Environment-friendly drilling fluid strong in plugging property

A plugging, environmentally friendly technology, applied in drilling compositions, chemical instruments and methods, etc., can solve problems such as toxic raw materials and groundwater pollution, achieve good shale hydration, achieve direct discharge, and prevent jamming. drill effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

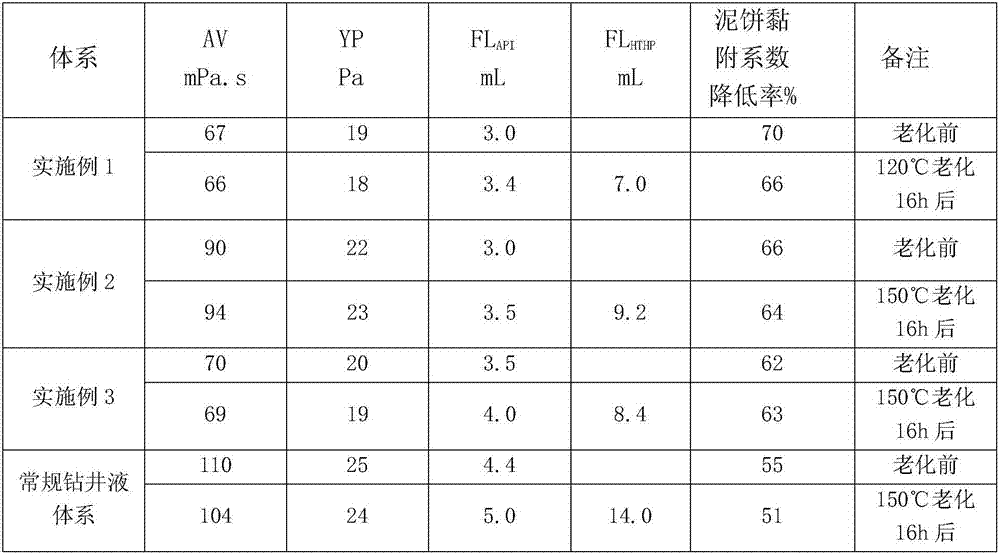

Examples

Embodiment 1

[0025] The invention provides an environment-friendly drilling fluid with strong plugging properties, which includes 2% bentonite, 0.3% sodium carbonate, 0.3% polyamine, 0.2% low-viscosity polyanionic cellulose, and 0.3% xanthan gum , 2% pregelatinized tapioca starch, 2% plugging agent, 1% 600 mesh calcium carbonate, 0.5% castor oil modified lubricant, 25% barite, and the contents of each component are mass contents, Measured by mass of water.

[0026] The preparation method of the plugging agent is as follows:

[0027] 1) Dissolve glucose into deionized water to make a glucose solution, then transfer the glucose solution to the liner as

[0028] In a tetrafluoroethylene hydrothermal synthesis kettle, react at 160°C for 6h, cool to room temperature after the reaction, centrifugally filter, wash three times with deionized water, and dry to obtain carbon spheres.

[0029] 2) Add sodium metaaluminate solution in a four-neck flask equipped with a mechanical stirrer, then add dil...

Embodiment 2

[0032] The invention provides an environment-friendly drilling fluid with strong plugging properties, which includes 6% bentonite, 0.5% sodium carbonate, 0.5% polyamino ether, 0.2% low-viscosity carboxymethyl cellulose, 0.3% hydroxyethyl Base cellulose, 0.1% xanthan gum, 8% pregelatinized tapioca starch, 5% plugging agent, 4% 1250 mesh calcium carbonate, 4% castor oil modified lubricant, 200% barite , the content of each component is the mass content, based on the mass of water.

[0033] The preparation method of described blocking agent is as follows:

[0034] 1) Same as Example 1, except that the hydrothermal reaction conditions are different, and the reaction is carried out at 180° C. for 4 hours.

[0035]2) Add sodium metaaluminate solution in a four-neck flask equipped with a mechanical stirrer, then add dilute sulfuric acid to adjust the pH of the solution to 4, then add urea and cetyltrimethylammonium bromide to the solution, stir , until the solution is clear, then a...

Embodiment 3

[0038] The present invention is an environment-friendly drilling fluid with strong plugging properties, including 4% bentonite, 0.4% sodium carbonate, 0.4% polyamine, 0.2% hydroxyethyl cellulose, 0.2% xanthan gum, 4% Pregelatinized tapioca starch, 3% plugging agent, 3% 1500 mesh calcium carbonate, 2% castor oil modified lubricant, 250% barite, the contents of each component are mass content, expressed as water quality meter.

[0039] The preparation method of described blocking agent is as follows:

[0040] 1) Same as Example 1, only the hydrothermal reaction conditions were different, and the reaction was carried out at 170° C. for 5 hours.

[0041] 2) Add sodium metaaluminate solution in a four-neck flask equipped with a mechanical stirrer, then add dilute sulfuric acid to adjust the pH of the solution to be 4, then add urea and cetyltrimethylammonium bromide to the solution, Stir until the solution is clear, then add the carbon spheres prepared in step 1 into a four-neck ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com