Nano-fiber and micro-fiber composite anti-haze gauze mask

A technology of microfibers and nanofibers, applied in protective clothing, clothing, clothing, etc., can solve the problems of poor interception effect of inhalable particulate matter such as PM2.5, and achieve the effect of simple preparation method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

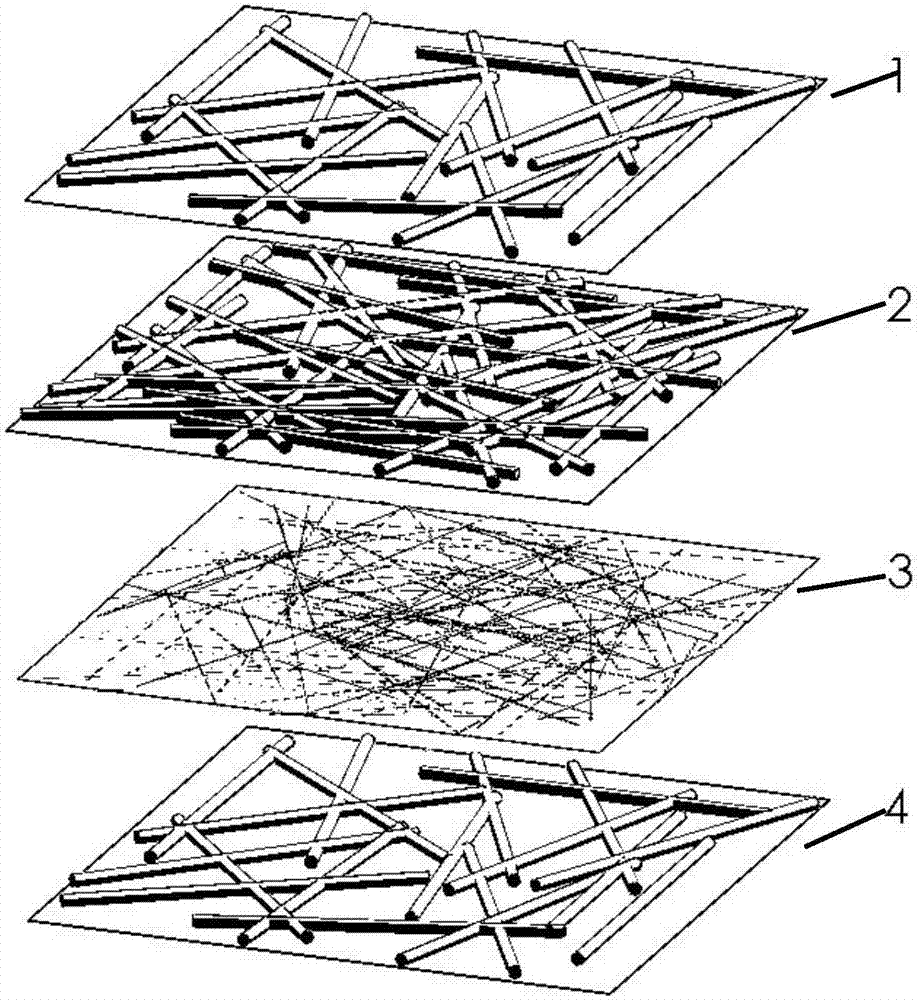

[0038] In this embodiment, the helical needle-free electrospinning technology is used to prepare an aqueous solution of polyvinyl alcohol (PVA, with an average molecular weight of 146,000 to 186,000, 96% hydrolyzed, Sigma-Aldrich) with a concentration of 8%, and the polyvinyl alcohol is injected into the reservoir first. In the liquid tank, set the spinning voltage to 75kV, the spinning distance to 20cm, the spinning head speed to 5rpm, the fiber speed of the stainless steel woven mesh curtain collector to 10m / min, and the spinning time to 1.5min. The base fabric is spunbonded nonwoven fabric for air filtration. Using 1 nanofiber layer 3 ( figure 1 Middle layer 3) and 2 layers of spunbond nonwovens 1, 4 ( figure 1 1st layer, 4th layer), 1 layer of melt-blown nonwoven fabric for air filtration 2 ( figure 1 The second layer in the mask) is composited into a mask (a total of 4 layers use 1 nanofiber layer). After testing, the composite mask as an air filter material has a rete...

Embodiment 2

[0040] This embodiment uses spiral needle-free electrospinning technology to prepare an aqueous solution of polyvinyl alcohol (PVA, with an average molecular weight of 146,000 to 186,000, 96% hydrolyzed, Sigma-Aldrich) with a concentration of 8%. First, the polyvinyl alcohol is injected into the stock solution In the groove, the spinning voltage is set to be 75kV, the spinning distance is 20cm, the spinning head speed is 5rpm, the fiber speed of the stainless steel woven mesh curtain collector is 10m / min, and the spinning time is 2min. The base fabric is spunbonded nonwoven fabric for air filtration. The nanofiber layer on the nonwoven fabric ( figure 1 3rd layer) and 2 layers of spunlace nonwovens ( figure 1 1st layer, 4th layer), 1 layer of melt-blown nonwoven fabric for air filtration ( figure 1 Middle ground 2 layers) compound to make a mask. Reference for the compound form of non-woven fabrics in masks figure 1 . After testing, the composite mask as an air filter mat...

Embodiment 3

[0042] Polyvinylidene fluoride (PVDF, average molecular weight 275,000, Sigma-Aldrich) was dissolved in DMF / acetone (volume ratio 4 / 6) mixed solvent to prepare a spinning solution with a solubility of 16% by weight.

[0043] Scatter tourmaline fraction (5% by weight) with nanometer particle size into the prepared electrospinning solution.

[0044] The obtained electrospinning solution is poured into the liquid storage tank, and the spiral needle-free electrospinning technology is used to produce tourmaline / PVDF nanofibers. The spinning voltage is set to 75kV, the spinning distance is 20cm, the spinning head speed is 5rpm, and the spinning time 1.5min. The fiber speed of the stainless steel woven mesh curtain collector is 10m / minn. The base fabric is spunbonded nonwoven fabric for air filtration.

[0045] Fabrication of nanofiber layers and nonwovens by figure 1 Composite preparation mask, nanofiber layer ( figure 1 3rd layer) and 2 layers of spunlace nonwovens ( figure 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber diameter | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com