Martensitic stainless steel with high low-temperature impact

A martensitic stainless steel and low-temperature impact resistance technology, applied in the field of stainless steel, can solve the problems of low impact toughness and low comprehensive mechanical properties, and achieve the effects of improving impact toughness, improving comprehensive mechanical properties, and simple and convenient processing technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1, a martensitic stainless steel with strong low-temperature impact, including the following components in mass percentage, C: 0.08%, Si: 0.01%, Mn: 0.01%, P: 0.01%, S: 0.01%, Cr: 11.5%, Ni: 0.8%, Mo: 0.2%, the balance is Fe and other impurities. The process steps of the quenching and tempering heat treatment process include: step one, quenching, heating the steel to be treated in a vertical heating furnace to 920°C and holding it for a period of time, and then rapidly cooling; step two, tempering, the quenched steel The vertical heating furnace is heated to 570℃ and kept for a period of time and then quickly cooled; step three, stress relief annealing, rough turning the tempered steel, and perform stress relief process, and then obtain the required heat-treated stainless steel material. The heating rate of the steel to be treated in the first step is less than 120°C / h, and the heating rate of the steel during tempering in the second step is less than 80°C / h.

Embodiment 2

[0018] Embodiment 2, a martensitic stainless steel with strong low-temperature impact, including the following components in mass percentages, C: 0.15%, Si: 1.0%, Mn: 1.0%, P: 0.04%, S: 0.03%, Cr: 13.5%, Ni: 1.2%, Mo: 0.4%, the balance is Fe and other impurities. The process steps of the quenching and tempering heat treatment process include: step one, quenching, heating the steel to be treated in a vertical heating furnace to 1000°C and holding it for a period of time, and then quickly cooling; step two, tempering, the quenched steel The vertical heating furnace is heated to 650°C and kept for a period of time and then quickly cooled; step three, stress relief annealing, rough turning the tempered steel, and performing stress relief procedures, and then obtain the required heat-treated stainless steel material. The heating rate of the steel to be treated in the first step is less than 120°C / h, and the heating rate of the steel during tempering in the second step is less than 8...

Embodiment 3

[0019] Example 3 includes the following components by mass percentage, C: 0.114%, Si: 0.34%, Mn: 0.42%, P: 0.021%, S: 0.01%, Cr: 12.01%, Ni: 0.84%, Mo: 0.22 %, the balance is Fe and other impurities. The process steps of the quenching and tempering heat treatment process include: step one, quenching, heating the steel to be treated in a vertical heating furnace to 970°C and holding it for a period of time, and then rapidly cooling; step two, tempering, the quenched steel The vertical heating furnace is heated to 605°C and kept for a period of time and then rapidly cooled; step three, stress relief annealing, rough turning the tempered steel, and perform stress relief procedures, and then obtain the required heat-treated stainless steel material. The heating rate of the steel to be treated in the first step is less than 120°C / h, and the heating rate of the steel during tempering in the second step is less than 80°C / h.

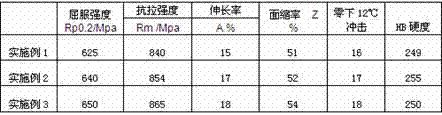

[0020] The various mechanical performance parameters of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com