Preparation method of spherical calcium carbonate

A calcium carbonate, spherical technology, applied in the direction of calcium carbonate/strontium/barium, chemical instruments and methods, calcium/strontium/barium compounds, etc., can solve the problems of high production cost, high price, fast reaction process, etc., and achieve production cost Low cost, cheap raw materials, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

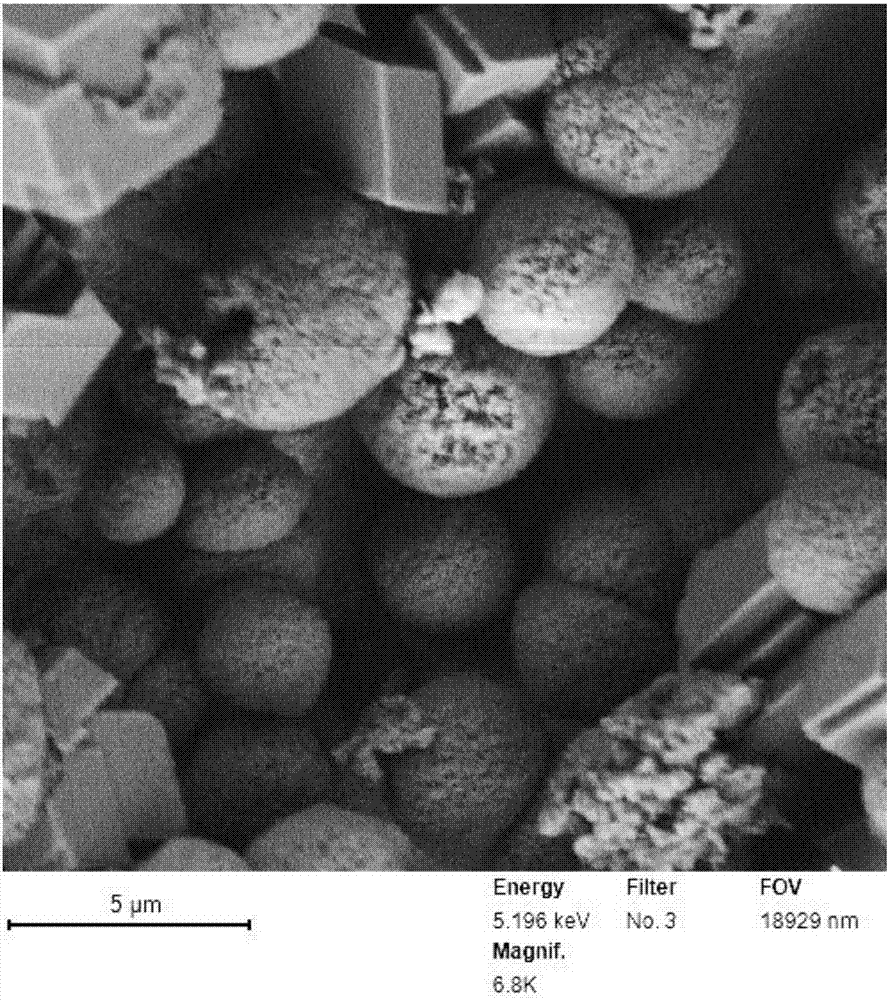

[0024] A preparation method for spherical calcium carbonate, comprising the following steps:

