Method for lipase-catalyzed online synthesis of N-(5-vinyl ester valeryl)mexiletine

A technology for vinyl ester valeryl and mexiletine, which is applied in the field of lipase catalyzed on-line controllable and selective synthesis of N-mexiletine, can solve the problems of low bioavailability, short half-life, long reaction time and the like, and shorten the reaction time. Time, high conversion and selectivity, effect of reducing reaction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

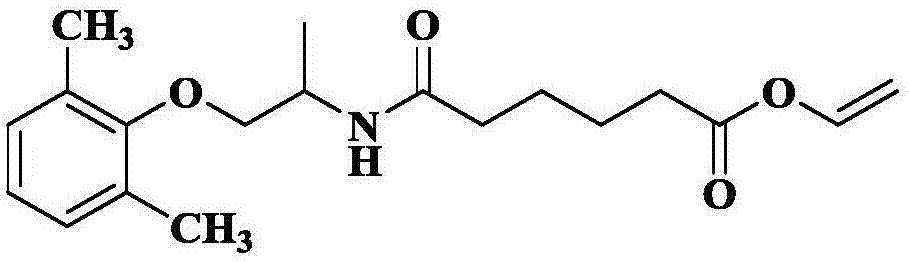

[0028] Embodiment 1: the synthesis of N-(5-vinyl pentanoyl) mexiletine

[0029]

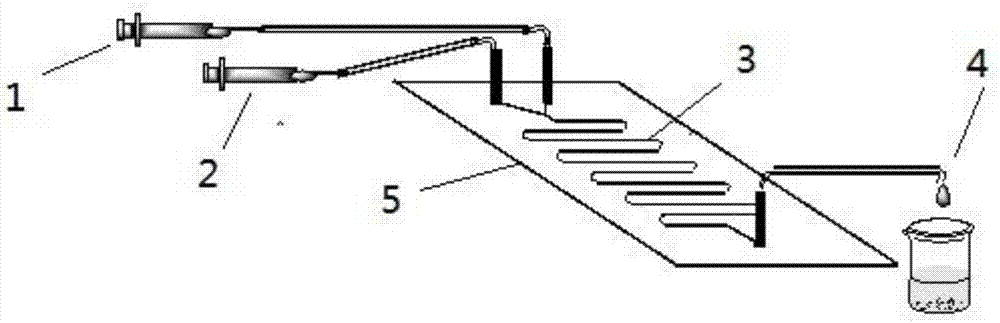

[0030] device referencefigure 1 : Mexiletine (1.0mmol) was dissolved in 2.50mL DMSO and 7.50mL tert-amyl alcohol, divinyl adipate (4.0mmol) was dissolved in 2.50mL DMSO and 7.50mL tert-amyl alcohol, and then filled into 10mL syringes in spare. 0.87g of lipase Lipozyme TLIM was evenly filled in the reaction channel, and driven by the PD 1200 syringe pump, the two reaction solutions were separated at 10.4 μL min -1 The flow rate enters the reaction channel through the "Y" joint for reaction, and the temperature of the reactor is controlled at 50 ° C by a water bath thermostat. The reaction solution flows continuously in the reaction channel for 30 minutes, and the reaction results are tracked and detected by thin-layer chromatography TLC.

[0031] The reaction solution was collected online by the product collector, the solvent was distilled off under reduced pressure, and the column was wet-pac...

Embodiment 2-7

[0036] Change the volume ratio of the organic solvent (DMSO: tert-amyl alcohol) in the microfluidic channel reactor, and control the temperature to 50°C. Others are the same as in Example 1. The reaction results are shown in Table 1:

[0037] Table 1: Influence of the reaction medium on the reaction

[0038] Example

[0039] The results in Table 1 show that when the flow rate is 10.4 μL min -1 , the reaction time is 30min, the reaction temperature is 50°C, the ratio of the amount of reactant mexiletine to divinyl adipate is 1:2, and the conversion rate varies with the organic solvent (DMSO: tert-amyl alcohol) in the reaction system. ) volume ratio increases and increases, and when DMSO: tert-amyl alcohol volume ratio is 1:3, reaction transformation efficiency is optimal, is 90%, if continue to increase the amount of tert-amyl alcohol in the reaction system now, will cause If the reactants are not completely dissolved, the conversion rate of the reaction will decreas...

Embodiment 8-12

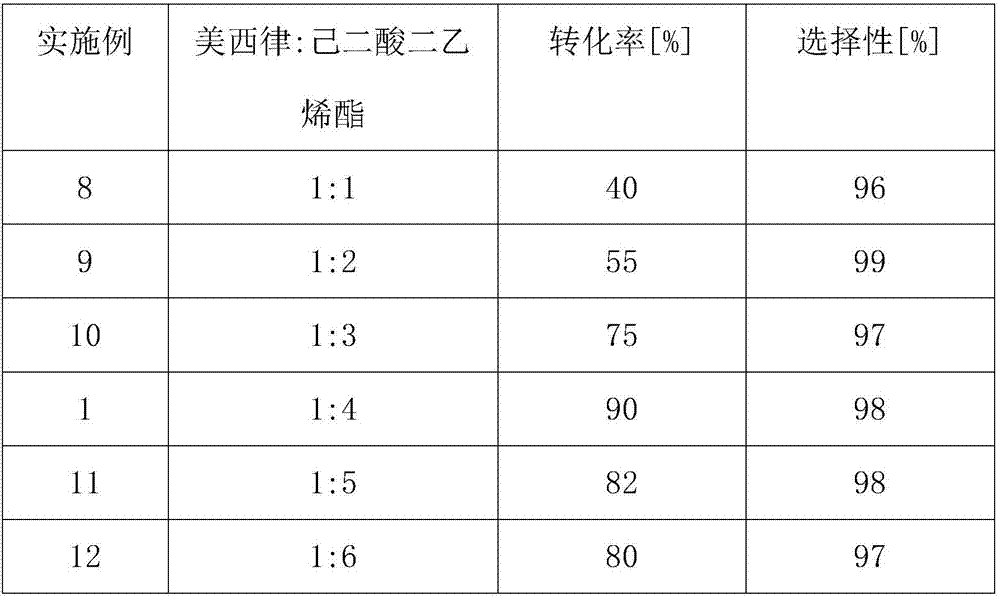

[0041] Change the ratio of the amount of mexiletine to the substrate substance of divinyl adipate in the microfluidic microchannel reactor, and control the temperature at 50°C. Others are the same as in Example 1. The results are shown in Table 2:

[0042] Table 2: The impact of the ratio of the amount of mexiletine and divinyl adipate substrate substance on the reaction

[0043]

[0044] The results in Table 2 show that when the flow rate is 10.4 μL min -1 , the reaction time is 30min, the reaction temperature is 50 DEG C, the organic solvent DMSO in the reactor: tert-amyl alcohol volume ratio is 1:3, along with the increase of the reactant divinyl adipate, the conversion rate of the reaction also increases. Along with increasing, when the ratio of the amount of substrate substance is 1:4, the conversion rate of reaction is optimal, so the ratio of the amount of optimum substrate substance in the microfluidic microchannel reactor of the present invention is 1:4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com