Microcapsule technology-based cellulase and enzyme treatment process thereof on cotton fabric

A microcapsule technology and cellulase technology, which is applied in the field of cellulase and its enzymatic treatment process on cotton fabrics, can solve the problems of small binding force, etc., achieve improved adsorption capacity, good comprehensive performance, and omit the post-finishing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

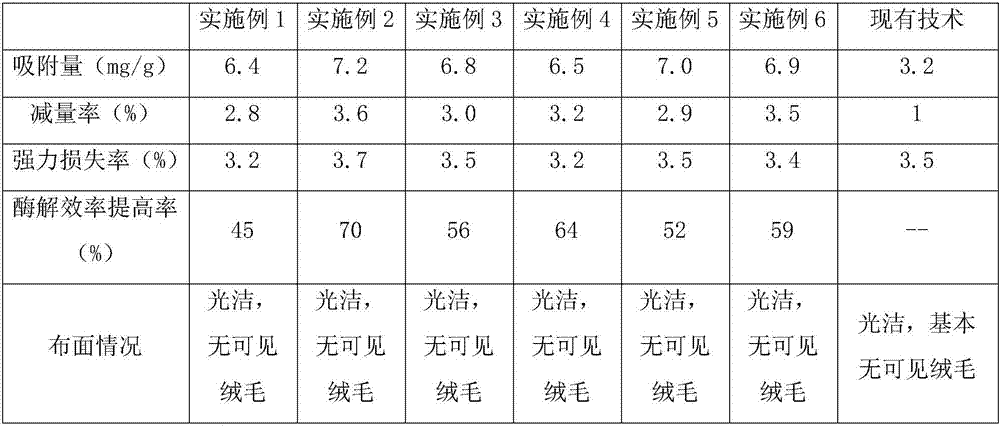

Examples

Embodiment 1

[0025] (1) Add neutral cellulase to a phosphate buffer solution with a pH of 7 for extraction and dissolution, then add cationic guar gum solution and polyethylene glycol with a molecular weight of 1000, stir to make it evenly mixed, and form a pretreatment solution, wherein the content of neutral cellulase in the pretreatment solution is 5 mg / mL, the content of cationic guar gum is 0.5%, and the content of polyethylene glycol is 0.2%.

[0026] (2) Drop the pretreatment solution into a 10 mg / mL sodium tripolyphosphate aqueous solution through a pulse electric field generator, solidify in the sodium tripolyphosphate aqueous solution for 20 minutes, separate and sieve, and wash with water to obtain a carrier with a particle size of 8-15 μm. Microcapsules of neutral cellulase.

[0027] (3) After the surface of the cotton fabric is treated with alkali, the bath ratio is 1:40, and it is immersed in the aqueous solution of microcapsules loaded with neutral cellulase. The mass ratio...

Embodiment 2

[0030] (1) Add neutral cellulase to a phosphate buffer solution with a pH of 7.5 for extraction and dissolution, then add cationic guar gum solution and polyethylene glycol with a molecular weight of 1000, stir to make it evenly mixed, and form a pretreatment solution, wherein the content of neutral cellulase in the pretreatment solution is 10 mg / mL, the content of cationic guar gum is 1%, and the content of polyethylene glycol is 0.3%.

[0031] (2) Drop the pretreatment solution into a 10 mg / mL sodium tripolyphosphate aqueous solution through a pulse electric field generating device, solidify in the sodium tripolyphosphate aqueous solution for 30 minutes, separate, sieve, and wash with water to obtain a carrier with a particle size of 8-15 μm. Microcapsules of neutral cellulase.

[0032] (3) After the surface of the cotton fabric is treated with plasma activation, the bath ratio is 1:40, immersed in the aqueous solution of microcapsules loaded with neutral cellulase, accordin...

Embodiment 3

[0035] (1) Add neutral cellulase to a phosphate buffer solution with a pH of 7.2 for extraction and dissolution, then add cationic guar gum solution and polyethylene glycol with a molecular weight of 1000, stir to make it evenly mixed, and form a pretreatment solution, wherein the content of neutral cellulase in the pretreatment solution is 6 mg / mL, the content of cationic guar gum is 0.7%, and the content of polyethylene glycol is 0.25%.

[0036] (2) Drop the pretreatment solution into a 10 mg / mL sodium tripolyphosphate aqueous solution through a pulse electric field generating device, solidify in the sodium tripolyphosphate aqueous solution for 25 minutes, separate and sieve, and wash with water to obtain a carrier with a particle size of 8-15 μm. Microcapsules of neutral cellulase.

[0037](3) After the surface of the cotton fabric is treated with alkali or plasma activation, the bath ratio is 1:40, immersed in the aqueous solution of microcapsules loaded with neutral cellu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com