Additive manufacturing method

A technology of additive manufacturing and powder, which is applied in the direction of additive manufacturing, additive processing, and improvement of process efficiency. It can solve the problems of difficult powder preparation and low yield, and achieve the effect of forming accuracy and forming quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Example 1 of the present invention uses the additive manufacturing method of the present invention to prepare a denture. include:

[0056] In the slicing step, the designed virtual denture component model is sliced discretely, and the slice thickness is 30 μm.

[0057] In the path planning step, the laser scanning path is planned according to the slice profile information obtained from the slice. The planned scanning path is scanned in a nine-square grid, and the scanning angle is deflected during layer-by-layer scanning, and the deflection angle is 37°.

[0058] In the preheating step, the substrate is preheated to 100 °C.

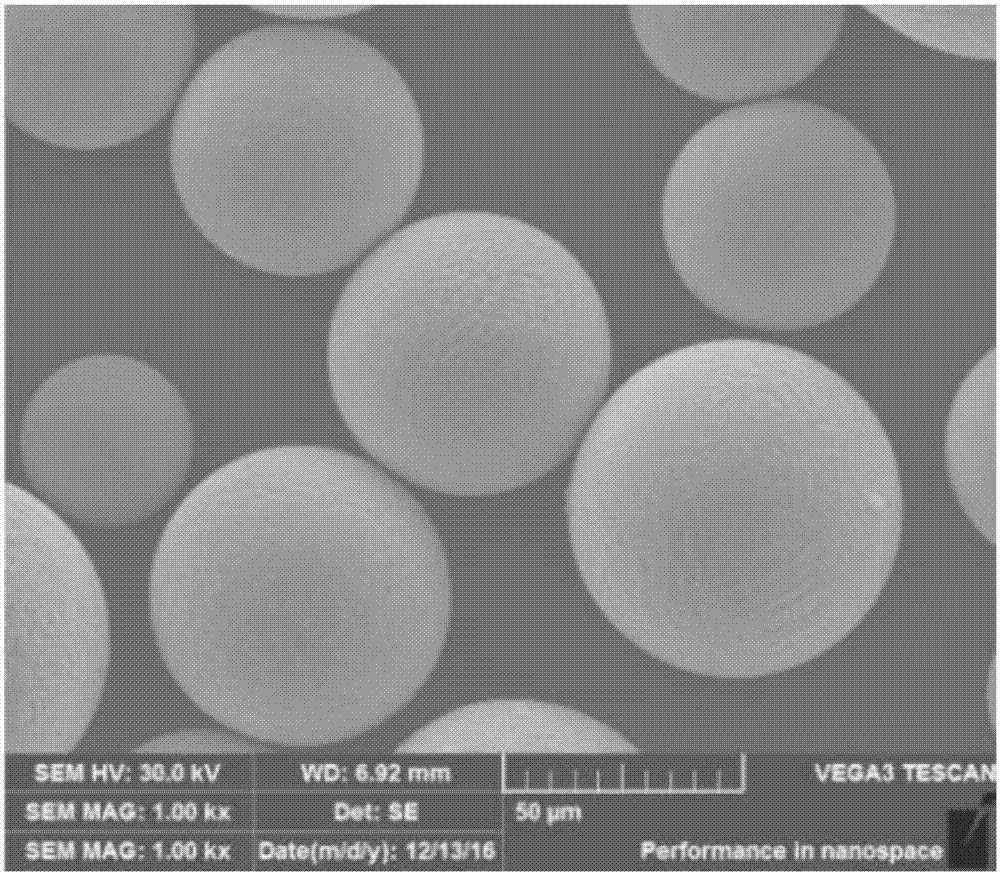

[0059] In the powder spreading step, a layer of powder with a thickness of 30 μm is evenly laid on the substrate, and the powder used is cobalt-chromium-molybdenum alloy powder, and the fluidity is ≤24s / 50g. Wherein, the weight ratio of the fine particle powder with a particle size range of 0 μm to 43 μm and the coarse particle powder with a pa...

Embodiment 2

[0065] Example 2 of the present invention uses the additive manufacturing method of the present invention to prepare an aviation component. include:

[0066] In the slicing step, the designed virtual aviation component model is sliced discretely, and the slice thickness is 25 μm.

[0067] In the path planning step, the laser scanning path is planned according to the slice profile information obtained from the slice. The planned scanning path is scanned in a nine-square grid, and the scanning angle is deflected during layer-by-layer scanning, and the deflection angle is 37°.

[0068] Preheating step: Preheat the substrate to 200°C.

[0069] In the powder spreading step, a layer of powder with a thickness of 30 μm is evenly laid on the substrate, and the powder used is cobalt-chromium-molybdenum alloy powder, and the fluidity is ≤24s / 50g. Wherein, the weight ratio of the fine particle powder with a particle size range of 0 μm to 43 μm and the coarse particle powder with a pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com