Lead-free ceramic material with high energy storage density and high energy storage efficiency and preparation method thereof

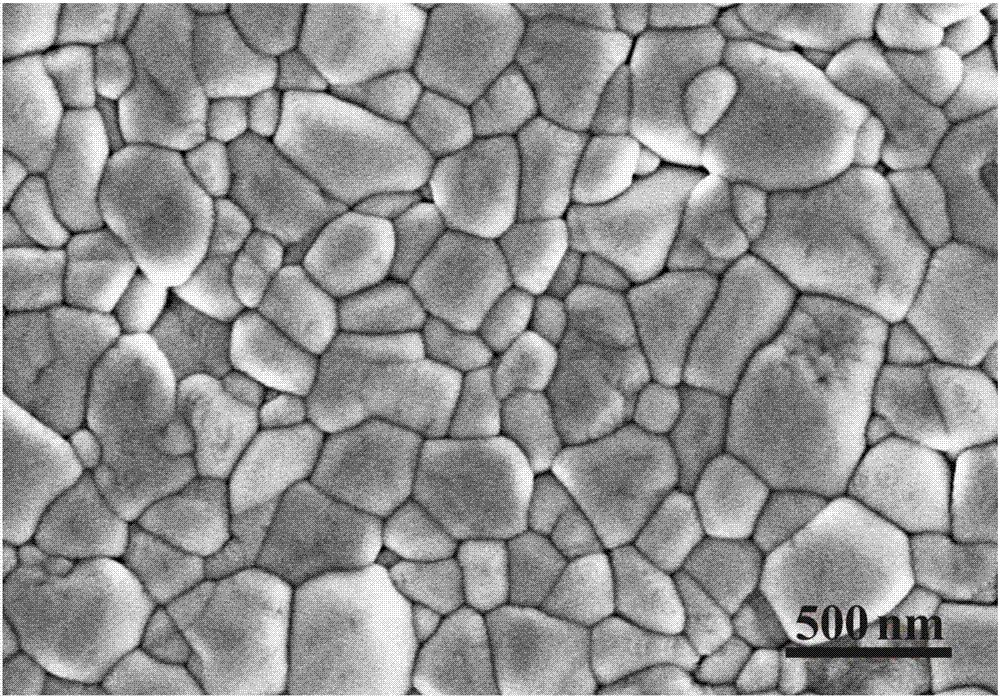

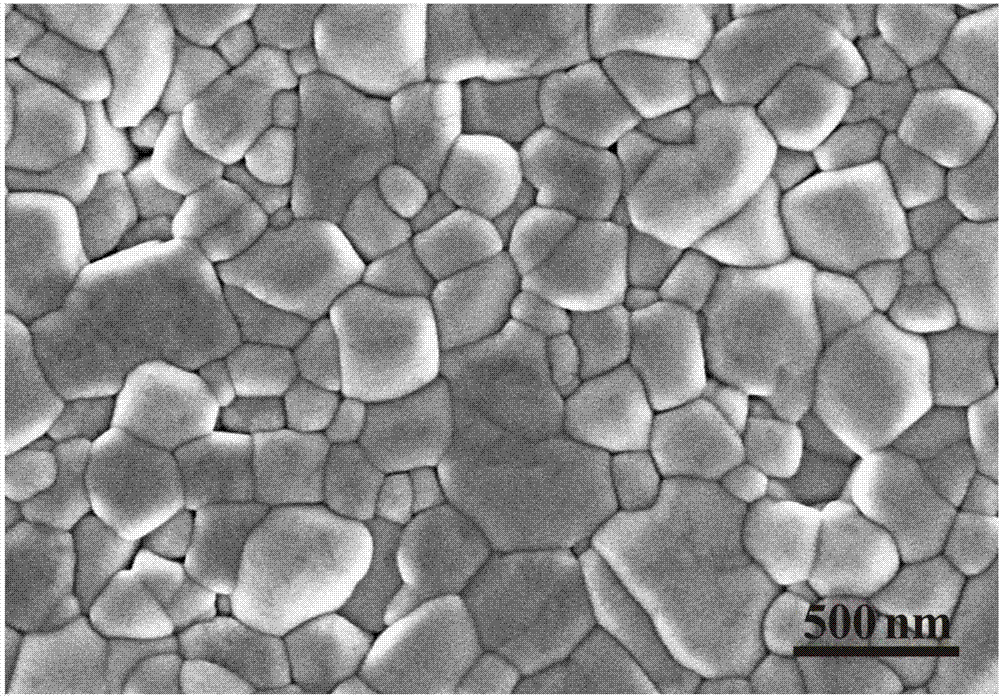

A high energy storage density, ceramic material technology, applied in the field of lead-free ceramic materials and its preparation, can solve the problems of uneven grain size distribution, low energy storage density, low energy storage efficiency, etc., and achieve uniform grain size distribution , Improve the energy storage density, improve the effect of energy storage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the lead-free ceramic material with high energy storage density and high energy storage efficiency of the present invention comprises the following steps:

[0032] (1) According to the chemical formula Ba 0.4 Sr 0.6 TiO 3 SrTiO 3 Nano powder (3 Nanopowder (0.4 Sr 0.6 TiO 3 Powder. and SrTiO 3 Nano powder and BaTiO 3 Nano powders were purchased from Beijing Deke Daojin Technology Co., Ltd.

[0033] (2) According to Bi 2 o 3 :B 2 o 3 : SiO 2 = 13:4:3 molar ratio to weigh Bi in turn 2 o 3 , B 2 o 3 and SiO 2 , mixed evenly through ball milling, and the ball milling medium is absolute ethanol, the ball milling time is 12-16 hours, then the temperature is raised to 1200-1300°C and kept for 1-2 hours to obtain a high-temperature melt, and then the obtained high-temperature glass melt is quickly Pour into deionized water to form broken small glass pieces, and finally grind the formed broken small glass pieces to obtain Bi 2 o 3 -B ...

Embodiment 1

[0044] The chemical formula of lead-free ceramic materials with high energy storage density and high energy storage efficiency is: Ba 0.4 Sr 0.6 TiO 3 -x(Bi 2 o 3 -B 2 o 3 -SiO 2 ), where x represents Bi 2 o 3 -B 2 o 3 -SiO 2 The mass percentage of x=3wt%.

