Melt-blown fiber/nano fiber/glass fiber composite filter material and its preparation

A melt-blown fiber and glass fiber technology is applied in the field of melt-blown fiber/nanofiber/glass fiber composite filter material and its preparation, which can solve the problems of performance degradation and nanofiber functional layer structure damage, and achieve long service life and fiber. The effect of small diameter and small pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

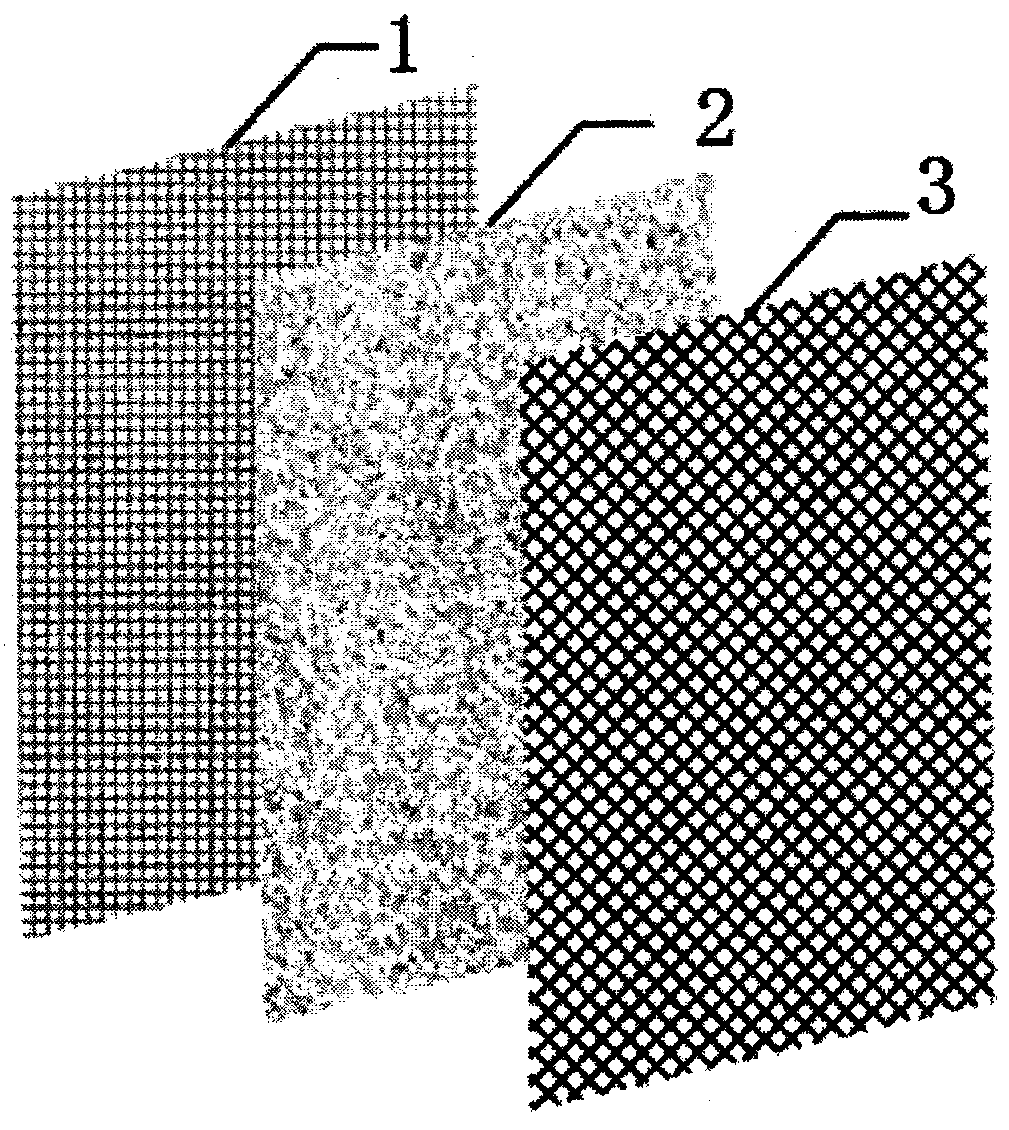

[0035] Such as figure 1 As shown, a kind of meltblown fiber / nanofiber / glass fiber composite filter material comprises a glass fiber substrate 1, a nanofiber layer 2 and a meltblown fiber cover layer 3 arranged in sequence from bottom to top, wherein the nano The upper surface of the fiber layer 2 is provided with a fusion point formed by solvent electrostatic spraying technology, and the melt-blown fiber covering layer 3 is bonded to the nanofiber layer 2 by means of the fusion point by means of a composite method of thermal bonding.

[0036] The preparation method of described melt-blown fiber / nano fiber / glass fiber composite filter material, concrete steps are:

[0037] (1) nanofibers are deposited on the gauze substrate 1 to form a nanofiber layer 2, the specific operations are as follows:

[0038] The first step: dissolving polystyrene particles (80,000 molecular weight) in N,N-dimethylformamide, placing the solution on a magnetic stirrer and stirring for 10 hours to form ...

Embodiment 2

[0044] Such as figure 1 As shown, a kind of meltblown fiber / nanofiber / glass fiber composite filter material comprises a glass fiber substrate 1, a nanofiber layer 2 and a meltblown fiber cover layer 3 arranged in sequence from bottom to top, wherein the nanofiber The upper surface of the fiber layer 2 is provided with a fusion point formed by solvent electrostatic spraying technology, and the melt-blown fiber covering layer 3 is bonded to the nanofiber layer 2 by means of the fusion point by means of a composite method of thermal bonding.

[0045] The preparation method of described melt-blown fiber / nano fiber / glass fiber composite filter material, concrete steps are:

[0046] (1) nanofibers are deposited on the gauze substrate 1 to form a nanofiber layer 2, the specific operations are as follows:

[0047] The first step: dissolving polystyrene particles (molecular weight 100,000) in N,N-dimethylformamide, placing the solution on a magnetic stirrer and stirring for 10 hours ...

Embodiment 3

[0053] Such as figure 1 As shown, a kind of meltblown fiber / nanofiber / glass fiber composite filter material comprises a glass fiber substrate 1, a nanofiber layer 2 and a meltblown fiber cover layer 3 arranged in sequence from bottom to top, wherein the nanofiber The upper surface of the fiber layer 2 is provided with a fusion point formed by solvent electrostatic spraying technology, and the melt-blown fiber covering layer 3 is bonded to the nanofiber layer 2 by means of the fusion point by means of a composite method of thermal bonding.

[0054] The preparation method of described melt-blown fiber / nano fiber / glass fiber composite filter material, concrete steps are:

[0055] (1) nanofibers are deposited on the gauze substrate 1 to form a nanofiber layer 2, the specific operations are as follows:

[0056] The first step: dissolving polystyrene particles (molecular weight: 150,000) in N,N-dimethylformamide, placing the solution on a magnetic stirrer and stirring for 10 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com