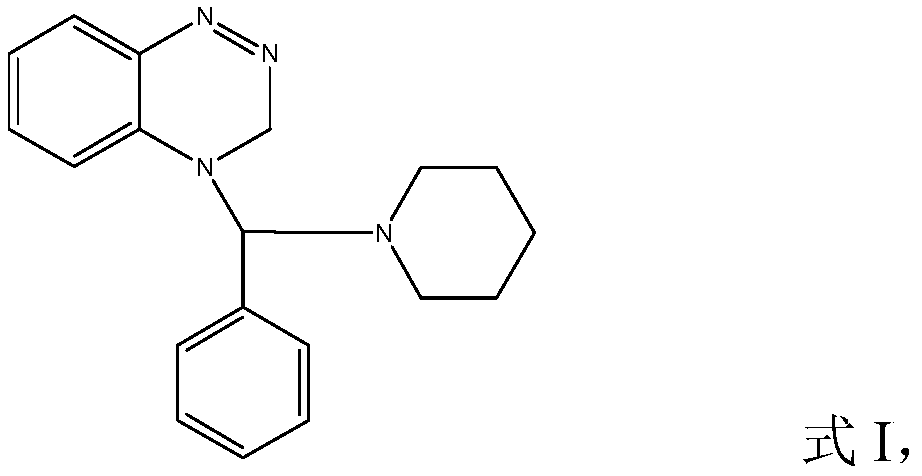

A quinoline derivative and a novel Mannich base composite acidifying corrosion inhibitor

A technology of acidifying corrosion inhibitor and Mannich base, which is applied in the direction of organic chemistry, drilling composition, chemical instruments and methods, etc., and can solve the problem of easy coking, insufficient stability, poor solubility and dispersion of corrosion inhibitors, etc. problems, to achieve the effects of wide application range, good stability, and improvement of acidizing construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

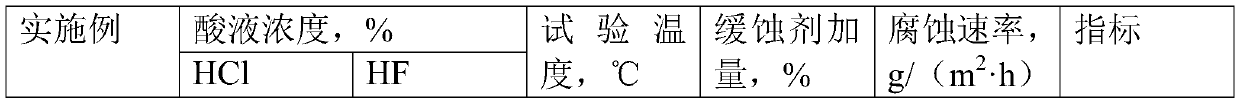

Embodiment 1

[0025] A quinoline derivative and novel Mannich base composite acidification corrosion inhibitor, including 12 parts by weight of corrosion inhibitor main agent A, 12 parts by weight of corrosion inhibitor main agent B, 0.5 parts by weight of heavy alkylbenzene sodium sulfonate, 3.0 parts by weight of propynyl alcohol, 0.5 parts by weight of potassium iodide, 1.0 parts by weight of cuprous chloride, 4.0 parts by weight of Pingpingjiao, 5.0 parts by weight of formic acid, 34.0 parts by weight of methanol, 23 parts by weight of PEG-400, 3.0 parts by weight of Acetaniline and 2.0 parts by weight of triethanolamine.

[0026] When in use, each component is weighed according to the above parts by weight and mixed evenly before being sent to the construction site for use or stored for later use.

Embodiment 2

[0028] A quinoline derivative and novel Mannich base composite acidification corrosion inhibitor, including 12 parts by weight of corrosion inhibitor main agent A, 12 parts by weight of corrosion inhibitor main agent B, 0.5 parts by weight of heavy alkylbenzene sodium sulfonate, 3.0 parts by weight of propynyl alcohol, 0.5 parts by weight of potassium iodide, 1.0 parts by weight of cuprous chloride, 4.0 parts by weight of Pingpingjiao, 5.0 parts by weight of formic acid, 34.0 parts by weight of methanol, 23 parts by weight of PEG-400, 3.0 parts by weight of Acetaniline and 2.0 parts by weight of triethanolamine.

[0029] When in use, each component is weighed according to the above parts by weight and mixed evenly before being sent to the construction site for use or stored for later use.

Embodiment 3

[0031] A quinoline derivative and novel Mannich base composite acidification corrosion inhibitor, including 12 parts by weight of corrosion inhibitor main agent A, 12 parts by weight of corrosion inhibitor main agent B, 0.5 parts by weight of heavy alkylbenzene sodium sulfonate, 3.0 parts by weight of propynyl alcohol, 0.5 parts by weight of potassium iodide, 1.0 parts by weight of cuprous chloride, 4.0 parts by weight of Pingpingjiao, 5.0 parts by weight of formic acid, 34.0 parts by weight of methanol, 23 parts by weight of PEG-400, 3.0 parts by weight of Acetaniline and 2.0 parts by weight of triethanolamine.

[0032] When in use, each component is weighed according to the above parts by weight and mixed evenly before being sent to the construction site for use or stored for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com