Method and system for performing simultaneous desulfurization, denitrification and demercuration by ozone in combination with microwave-excited magnetically-separable catalyst

A technology of desulfurization, denitrification, mercury removal and magnetic separation, applied in the field of flue gas purification, can solve problems such as hindering the transmission of ultraviolet light, difficulty in large-scale reaction devices, and restrictions on the industrial application of photochemical removal systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

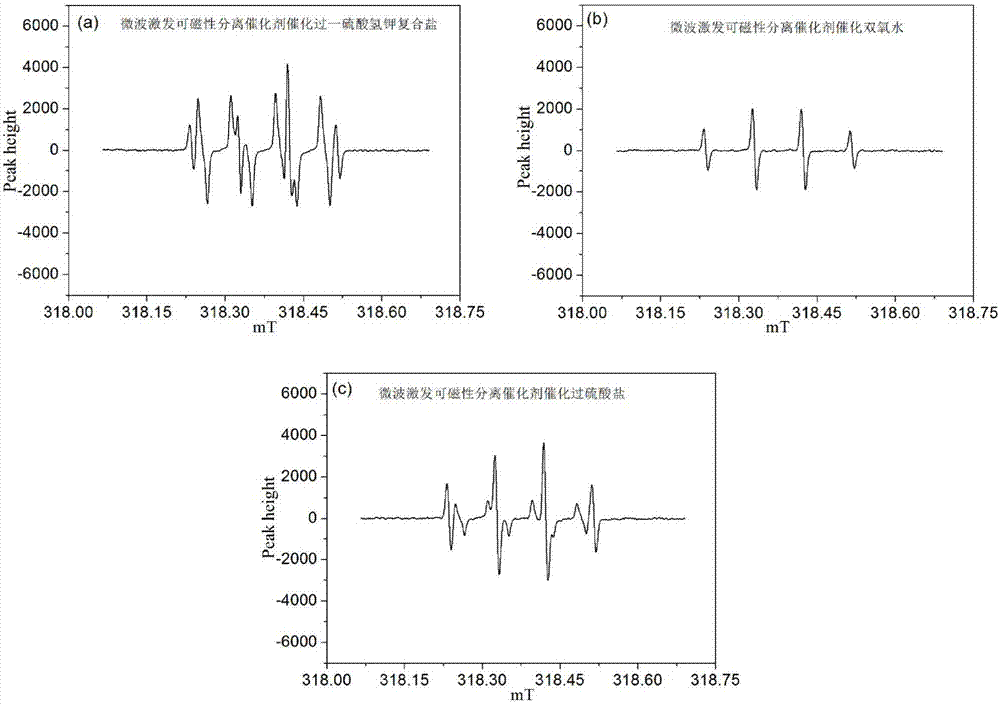

[0101] Example 1. SO in flue gas 2 ﹑NO and Hg 0 Concentrations are 2000ppm, 300ppm and 50μg / m 3 , the flue gas temperature is 40°C, the ozone concentration is 80ppm, the molar concentration of potassium hydrogen persulfate compound salt is 0.3mol / L, the pH of the solution is 3.8, the catalyst CoFe 2 o 4 The dosage is 0.3kg per cubic meter, and the microwave radiation power density is 300W / m 3 , the liquid-gas ratio is 3L / m 3 . The results of the small test are: SO in flue gas 2 ﹑NO and Hg 0 The simultaneous removal efficiencies can reach 82.2%, 55.2% and 83.1%, respectively.

Embodiment 2

[0102] Example 2. SO in flue gas 2 ﹑NO and Hg 0 Concentrations are 2000ppm, 300ppm and 50μg / m 3 , the flue gas temperature is 40°C, the ozone concentration is 120ppm, the molar concentration of potassium hydrogen persulfate compound salt is 0.6mol / L, the pH of the solution is 3.8, the catalyst CoFe 2 o 4 The dosage is 0.4kg per cubic meter, and the microwave radiation power density is 600W / m 3 , the liquid-gas ratio is 3L / m 3 . The results of the small test are: SO in flue gas 2 ﹑NO and Hg 0 The simultaneous removal efficiencies can reach 89.2%, 65.2% and 95.1%, respectively.

Embodiment 3

[0103] Example 3. SO in flue gas 2 ﹑NO and Hg 0 Concentrations are 2000ppm, 300ppm and 50μg / m 3 , the flue gas temperature is 40°C, the ozone concentration is 160ppm, the molar concentration of potassium hydrogen persulfate compound salt is 1.0mol / L, the pH of the solution is 3.8, the catalyst CoFe 2 o 4 The dosage is 0.6kg per cubic meter, and the microwave radiation power density is 800W / m 3 , the liquid-gas ratio is 3L / m 3 . The results of the small test are: SO in flue gas 2 ﹑NO and Hg 0 The simultaneous removal efficiencies can reach 100%, 92.2% and 100%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com