Antibacterial alginate composite functional dressing and preparation method thereof

A composite function, alginate technology, applied in the field of medical biopolymer materials, can solve problems such as limited wound healing ability, achieve the effects of good biocompatibility and biosafety, small medicinal amount, and low cost input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1 Dissolve sodium alginate and sodium carboxymethylcellulose in purified water at a mass ratio of 9:1, stir mechanically at a stirring speed of 800 rpm / min, and dissolve at a temperature of 40°C. After the solution is completely dissolved and forms a viscous solution, use After degassing under reduced pressure and filtered under reduced pressure, the spinning stock solution is formed, which will be extruded through the spinneret hole into a coagulation bath containing calcium ions. The calcium ion coagulation bath is an aqueous or alcohol solution of 10 wt.% calcium salt, and the spinning The speed is 20m / min to form solid alginate fiber filaments. The filaments are stretched, washed with water, dehydrated and dried, crimped to form fibers.

[0028] 2 Prepare a 2 vt.% acetic acid solution, dissolve an appropriate amount of chitosan in the acetic acid solution to prepare a 0.04 g / ml chitosan solution, pour the chitosan solution into the dipping tank, and immerse the guid...

Embodiment 2

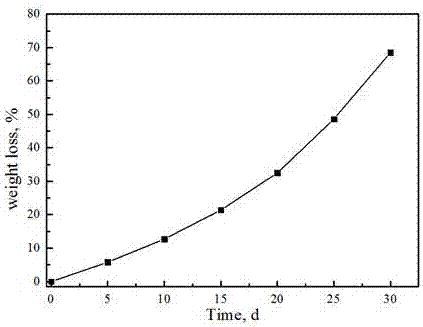

[0032] An in vitro degradation test was carried out on the antibacterial alginate composite functional dressing prepared in Example 1.

[0033] Simulated body fluid preparation: The formula of simulated body fluid is: 8.035g NaCl; 0.355g NaHCO3; 0.225g KCl; 0.231g K2HPO4 3H2O; 0.311g MgCl2 3H2O; 1~5ml 1.0M HCl. The temperature of the prepared solution needs to be kept at 36.5±1.5°C. During the preparation, the reagents should be added in order to adjust the pH to 7.40.

[0034]In vitro degradation test: Take a 10 cm × 10 cm alginate dressing, dry it to constant weight, and weigh it. Place the dried dressing in a 250mL Erlenmeyer flask, add 150mL simulated body fluid, seal it and sterilize it at 121°C for 20min. After the sterilization was completed, the Erlenmeyer flask was cooled to room temperature, and then placed in a shaker at 37°C to simulate degradation. Sampling was carried out at the following time points (1, 5, 10, 15, 20, 25 and 30d), and 3 parallel samples were ...

Embodiment 3

[0039] The antibacterial alginate composite functional dressing prepared in Example 1 was subjected to a rabbit ear artery hemostasis test.

[0040] Select healthy male New Zealand rabbits and divide them into medical gauze group and alginate dressing group. The ears of New Zealand rabbits were depilated and disinfected, and anesthetized by slowly injecting 3% sodium pentobarbital into the marginal ear vein of the rabbits at a rate of 30 mg / kg body weight. On the outer third of the ear, cut a wound with a length of 1 cm with a sterilized scalpel, so that the central aorta of the ear was incised but not penetrated. After 3 s, the wound was filled with blood and immediately covered with a pre-weighed hemostatic material ( 2 cm×3 cm), and covered with weighed medical gauze, 50 g weight for oppression to stop bleeding. Start timing while covering the dressing, and use the weighed cotton to absorb the bleeding around it, and time it every 10 s. If the wound does not ooze within 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com