Foam-structure catalyst used in reaction for preparing benzyl alcohol from benzaldehyde through hydrogenation and preparation thereof

A foam structure and catalyst technology, applied in the field of foam structure catalyst and its preparation, can solve the problems of easy wear, complex recovery process, difficult separation of catalyst, etc., and achieve the effects of simple experimental operation process, good catalytic activity, easy separation and recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

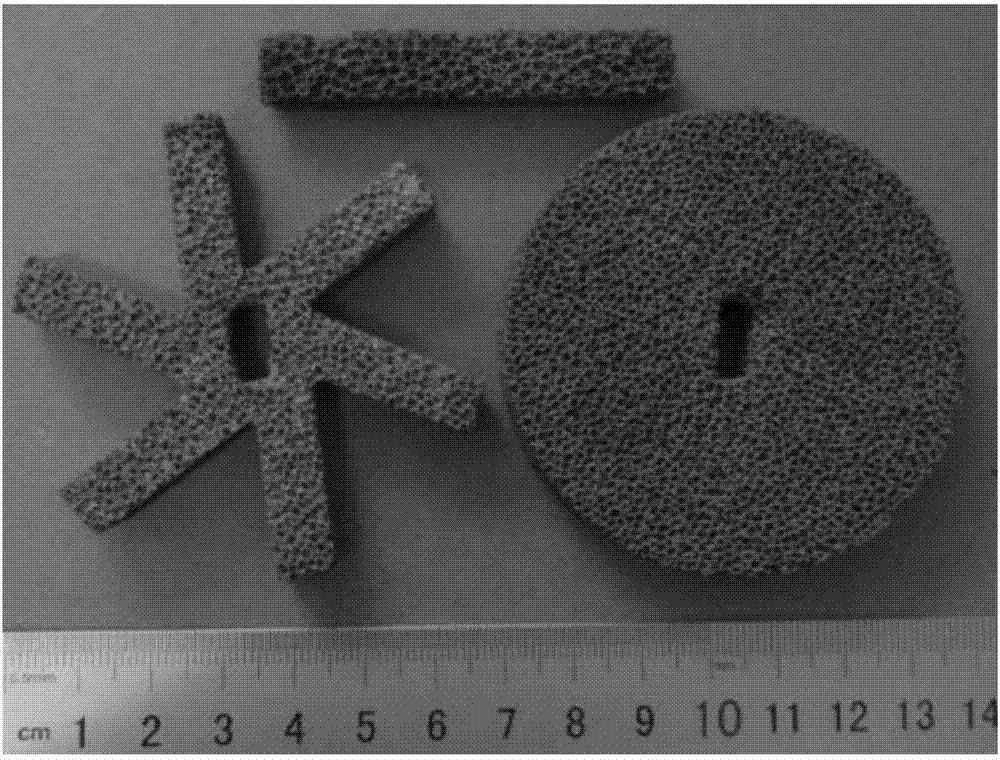

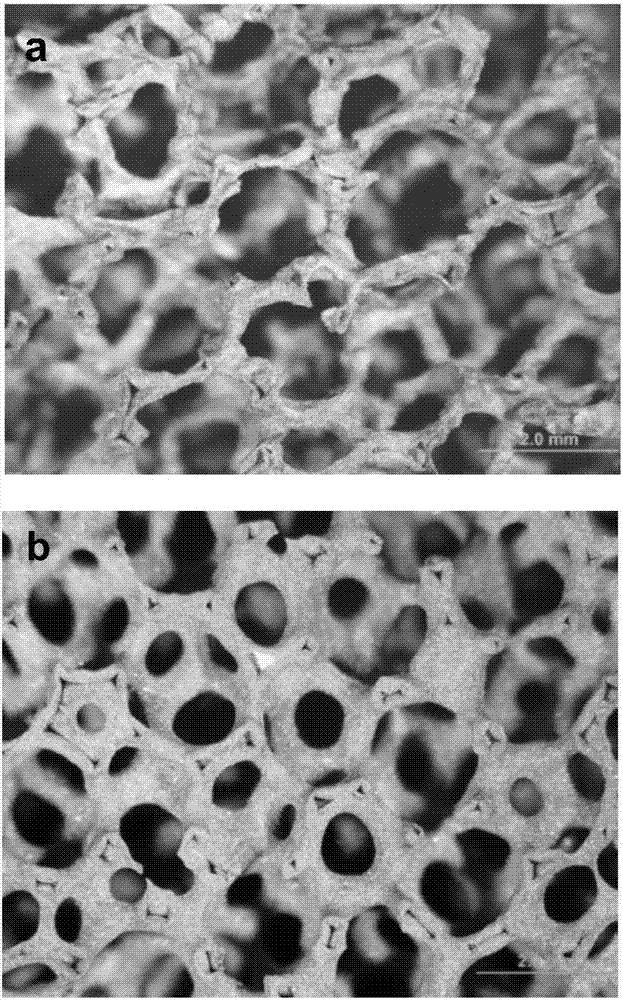

[0023] (1) The preparation method of foamed silicon carbide (the first carrier) is based on the preparation method described in the invention patent with application number CN03134039.3 (publication number CN1600742A). The foamed silicon carbide has a three-dimensional interconnected network porous structure, and the silicon carbide The number of meshes is 2-50PPI, the size range of meshes is 0.5mm-12mm, and the porosity is 20%-90%.

