Emulsion composition for improving color of MBS resin powder, and resin prepared therefrom

A technology of emulsion composition and resin powder, applied in the field of MBS resin mixture, can solve the problems of high comprehensive cost, unhelpful resin color and heat resistance, affecting the transparency of MBS resin, etc., and achieve the effect of improving the aging resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

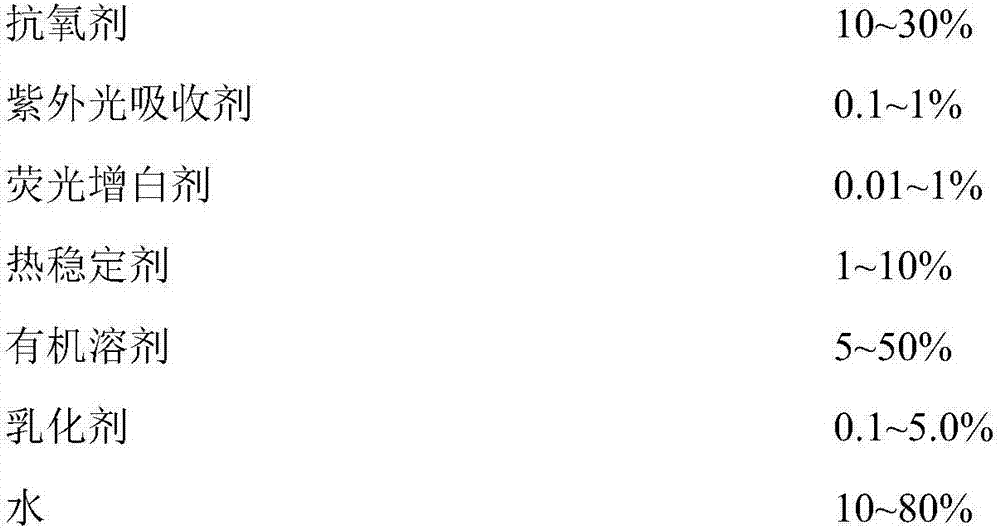

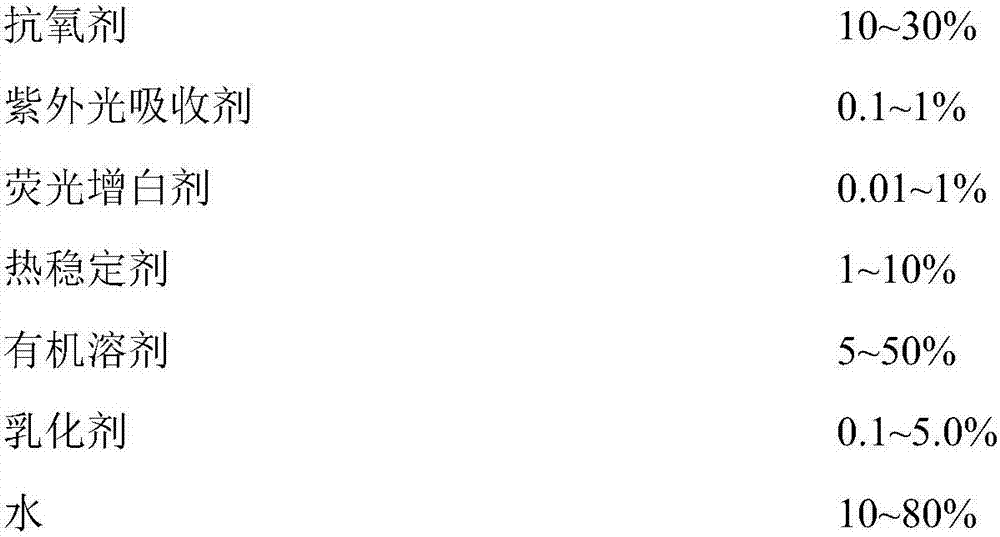

Method used

Image

Examples

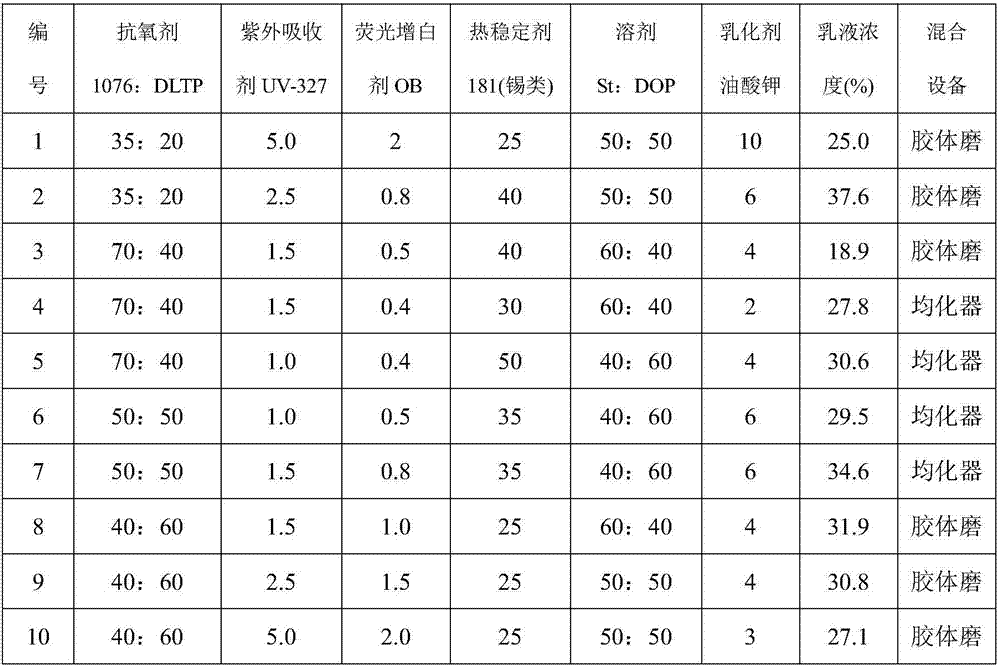

Embodiment 1~10

[0048] As shown in Table 1, after weighing each component of the emulsion in the embodiment according to the preparation formula, dissolve it with a solvent, and then mix it with the aqueous solution of the emulsifier. After mixing evenly, turn on the colloid mill or homogenizer, and pour the mixture solution into it at the same time, emulsify evenly and then unload.

[0049] At room temperature and stirring, add 0.5% of the dry solids of the above-mentioned emulsion into the MBS latex, mix well, add sulfuric acid aqueous solution at a certain temperature to break the emulsion, and then raise the temperature to the curing temperature to cure the MBS resin. Finally, the MBS resin was obtained by centrifugal drying. Visually inspect the whiteness, then measure the static thermal stability in a thermostat at 180°C, and measure the dynamic thermal stability on a double-roll mill at 180°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com