Thin film transistor substrate, display panel, and laser annealing method

A thin-film transistor and laser annealing technology, which is applied in transistors, laser welding equipment, electric solid-state devices, etc., can solve the problems of low electron mobility and the inability to fully cope with the high electron mobility of display panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

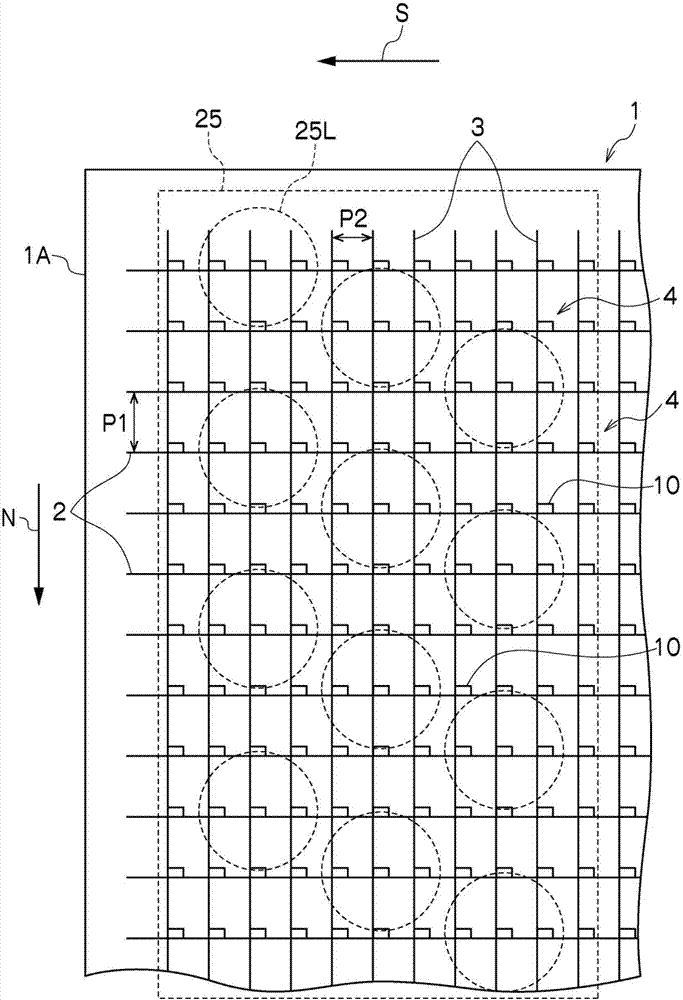

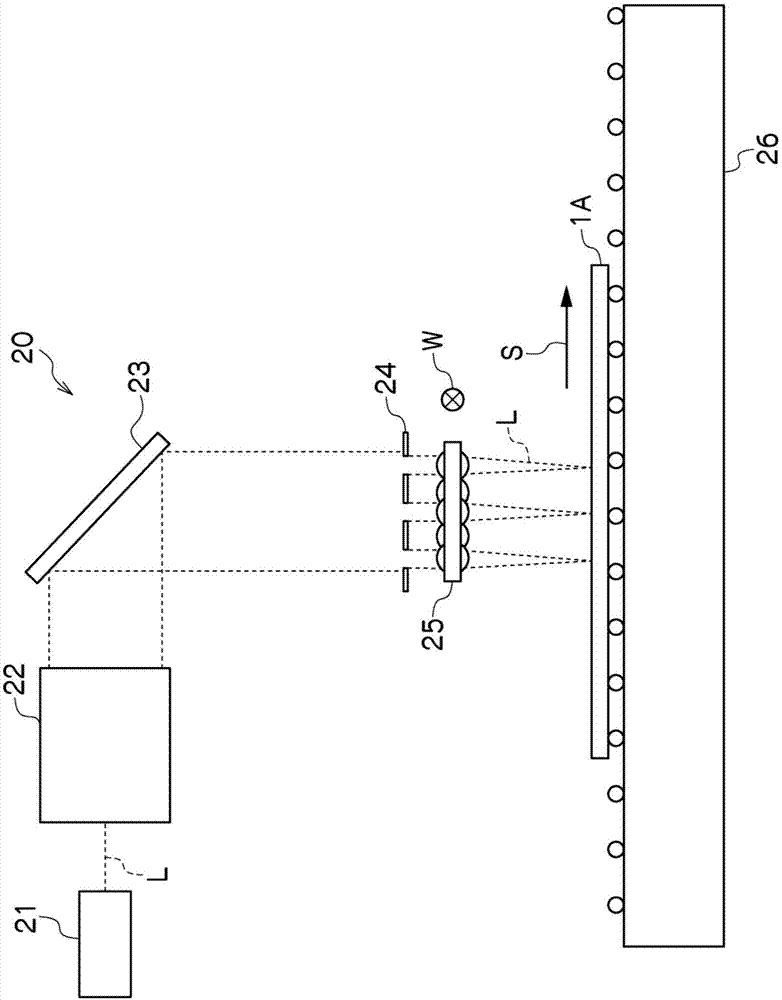

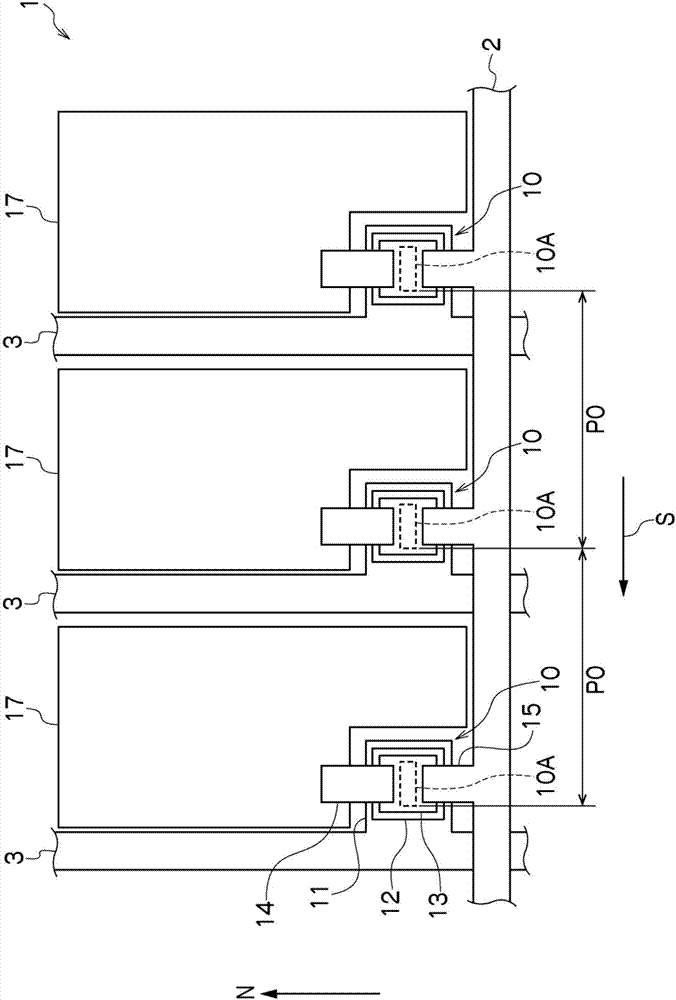

[0022] Hereinafter, embodiments of the present invention will be described with reference to the drawings. Such as figure 1 As shown, in the TFT substrate 1, a plurality of data lines 2 and gate lines 3 are respectively formed in columns and rows on the substrate, and TFTs 10 are formed near the intersections of the data lines 2 and gate lines 3, and each The TFT 10 is provided with a transparent electrode forming portion 4 . In this way, on the TFT substrate 1 , a plurality of TFTs 10 are arranged in columns and rows on the substrate 1A. In the illustrated example, the data lines 2 have a pitch of vertical width P1, and the gate lines 3 have a pitch of horizontal width P2. Correspondingly, the TFTs 10 have a pitch of vertical width P1 in columns and a pitch of horizontal width P2 in horizontal rows. arranged in a dot matrix.

[0023] Laser annealing in the manufacture of TFT substrate 1, such as figure 1 As shown, the pattern of the gate line 3 is formed on the substrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com