single standard solution, concentration 0.1mg / mL.

[0038] System Suitability Solution: Formulating Ginsenoside RZ 1 and ginsenoside RK 1 The mixed standard solution with a concentration of 0.5 mg / mL was used as the...

Embodiment 2

[0061] Embodiment 2: mobile phase is acetonitrile aqueous solution

[0062] 1. Test material

[0063] Waters2695 liquid chromatograph (Waters, USA);

[0064] Sartorius electronic balance (Germany Sartorius);

[0065] Column: Waters XBridge TM C18 chromatographic column (5μm, 4.6×250mm; Waters, USA);

[0066] Ginsenoside RZ 1 and ginsenoside RK 1 The standard products are self-made, and the purity is greater than 98%;

[0067] Acetonitrile, 85% phosphoric acid, and triethylamine are chromatographically pure, water is deionized water, and carboxymethyl-β-cyclodextrin is analytically pure.

[0068] 2. Test method and test result

[0069] 2.1 Solution preparation

[0070] Chromatographic peak positioning solution: prepared containing ginsenoside RZ 1 or ginsenoside RK 1 single standard solution, concentration 0.1mg / mL.

[0071] System Suitability Solution: Formulating Ginsenoside RZ 1 and ginsenoside RK 1 The mixed standard solution with a concentration of 0.5 mg / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com