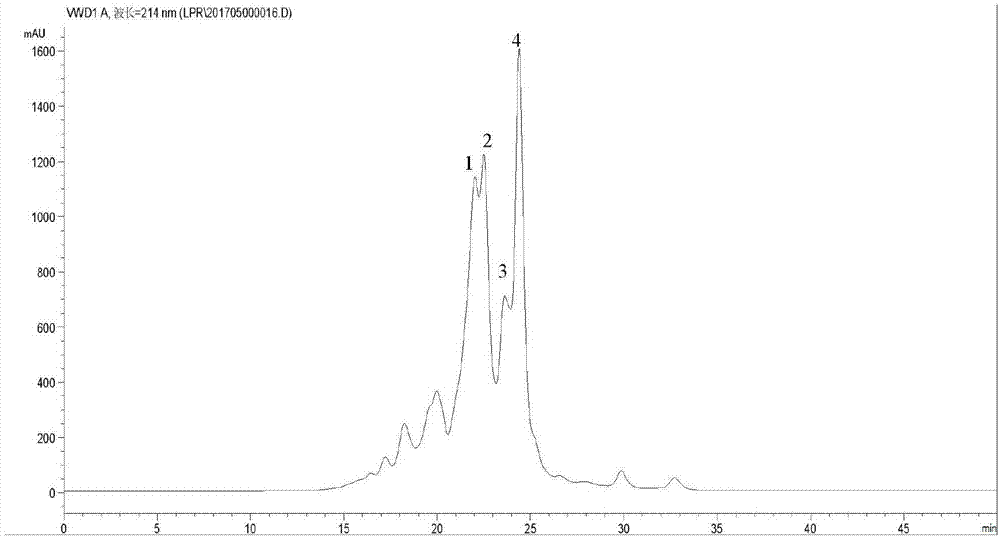

[0025] S1. Remove impurities, degumming, wash and dry the waste silk to obtain degummed silk fibroin, dissolve the degummed silk with a calcium chloride solution with a mass fraction of 40% and filter to obtain a silk fibroin solution, and dialyze the silk fibroin solution to remove chlorine Calcium, and then use 4g serine protease to enzymolyze 100g silk fibroin at 60°C for 3 hours to obtain silk fibroin hydrolyzate, and use a 10,000Da ultrafiltration membrane to collect the permeate with a molecular weight of 360-11808Da. Concentrate by rotary evaporation under the condition of 187Pa, then vacuum freeze-dry for 72h under the condition of temperature of -57°C and pressure of 50Pa to obtain lyophilized powder;

[0026] S2. In parts by weight, add 1 part of calcium oxide to 100 parts of deionized water, stir at a constant temperature of 80 ° C for 4 hours, then pass through a 200-mesh...

Embodiment 2

[0030] S1. Remove impurities, degumming, wash and dry the waste silk to obtain degummed silk fibroin, dissolve the degummed silk with a calcium chloride solution with a mass fraction of 40% and filter to obtain a silk fibroin solution, and dialyze the silk fibroin solution to remove chlorine Calcium, and then use 4g serine protease to enzymolyze 100g silk fibroin at 60°C for 3 hours to obtain silk fibroin hydrolyzate, and use a 10,000Da ultrafiltration membrane to collect the permeate with a molecular weight of 360-11808Da. Concentrate by rotary evaporation under the condition of 187Pa, then vacuum freeze-dry for 72h under the condition of temperature of -57°C and pressure of 50Pa to obtain lyophilized powder;

[0031] S2. In parts by weight, add 1 part of calcium oxide to 100 parts of deionized water, stir at a constant temperature of 80 ° C for 4 hours, then pass through a 200-mesh sieve and seal the filtrate for 24 hours, then dilute the filtrate to a mass fraction of 0.4% ...

Embodiment 3

[0035] S1. Remove impurities, degumming, wash and dry the waste silk to obtain degummed silk fibroin, dissolve the degummed silk with a calcium chloride solution with a mass fraction of 40% and filter to obtain a silk fibroin solution, and dialyze the silk fibroin solution to remove chlorine Calcium, and then use 8g of papain to enzymolyze 100g of silk fibroin at 55°C for 2 hours to obtain a silk fibroin hydrolyzate, and use a 10,000Da ultrafiltration membrane to collect the permeate with a molecular weight of 360-11808Da. The temperature of the permeate is 65°C, Concentrate by rotary evaporation at a pressure of 190Pa, then vacuum freeze-dry at a temperature of -50°C and a pressure of 60Pa for 72 hours to obtain a freeze-dried powder;

[0036] S2. In parts by weight, add 1 part of calcium oxide to 100 parts of deionized water, stir at a constant temperature of 85 ° C for 3 hours, then pass through a 200-mesh sieve and seal the filtrate for 24 hours, then dilute the filtrate to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com