[0045] The preparation method of the above-mentioned lead-free ceramic material with high energy storage density and high energy storage efficiency comprises the following steps:

[0046] (1) According to the chemical formula Ba 0.4 Sr 0.6 TiO 3 SrTiO 3 Nano powder (3 Nano powder (0.4 Sr 0.6 TiO 3 Powder.

[0047] (2) According to Bi 2 o 3 :B 2 o 3 : SiO 2 = 13:4:3 molar ratio to weigh Bi in turn 2 o 3 , B 2 o 3 and SiO 2 The raw materials are mixed evenly by ball milling process and heated to 1200°C for 2 hours to obtain a high-temperature glass melt, and then the obtained high-temperature glass melt is quickly poured into deionized water to form broken glass pieces, and finally the formed brok...

Embodiment 2

[0055] The chemical formula of lead-free ceramic materials with high energy storage density and high energy storage efficiency is: Ba 0.4 Sr 0.6 TiO 3 -x(Bi 2 o 3 -B 2 o 3 -SiO 2 ), where x represents Bi 2 o 3 -B 2 o 3 -SiO 2 The mass percent of x=6wt%.

[0056]The preparation method of the above-mentioned lead-free ceramic material with high energy storage density and high energy storage efficiency comprises the following steps:

[0057] (1) According to the chemical formula Ba 0.4 Sr 0.6 TiO 3 SrTiO 3 Nano powder (3 Nano powder (0.4 Sr 0.6 TiO 3 Powder.

[0058] (2) According to Bi 2 o 3 :B 2 o 3 : SiO 2 = 13:4:3 molar ratio to weigh Bi in turn 2 o 3 , B 2 o 3 and SiO 2 The raw materials are mixed evenly by ball milling process and then heated to 1270°C for 1.5 hours to obtain a high-temperature glass melt, and then the obtained high-temperature glass melt is quickly poured into deionized water to form broken glass pieces, and finally the formed b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com