Preparation method of pentafluoropentanol

A technology of pentafluoropentanol and pentanol, which is applied in the field of preparation of synthetic intermediates, can solve problems such as difficulty in realizing industrialization, small pentafluoropentanol, and difficult control of the reaction process, and achieve high reaction yield and easy industrial production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

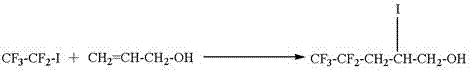

Method used

Image

Examples

Embodiment 1

[0044] (i) Add 110g of allyl alcohol and 500g of pentafluoroiodoethane into the autoclave, add 15g of azobisisobutyronitrile, add 800ml of water, control the temperature at 30°C~40°C, and stir for 4h~8h. After the reaction was completed, the lower organic phase was separated by standing. The organic phase was washed with water and dried to obtain 600 g of 4,4,5,5,5-pentafluoro-2-iodo-1-pentanol with a purity of 90%.

[0045] (ii) Add 50g of azobisisobutyronitrile to 500g of 4,4,5,5,5-pentafluoro-2-iodo-1-pentanol, slowly add 40g of platinum oxide catalyst, and control the reaction temperature to 60°C ~70℃, react for 3h-4h. After the reaction was completed, the upper organic phase was left standing to separate to obtain the pentafluoropentanol product with a quality of 260 g. The product was purified by rectification to obtain a pentafluoropentanol product with a purity greater than 99%.

Embodiment 2

[0047] (i) Add 110g propenyl alcohol and 600g pentafluoroiodoethane into the autoclave, add 20g cumene hydroperoxide, add 700ml water, 100ml acetonitrile, control the temperature at 40°C~50°C, and stir for 4h~8h. After the reaction, the lower organic phase was separated by standing. The organic phase was washed with water and dried to obtain 610 g of 4,4,5,5,5-pentafluoro-2-iodo-1-pentanol with a purity of 89%.

[0048] (ii) Add 40g of azobisisoheptanonitrile to 500g of 4,4,5,5,5-pentafluoro-2-iodo-1-pentanol, slowly add 40g of 5% palladium-carbon catalyst to control the reaction The temperature is 60°C~70°C, and the reaction time is 3h-4h. After the reaction was completed, the pentafluoropentanol product was obtained by filtration, with a quality of 260 g. The product was purified by distillation to obtain a pentafluoropentanol product with a purity greater than 99%.

Embodiment 3

[0050] (i) Add 110g of allyl alcohol and 400g of pentafluoroiodoethane into the autoclave, add 50g of ammonium persulfate, 25g of sodium bisulfite, add 900ml of water, control the temperature at 50°C~70°C, and stir for 4h~8h. After the reaction was completed, the lower organic phase was separated by standing. The organic phase was washed with water and dried to obtain 600 g of 4,4,5,5,5-pentafluoro-2-iodo-1-pentanol.

[0051](ii) Add 30g of azobisisobutyronitrile to 500g of 4,4,5,5,5-pentafluoro-2-iodo-1-pentanol, slowly add 50g of palladium acetate, and control the reaction temperature to 60℃~ 70°C, react for 3h-4h. After the reaction was completed, the pentafluoropentanol product was obtained by filtration, with a quality of 260 g. The product was purified by distillation to obtain a pentafluoropentanol product with a purity greater than 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com