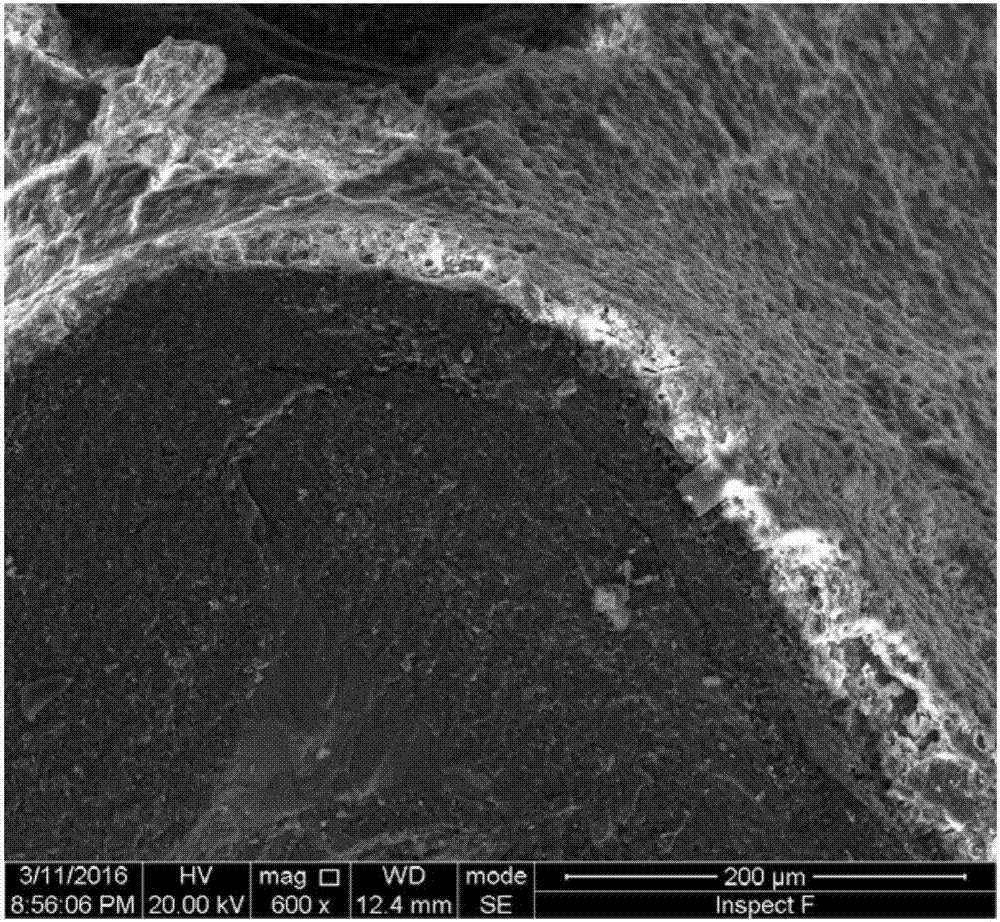

[0024] (2) Prepare a certain concentration of aluminum sol with stable properties, and add an appropriate amount of active γ-Al with a particle size of less than 20 microns in the aluminum sol 2 o 3 Powder, form slurry after ball milling for 6 hours. Among them, the concentration of aluminum sol is 10wt% ~ 30wt%, active γ-Al 2 o 3 The weight ratio of the powder to the aluminum sol is 1: (0.1-2). Immerse the foamed silicon carbide in the slurry for 1 min, remove the excess slurry in the hole after taking it out, and dry it. The dipping and dr...

Embodiment 1

[0029] The first carrier used in the foam structure catalyst for the reaction of benzaldehyde hydrogenation to prepare benzyl alcohol described in this example is silicon carbide foam, and the second carrier is gamma-Al 2 o 3 , the active component is Ni, and the specific preparation steps are as follows:

[0030] (1) Preparation of foamed silicon carbide

[0031] The preparation method of foamed silicon carbide (the first carrier) is based on the preparation method described in the invention patent with application number CN03134039.3 (publication number CN1600742A). The foamed silicon carbide used in this embodiment has a three-dimensional connected porous structure, the number of meshes of silicon carbide is 10PPI, the average size of the foam holes is 2mm, the porosity is 80%, and the volume of the foamed silicon carbide is 5cm 3 .

[0032] (2) Preparation of alumina impregnation slurry

[0033] Weigh 15g of pseudo-boehmite and dissolve it in 100mL of distilled water, ...

Embodiment 2

[0045] The difference from Example 1 is that the mesh number of the foamed silicon carbide is 15PPI, the average size of the foam cells is 1.6mm, and the porosity is 76%.

[0046] The catalytic performance index of the foam structure catalyst used in the hydrogenation of benzaldehyde to prepare benzyl alcohol in this embodiment is: the conversion rate of benzaldehyde is 88.7%, and the selectivity of benzyl alcohol is 98.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com